Device and method for spinning nanofiber and filament composite yarns

A nanofiber and filament technology, applied in the direction of filament/thread forming, fiber treatment, yarn, etc., can solve problems such as easy peeling, and achieve the effect of high strength characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: The spinning method of nanofiber and filament composite yarn adopts the following process steps:

[0029] (1) Mix acetone:dimethylacetamide into a uniform spinning solvent at a volume ratio of 2:1, and dissolve cellulose diacetate with a molecular weight distribution of 30,000 and an acetylation of 39.8% in the spinning solvent. Stir at 25°C for 12 hours at room temperature to obtain a uniform spinning solution. The mass fraction of cellulose diacetate in the spinning solution is 11%;

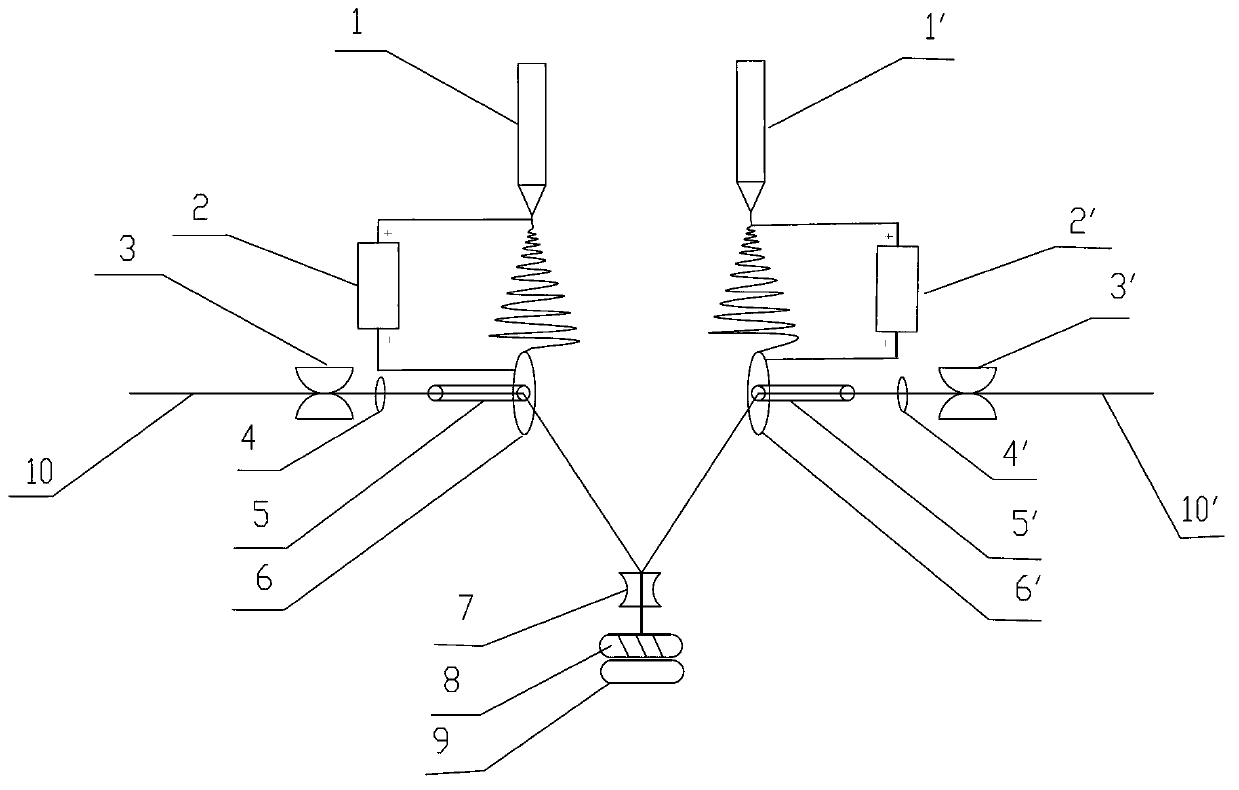

[0030] (2) Add the spinning solution to the two spinning solution injectors for electrospinning. The distance between the two spinning solution injectors is 15cm, and the distance between the yarn guide and the nanofiber receiving plate is 15cm; spinning The liquid injector is connected to the positive electrode of the high-voltage power supply, and the nanofiber receiving plate is connected to the negative electrode of the high-voltage power supply; the electrospinning voltage ...

Embodiment 2

[0033] Embodiment 2: The spinning method of nanofiber and filament composite yarn adopts the following process steps:

[0034] (1) Dissolve polyacrylonitrile with a relative molecular mass of 75000 in dimethylacetamide and stir for 12 hours at 28°C at room temperature to obtain a uniform spinning solution. The mass fraction of polyacrylonitrile in the spinning solution is 10%;

[0035] (2) Add the spinning solution to the two spinning solution injectors separately, the distance between the two spinning solution injectors is 10cm, the distance between the yarn guide and the receiving plate is 10cm; the spinning solution injector is connected to the positive electrode of the high-voltage power supply , The nanofiber receiving plate is connected to the negative electrode of the high-voltage power supply, the electrospinning voltage is 30kV, the spinning speed is 0.5ml / h, the spinning environment temperature is 28℃, the relative humidity of the spinning environment is 50%RH, the nanofi...

Embodiment 3

[0038] Embodiment 3: The spinning method of nanofiber and filament composite yarn adopts the following process steps:

[0039] (1) Dissolve polylactic acid with an average molecular weight of 10,000 in dichloromethane and stir for 12 hours at 25°C and room temperature to obtain a uniform spinning solution. The mass fraction of polylactic acid in the solution is 8%;

[0040] (2) Add the spinning solution to the two spinning solution injectors respectively, the distance between the two spinning solution injectors is 8cm, the distance between the yarn guide and the nanofiber receiving plate is 8cm; the spinning solution injector is connected to high pressure The positive pole of the power supply, the nanofiber receiving plate is connected to the negative pole of the high-voltage power supply, the electrospinning voltage is 15kV, the spinning speed is 0.8ml / h, the spinning environment temperature is 25℃, and the relative humidity of the spinning environment is 60%RH. The distance betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com