Preparation method of self-activation laser crystal phosphoric acid trisneodymium

A technology of laser crystal and tri-neodymium phosphate, which is applied in crystal growth, chemical instruments and methods, and self-melting solvent melt, etc., to achieve the effect of high conversion efficiency and high concentration of activated ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

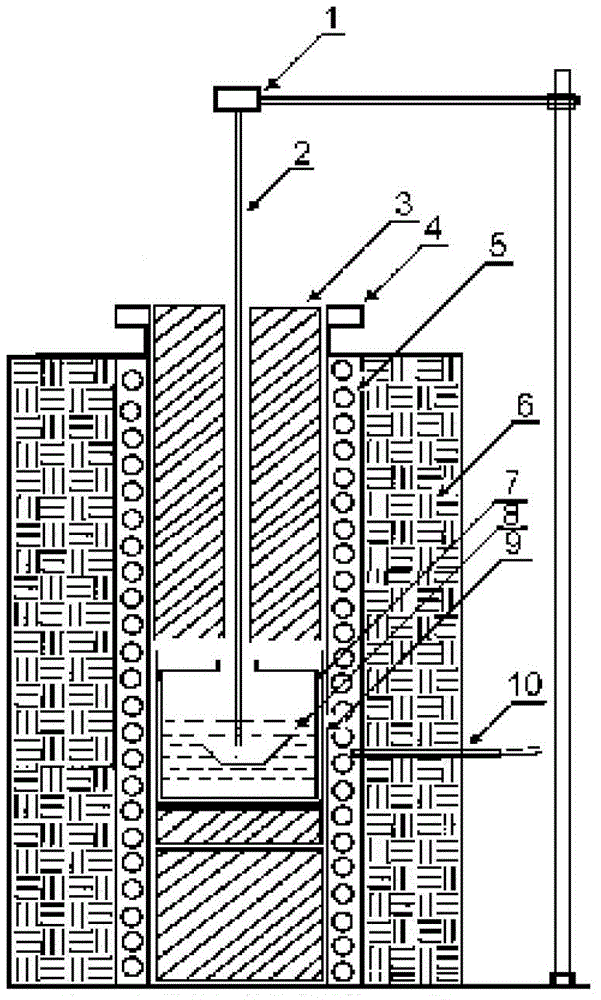

[0025] figure 1 The method of the present invention is used to grow Nd 3 PO 7 Schematic diagram of the crystal device structure. The device is a vertical resistance wire heating furnace. The seed rod 2 extends into the melt 8 and rotates under the drive of the rotating device 1. The furnace tube 4 is equipped with refractory bricks 3, and the resistance wire 5 is wound around the outer wall of the furnace tube 4 , Its outer layer is insulation material 6. The temperature control equipment is a FP21 programmable automatic temperature controller with a temperature control accuracy of 0.1% in the growth temperature area. The crystal incubator 7 is placed in the alumina crucible 9, which is a platinum crucible of 70×90 mm, which can withstand the working temperature below 1774°C, and the contained melt is not easy to cause corrosion to it. The thermocouple 10 uses PtRh / Pt, which can effectively control the growth temperature.

Embodiment 2

[0031] Choose lithium carbonate-tungsten oxide (Li 2 CO 3 -WO 3 ) Combination flux with a molar ratio of 1:1, raw material is 3N Nd 2 O 3 And 3NNH 4 H 2 PO 4 ,According to ammonium dihydrogen phosphate: neodymium oxide=3:2, mix it evenly and put it in a platinum crucible, control the concentration of the solute (ammonium dihydrogen phosphate + neodymium oxide) to 25wt%, and heat up to 1000℃ to melt the material.

[0032] The temperature is raised to 1030°C and the temperature is kept constant for 30 hours. After the material is fully melted, it is stirred to make the melt fully mixed and uniform. Measure the saturation point temperature of the solution by the seed crystal trial method, choose a better quality seed crystal to grow, introduce the seed crystal into the growth furnace when the temperature is 12 ℃ higher than the solution saturation point temperature, and place the seed crystal in a proper position above the liquid surface before fully preheating it. Then the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com