Preparation method and application of separation film with nano composite cortical layer

A composite skin, separation membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology and other directions, can solve the problems of membrane water flux and other performance degradation, to overcome the lack of mechanical strength, widen the range of materials, The effect of high retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Dissolve 500g of silica nanoparticles (particle size 5nm) in 2200g of N,N-dimethylpyrrolidone, stir and disperse evenly, then add 500g of polysulfone, the dissolution temperature is 80°C, and the dissolution time is 8h, and the dissolved solution is placed in a vacuum oven Stand at 40°C for degassing, the degassing time is 7 hours, and the solution after degassing is evenly applied to the upper and lower layers of the non-woven fabric substrate at the same time using the upper layer coating die head, the coating speed is 10m / min, and the coating thickness is the upper layer 0.5 μm, lower layer 20 μm. The coating solution layer was coagulated in deionized water at a coagulation bath temperature of 25°C. After coagulation, the obtained ultrafiltration membrane was rinsed in deionized water to remove residual solvent and stored in deionized water.

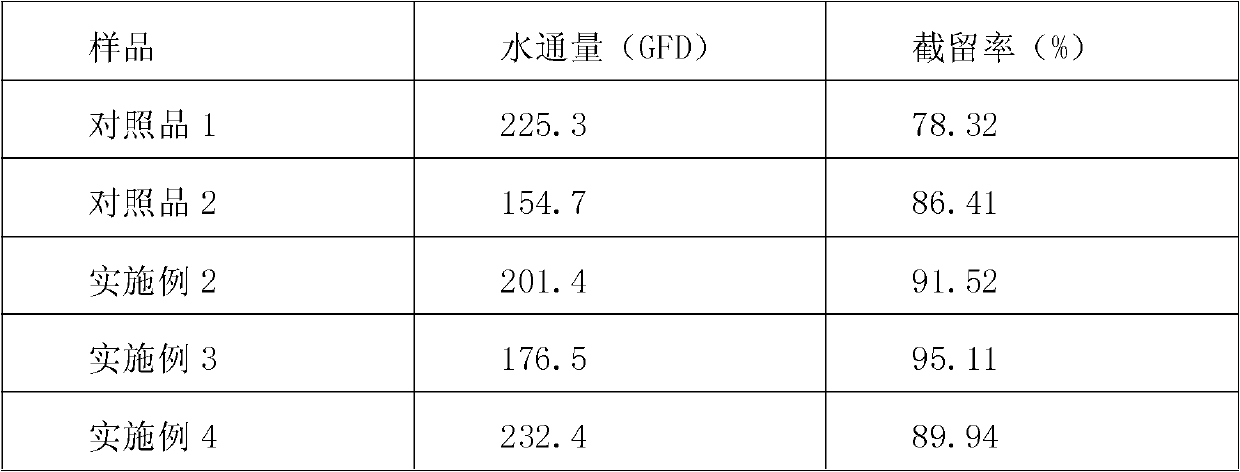

Embodiment 2

[0030] First, disperse 54g of titanium dioxide nanoparticles (particle size: 60nm) in 2646g of dimethylacetamide, stir and disperse evenly, add 500g of polycarbonate, stir and dissolve, the dissolution temperature is 80°C, and the dissolution time is 8h, and the dissolved solution is placed in a vacuum Stand in an oven at 40°C for defoaming, and the defoaming time is 7 hours. After defoaming, the solution is evenly applied to the upper and lower layers of the non-woven fabric substrate at the same time using the upper coating die head. The coating speed is 10m / min, and the coating thickness is The upper layer is 5 μm, and the lower layer is 50 μm. The coating solution layer was coagulated in deionized water at a coagulation bath temperature of 25° C. After coagulation, the obtained ultrafiltration membrane was rinsed in deionized water to remove residual solvent and stored in deionized water.

Embodiment 3

[0032] Dissolve 500g of polyethersulfone in 2200g of chloroform, the dissolution temperature is 80°C, and the dissolution time is 8h. The dissolved solution is placed in a vacuum oven at 40°C for defoaming, and the defoaming time is 7h. Polymer solution A in the bulk layer.

[0033] Disperse 54g of zinc oxide nanoparticles (particle size 100nm) in 2646g of chloroform, stir and disperse evenly, add 500g of polyethersulfone, stir and dissolve, the dissolution temperature is 80°C, and the dissolution time is 8h, and the dissolved solution is placed in a vacuum oven Stand at 40° C. for defoaming for 7 hours to prepare polymer solution B for the nanocomposite skin layer.

[0034] The above solutions A and B are uniformly applied on the non-woven fabric substrate at the same time using a double-layer coating die head, the coating speed is 10m / min, the coating thickness of the lower layer (body layer) is 100 μm, and the coating thickness of the upper layer (skin layer) is 10 μm. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com