Yam automatic cleaning and sorting production line

An automatic cleaning and production line technology, applied in sorting, application, food processing, etc., can solve problems such as low work efficiency and inability to adapt to the needs of automated production, and achieve reduced labor intensity, improved automation level and production efficiency, and efficient automatic cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

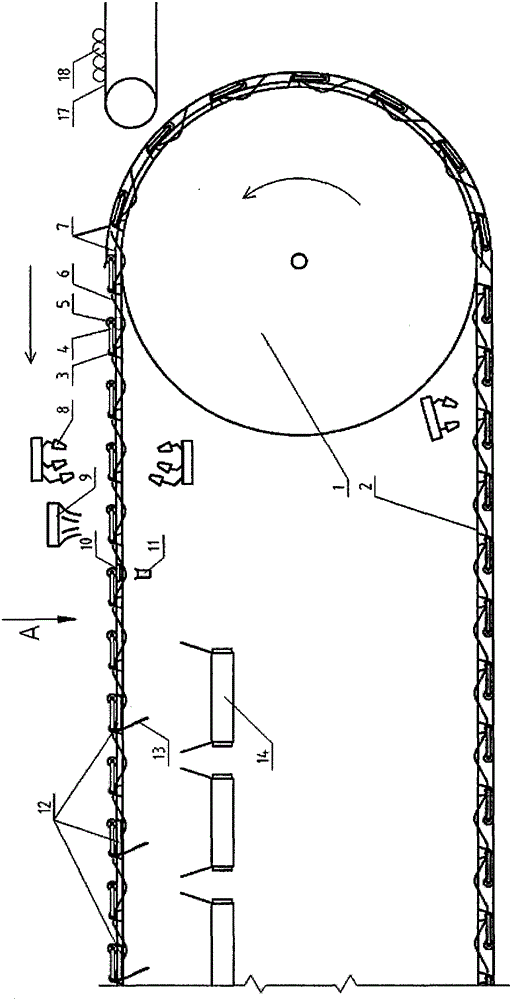

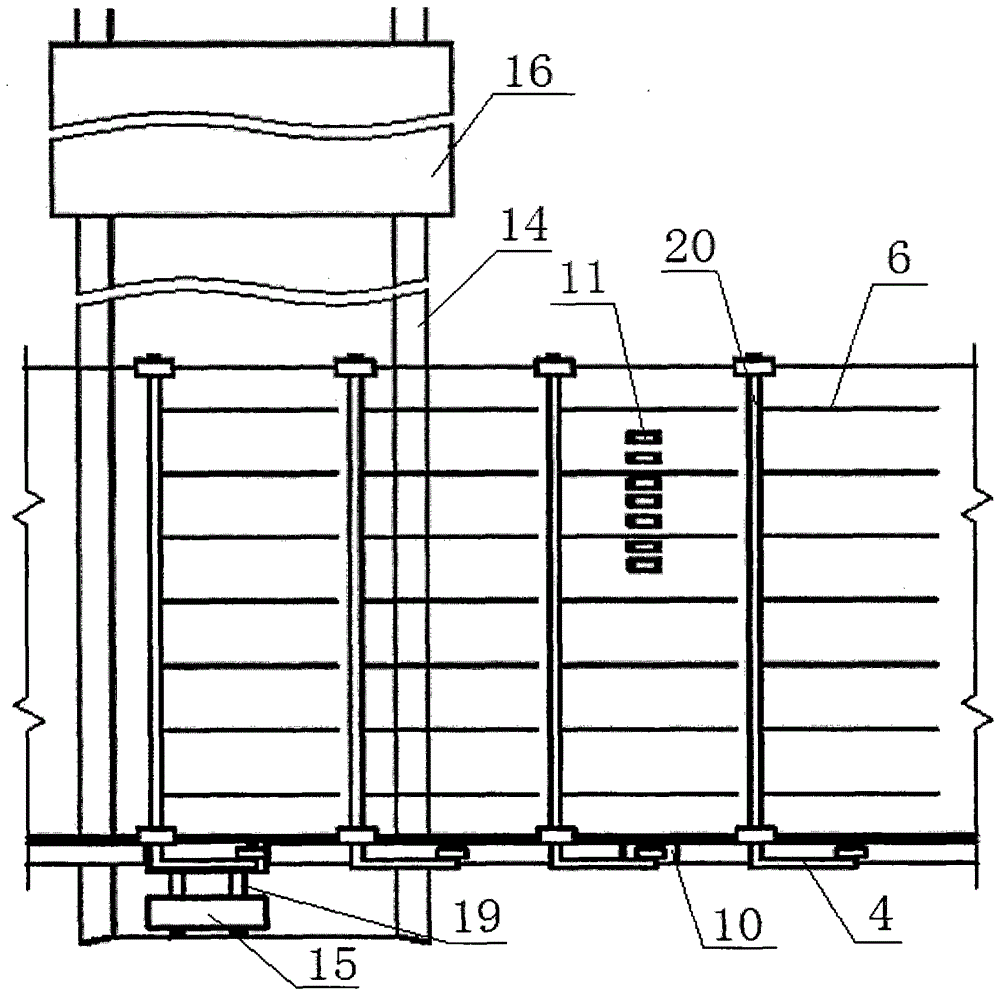

[0018] refer to Figure 1-Figure 2 The yam automatic cleaning and sorting production line of the present embodiment is connected with the PLC control system, and it includes a belt conveyor 17, a conveying device, a supporting device, a rough cleaning device, a comprehensive measuring device, and a sorting and conveying device arranged on the frame. device, fine cleaning device, belt conveyor 17 is connected with the supporting device arranged on the conveying device, and the rough cleaning device, comprehensive measuring device, sorting conveying device, and fine cleaning device are arranged in sequence.

[0019] The conveying device comprises two pairs of driving sprockets 1, a pair of chains 2, and guide rails, and the pair of chains 2 meshes with the two pairs of driving sprockets 1 respectively to form two chain conveyor chains, and the two conveyor chains are arranged symmetrically, and Corresponding driving sprocket 1 is connected by shaft, and described guide rail is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com