Vertical short type internally heated carbonization furnace for dry distillation and oil extraction of slack coal

An internal heat type, coal dry distillation technology, applied in fixed carbonization furnaces, special forms of dry distillation, coking ovens, etc., to achieve the effect of increasing the use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

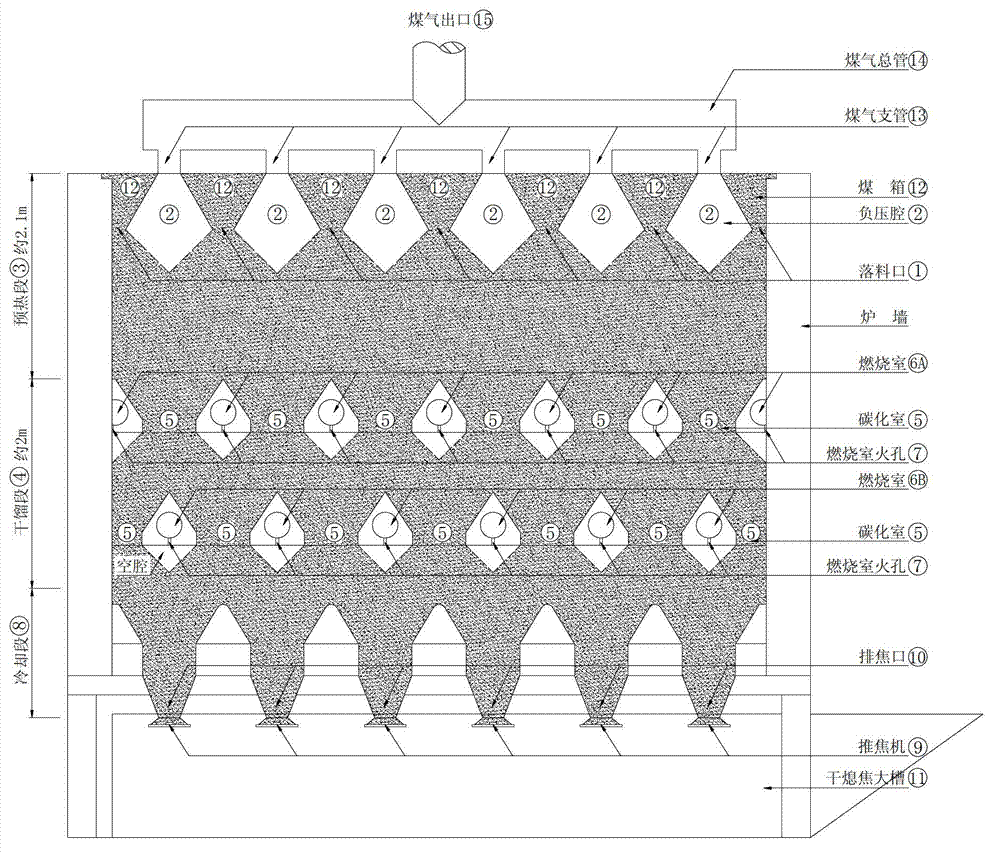

[0021] The overall structure of the upright low type internal heat dry distillation and oil extraction carbonization furnace of this embodiment is shown in the accompanying drawings: it mainly consists of a furnace body, a blanking port 1, a negative pressure chamber 2, a carbonization chamber 5, a combustion chamber, and a combustion chamber. Chamber fire hole 7, coke pushing machine 9, coke discharge port 10, CDQ large groove 11, coal box 12, gas branch pipe 13, gas main pipe 14, and gas outlet 15; it is characterized in that the vertical height of the furnace body is 5.2 m to 5.3m; the upper layer combustion chamber 6A and the lower layer combustion chamber 6B are respectively arranged under the blanking port 1, and the two layers of combustion chambers are arranged in a staggered manner.

[0022] The blanking port 1 is a box funnel with a large top and a small bottom, with a length of 3m±0.1 and a width of the lower opening of 22cm±0.1. The vertical height from the blankin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com