Tire retreading process and tire retreading equipment

A tire retreading and tire technology, applied to tires, other household appliances, household appliances, etc., can solve the problems of limited vulcanization temperature, high cost, long operation time, etc., and achieve fast assembly process, low production cost, and good product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

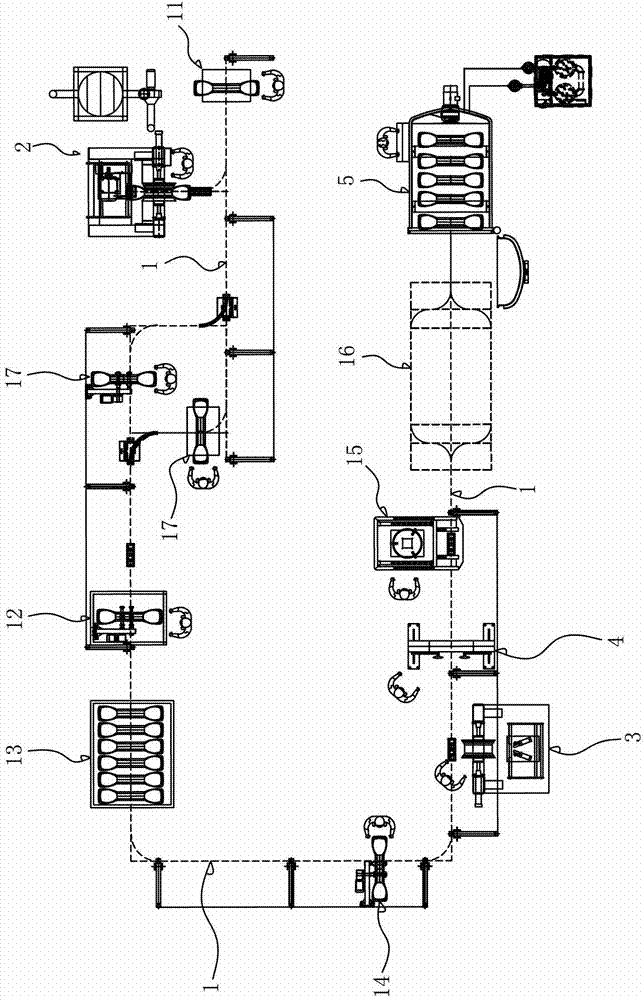

[0056] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0057] A tire retreading process, the steps of the retreading process include:

[0058] a. Preliminary inspection of tires: check the damage degree of tire tread and tire shoulder through manual cooperation with tire testing machine, and select tires whose damage degree does not exceed the standard;

[0059] b. Grinding and cleaning. Use the tire tread grinding machine to evenly grind and roughen the tread of the above-mentioned selected tires, and check the tire tread through the tire inspection machine. If the tread is not evenly ground, it needs to be polished again ; If the tread is evenly ground, clean, patch and fill the wound inside and outside the tire;

[0060] c. Glue brushing and drying treatment, evenly brush glue on the polished and roughened tire tread, and transfer it to a drying room for drying, wherein the drying time is 10-15min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com