Online repair method for window rolling stress surfaces of rack archways of hot continuous rolling units

A force-bearing surface and hot continuous rolling technology, which is applied in the field of on-line repair of the force-bearing surface of the frame archway window rolling of the hot continuous rolling mill, can solve the problems of slow arc surfacing welding speed, unstable deformation of the frame archway structure, structural stress and Large residual stress and other problems, to achieve the effect of improving anti-corrosion and wear resistance, improving repair efficiency, and changing material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

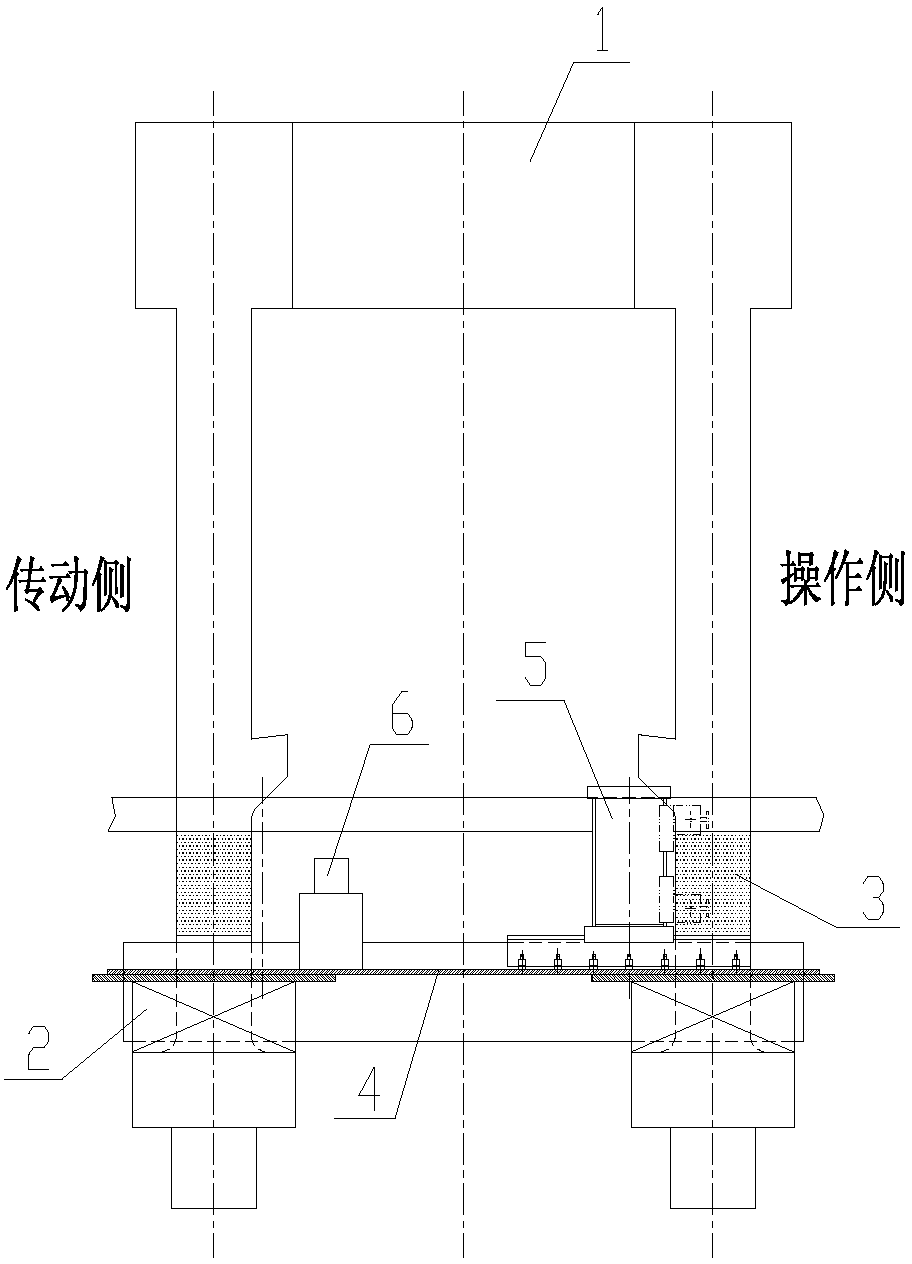

[0015] Such as figure 1 As shown, the online repair method for the rolling force-bearing surface of the window of the frame archway of the hot continuous rolling mill of the present invention includes the following steps:

[0016] Step 1. Build the repairing construction platform 4. Taking the upper plane of the bottom oil cylinder 2 of the rack archway 1 as a benchmark, the construction platform 4 is directly set on the upper plane of the bottom oil cylinder 2 of the rack archway 1, and ensure the strength and rigidity of the construction platform 4;

[0017] Step 2: Use the lifting device to move the mobile boring and milling machine tool 5 into the frame archway 1 and set it on the construction platform 4, adjust the horizontality of the mobile boring and milling machine tool 5 in X and Y directions, and align the movement of the machine tool 5 in the X direction Frame archway 1, window liner 3 force-bearing surface straightness, and retest liner 3 force-bearing surface str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com