Microporous foamed-plastic foaming agent and preparation method thereof

A foamed plastic and foaming agent technology, which is applied in the field of preparation of azodicarbonamide and attapulgite materials, can solve the problems of small loading of foaming agent and the like, and achieve the effect of increasing the loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

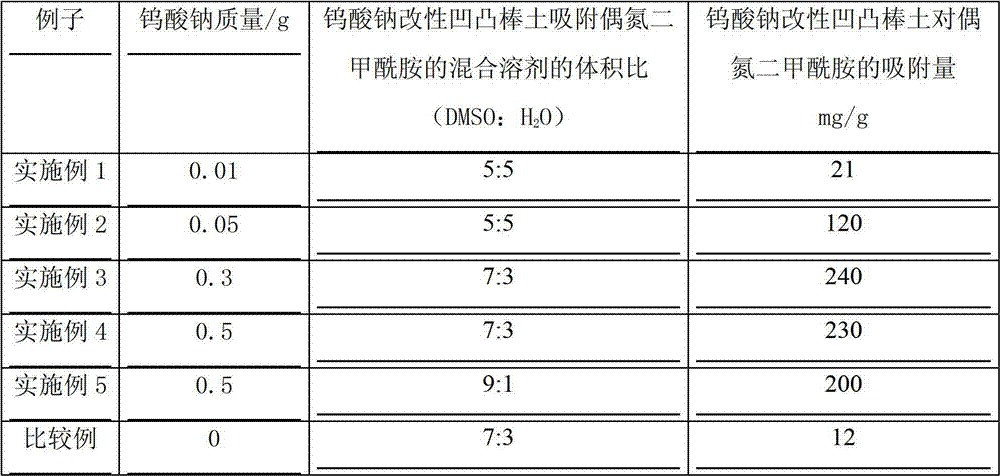

[0019] The method for modifying attapulgite with sodium tungstate is to weigh 0.01g of sodium tungstate, dissolve it in 100g of water, then add 10g of attapulgite, use ultrasonic wave for 30min, and then heat in a constant temperature heating magnetic stirrer at 80°C Stir for 0.5h, then filter with suction, wash 3 times, and dry at 80°C for 12h to obtain sodium tungstate-modified attapulgite.

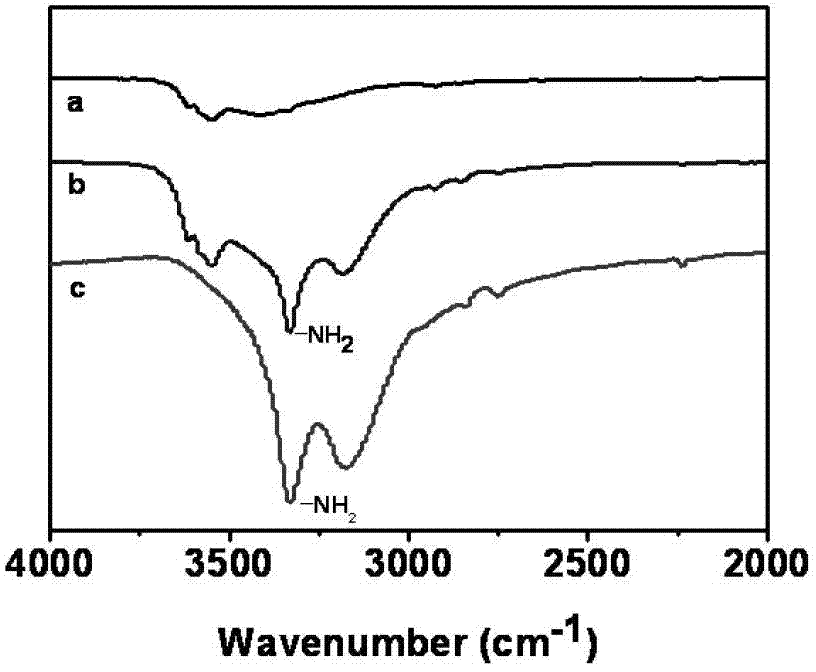

[0020] The adsorption method of sodium tungstate modified attapulgite to azodicarbonamide is as follows: prepare 100ml of a mixed solvent with a volume ratio of dimethyl sulfoxide and water of 1:1, add 200mg of azodicarbonamide, after fully dissolving, add 0.5g of sodium tungstate modified attapulgite, kept at 50°C, stirred for 0.5h, centrifuged, discarded the supernatant, dried at 30°C for 6h, and azodicarbonamide / tungstic acid was obtained Sodium / attapulgite composite foaming agent, analyzed by infrared spectroscopy ( figure 1 ), figure 1 Among them, a is the infrared spectrum of at...

Embodiment 2

[0022] The method of modifying attapulgite with sodium tungstate is to weigh 0.05g of sodium tungstate, dissolve it in 100g of water, then add 10g of attapulgite, use ultrasonic wave for 10min, and then heat in a constant temperature heating magnetic stirrer at 60°C Stir for 2 hours, then suction filter, wash 3 times, and dry at 110°C for 6 hours to obtain sodium tungstate-modified attapulgite.

[0023] The adsorption method of sodium tungstate modified attapulgite to azodicarbonamide is as follows: prepare 100ml of a mixed solvent with a volume ratio of dimethyl sulfoxide and water of 5:5, add 200mg of azodicarbonamide, after fully dissolving, add 0.5g sodium tungstate modified attapulgite, kept at 30°C, stirred for 5h, centrifuged, discarded the supernatant liquid, dried at 60°C for 3h, and azodicarbonamide / sodium tungstate was obtained / Nano attapulgite composite foaming agent. Quantitative analysis of azodicarbonamide in the clarified liquid by UV-Vis spectroscopy. As s...

Embodiment 3

[0025] The method of modifying attapulgite with sodium tungstate is to weigh 0.3g of sodium tungstate, dissolve it in 100g of water, then add 10g of attapulgite, use ultrasonic wave for 30min, and then heat in a constant temperature heating magnetic stirrer at 80°C Stir for 2 hours, then suction filter, wash 3 times, and dry at 105°C for 12 hours to obtain sodium tungstate-modified attapulgite.

[0026] The adsorption method of sodium tungstate modified attapulgite to azodicarbonamide is as follows: prepare 100ml of a mixed solvent with a volume ratio of dimethyl sulfoxide and water of 7:3, add 200mg of azodicarbonamide, after fully dissolving, add 0.5g sodium tungstate modified attapulgite, kept at 50°C, stirred for 2h, centrifuged, discarded the supernatant liquid, dried at 50°C for 5h, and azodicarbonamide / sodium tungstate was obtained / Nano-attapulgite composite foaming agent, quantitative analysis of azodicarbonamide in clarified liquid by ultraviolet-visible spectroscopy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap