Optical quantum generator for oil removing and extraction range hood and preparation method thereof

A range hood and generator technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of low purification rate of lampblack and high energy consumption, and achieve good oil removal efficiency and odor removal effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

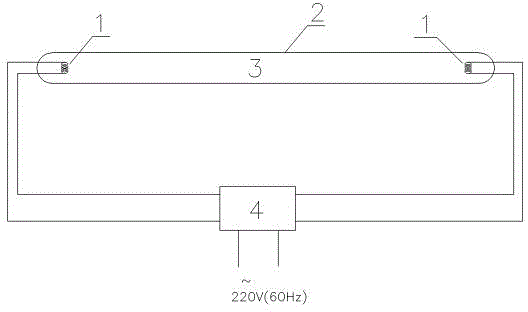

[0038] Such as figure 1 shown.

[0039] A photon quantum generator for extracting range hoods, comprising a filament 1, an excitation gas, a glass tube 2, an inner chamber 3, and a driving power supply 4. Such as figure 1 As shown, the filament 1 is located in the airtight glass tube 2. The main body of the filament 1 is a tungsten wire, and the tungsten wire is covered with a layer of CaO, BaO and Y with a thickness of 1-500 μm. 2 o 3 Ternary metal oxide crystal, the molar composition of ternary metal oxide crystal is: CaO 25-55%, BaO 20-50%, Y 2 o 3 8 to 25%, the sum of the molar components of the ternary metal oxide crystal is 100%. Elementary mixed gas, the molar composition of the ternary mixed gas: Ar 25-35%, Ne 60-74%, Xe0.5-5%, the sum of the molar components of the ternary mixed gas is 100%; driving power 4, It provides electric energy for the light quantum generator lamp tube to work. It can ensure that the temperature of the filament 1 is between 350K~650K be...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that the power of the photon quantum generator is 30-120 watts, and the corrosion degree of the generated 184.9nm photons is 25-70 μw / cm 2 , the generated 253.7nm photon intensity is 60~380μw / cm 2 .

Embodiment 3

[0048] A preparation method of a light quantum generator lamp tube for a range hood, which includes the preparation and assembly of a filament:

[0049] The specific production method of the ternary crystal filament is: mix three kinds of high-purity carbonates by molar ratio of CaCO 3 25-55%, BaCO 3 20-50% and Y 2 (CO 3 ) 3 Accounting for 8-25% mixed and ground into 200-100 mesh mixed powder, the sum of each component is 100%, mixed with a small amount of high-purity water to make slurry, stick to tungsten wire, and dry in a clean room. Slowly heat to 450°C-550°C (optimally 500°C) under an inert atmosphere, then burn at 600-800°C and keep it warm for 0.5 hours (can also be set arbitrarily between 0.3-0.7 hours).

[0050] The quartz tube can be an existing conventional quartz tube, but it is best to use ultra-high purity SiO 2 to increase the transmittance. Ultra-high purity SiO 2 The purity is as follows:

[0051]

[0052] The installation steps are as follows: fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com