Method for removing photoresist layer

A photoresist layer and wet etching technology, applied in the semiconductor field, can solve the problems of high equipment requirements, complex process conditions, insufficient removal of the photoresist layer, etc., and achieve the effect of simple and effective removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

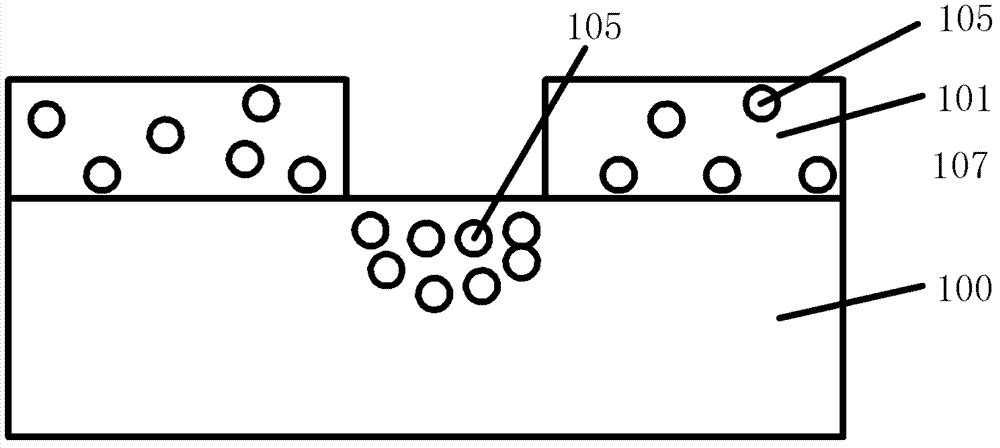

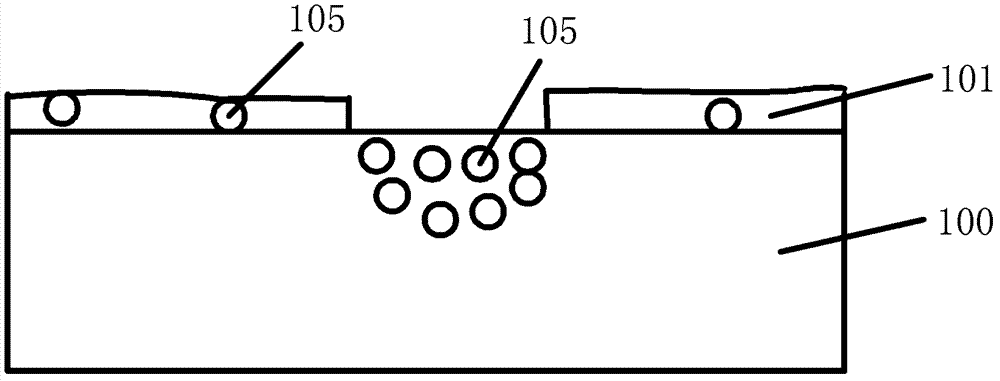

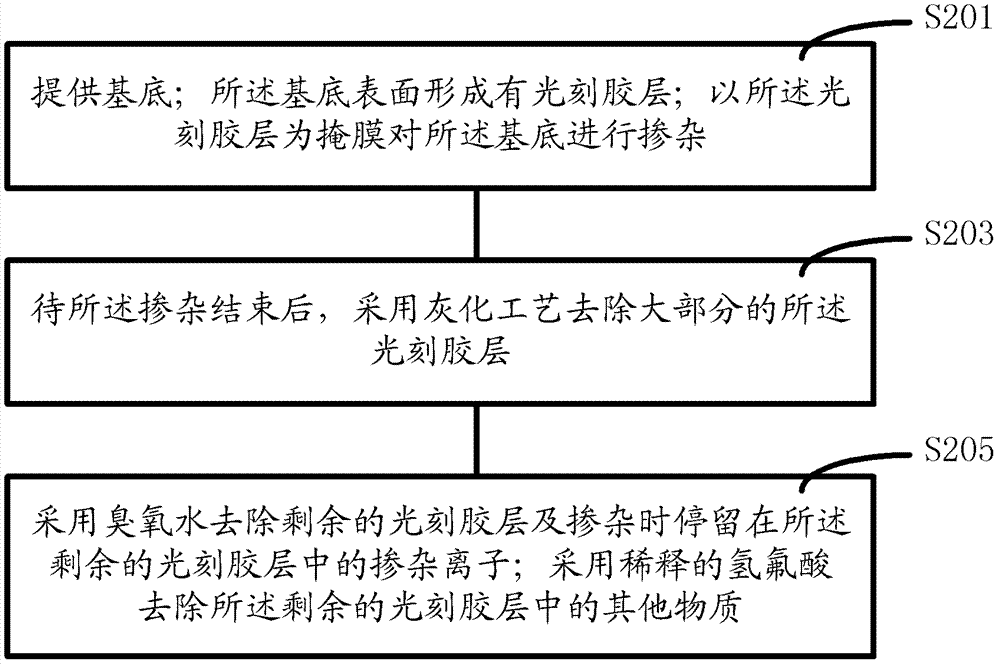

[0026] As mentioned in the background art, the method for removing the photoresist layer in the prior art does not completely remove the photoresist layer. Please continue to refer Figure 1 ~ Figure 2 , the inventor found after research that in the prior art, the photoresist layer 105 is used as a mask to implant ions 105 into the substrate 100. The photoresist layer 101 becomes hard; on the other hand, when implanting ions into the substrate 100, a part of the ions 105 stay in the photoresist layer 101; on the other hand, when implanting ions into the substrate 100, the substrate 100 Part of the silicon atoms in the photoresist layer 101 are inevitably splashed into the photoresist layer 101 under the bombardment of the ions 105; Part of the by-products produced by the reaction of the resist layer will also remain in the photoresist layer. All of the above factors will affect the removal of the photoresist layer 101 .

[0027] After research, the inventors found that at f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com