Diffusing process of low-square resistance crystalline silicon cell

A crystalline silicon battery and diffusion process technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as being unfavorable to improve short-wave spectral response and open circuit voltage, and the depth of p-n junction is not large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

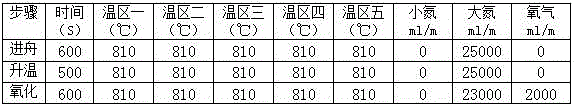

[0036] In this embodiment, the diffusion furnace is selected from the 48th Research Institute of China Electronics Technology Group Corporation. There are five heaters in the diffusion furnace, which are divided into five temperature zones. This diffusion process is carried out under the premise of keeping other process steps unchanged. The first three steps of diffusion process are as follows (Table 3):

[0037] table 3:

[0038]

[0039] A three-step temperature-raising diffusion method is adopted, and the specific diffusion steps are as follows:

[0040] In the first step, the diffusion temperature is maintained at a low level, and the reaction rate is very slow, so as to realize pre-diffusion and deposit phosphorus source on the surface.

[0041] The second step is to increase the temperature and diffuse to promote the decomposition of the phosphorus source and the diffusion into the silicon, and at the same time increase the concentration of the phosphorus source on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com