Registration mechanism-based multi-point temperature measurement control system

A control system and mechanism technology, applied in thermometers, measuring devices, measuring heat, etc., can solve problems such as scalability limitations, manual control can not meet intelligent control, multiple I/O port resources, etc., to achieve simple maintenance and flexible interaction methods The effect of various and strong expansion capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

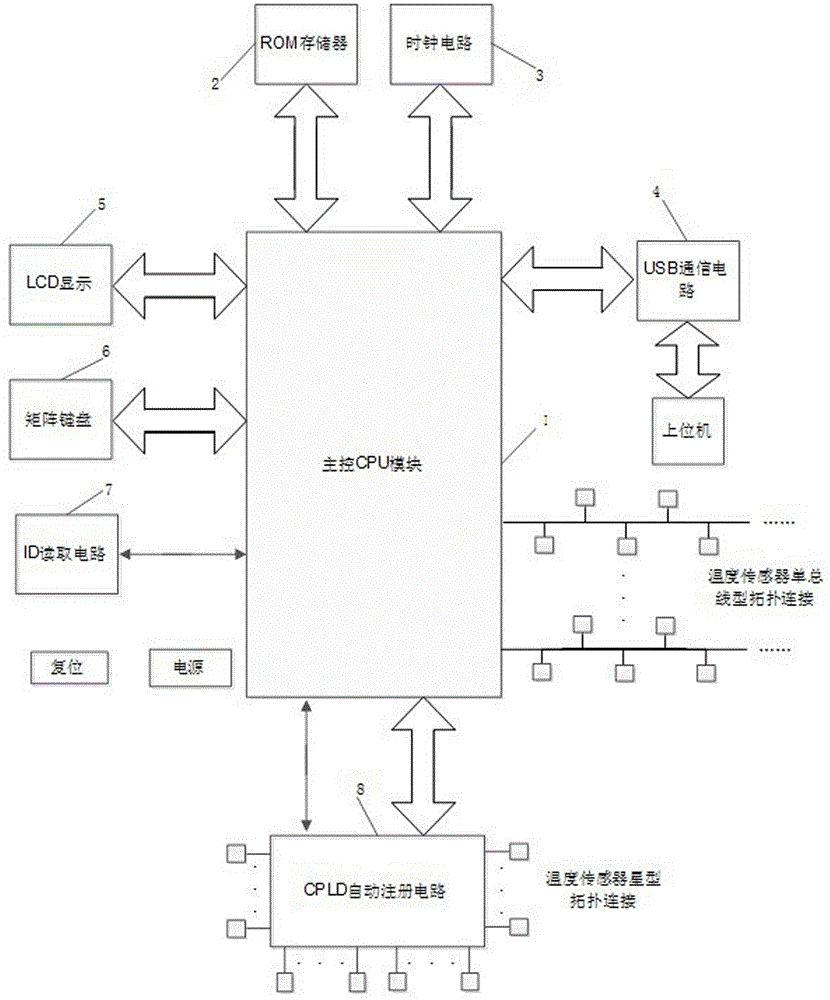

[0025] as attached figure 1 The schematic block diagram of the multi-point temperature measurement control system based on the registration mechanism of the present invention is shown. The patented system device is divided into five parts:

[0026] 1. CPU main control system This part is the processing core of the whole system. It is responsible for the processing of the collected temperature data and the identification of the sensor ID, and then transmits the corresponding information to the host computer, and saves the information confirmed by the host computer in the external storage module;

[0027] 2. Automatic registration circuit This part is used to register the sensor ID of the star connection in the system, and associate the address line connected between the CPU and the CPLD with the sensor ID on each IO port of the CPLD o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com