Observation hole lining of ceramic fiber modules

A technology of ceramic fiber and ceramic fiber blanket, which is applied in the field of fire hole lining of ceramic fiber modules for industrial furnaces, can solve the problems of narrow viewing angle space, different linear expansion coefficients, and high and low inequality, and achieve simple and convenient installation and maintenance. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

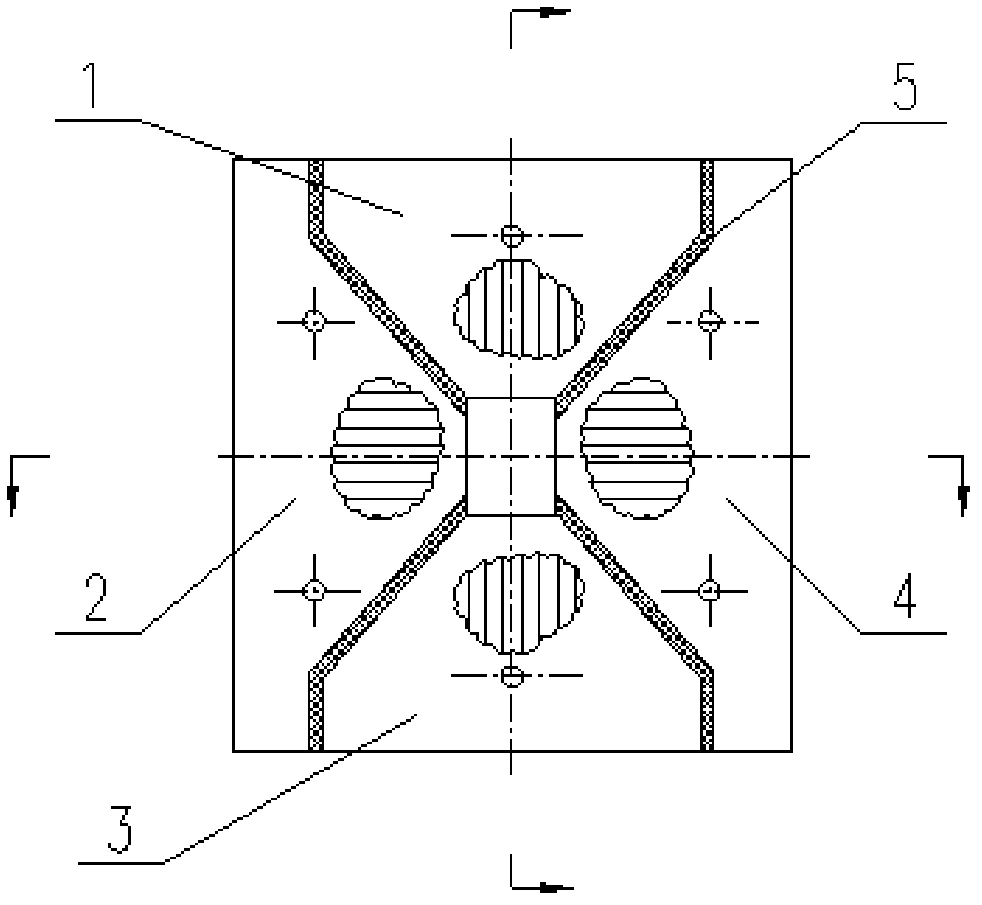

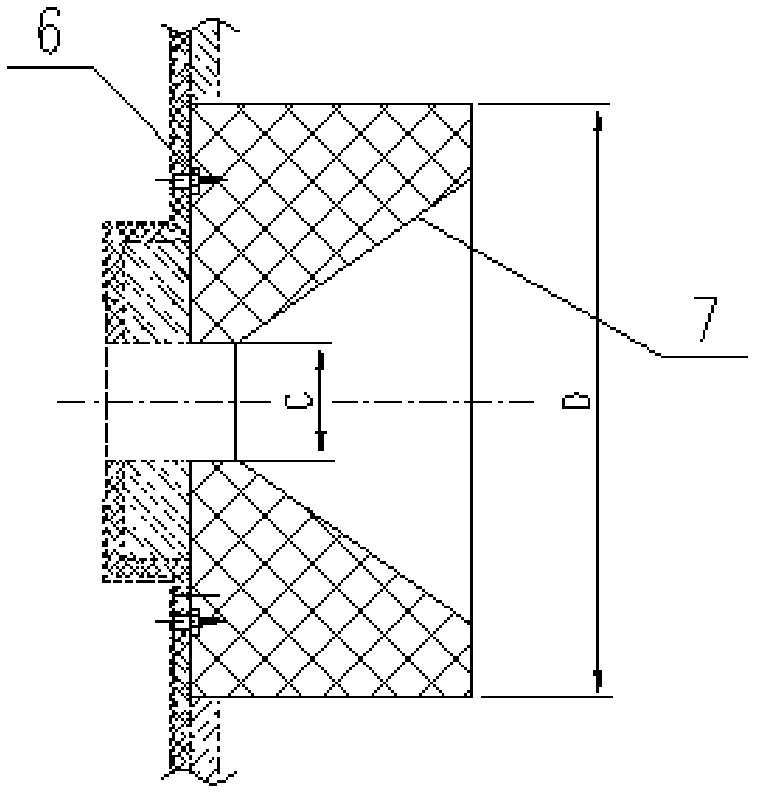

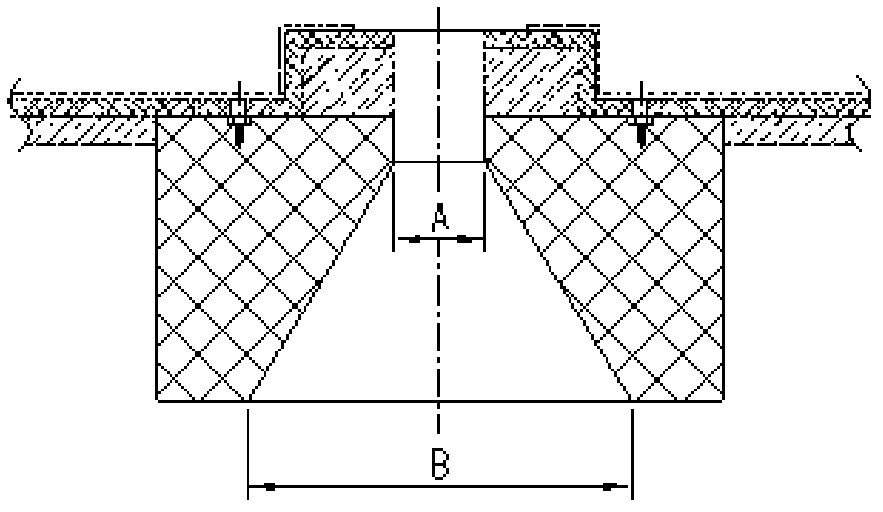

[0050] A fire hole lining for ceramic fiber modules, comprising module one 1, module two 2, module three 3, module four 4, ceramic fiber blanket 5, installation anchors 6 and anti-scouring high temperature paint 7. The center of the lining is a fire viewing hole, in which module one 1, module two 2, module three 3, and module four 4 are made of ceramic fiber blankets folded and pre-embedded with anchors, and the ceramic fiber blankets of module one 1 and module three 3 It is compressed along the horizontal direction, and the ceramic fiber blankets of module two 2 and module four 4 are compressed along the vertical direction. Four modules are arranged around the fire hole, forming an inverted funnel-shaped space in the middle. The viewing angle space of each module is made in the seller's workshop according to the viewing angle space dimensions (A, B, C, D), without cutting the viewing angle space on site, and the inner surface of each module is folded and formed.

[0051] Mod...

Embodiment 2

[0055] Such as Figure 4~6As shown, a ceramic fiber module firehole lining, the basic structure is the same as that of embodiment 1, the difference is that each module is composed of two modules with the same compression direction, that is, the firehole lining includes eight modules, module A1 -1, module B1-2, module C2-1, module D2-2, module E3-1, module F3-2, module G4-1, module H4-2; composed of module A1-1, module B1-2, module The ceramic fiber blankets of E3-1 and module F3-2 are compressed in the horizontal direction, and the ceramic fiber blankets of modules C2-1, D2-2, G4-1 and H4-2 are compressed in the vertical direction.

[0056] Each module is equipped with two installation anchors, and each module is fixed to the inner wall of the furnace through the anchors;

[0057] A layer of ceramic fiber blanket 5 with a thickness of 25 mm is evenly laid between the modules with different compression directions, and the ceramic fiber blanket 5 is compressed to 15 mm during i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com