High-speed magnetic suspension electric main shaft for five-freedom numerically-controlled machine tool

A magnetic levitation electric spindle and CNC machine tool technology, applied in the direction of electromechanical devices, bearings, electrical components, etc., can solve the problems of not reaching high speed, ultra-high speed, short, at most only thousands of hours, and lengthening of the axial length of the motor. Achieve the effect of breaking through the limitations of high power and ultra-high speed, improving the trouble-free running time and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

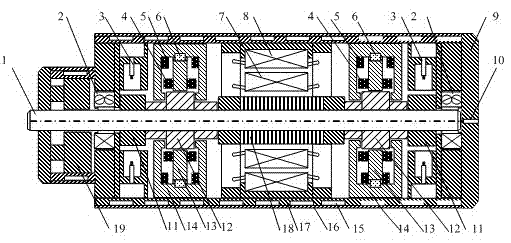

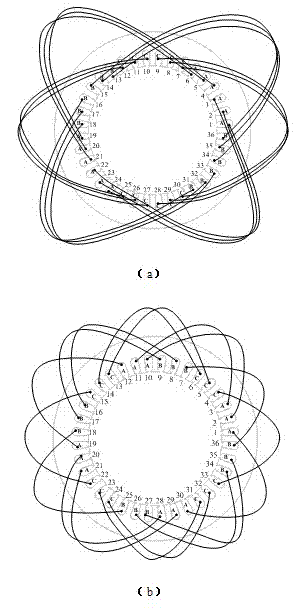

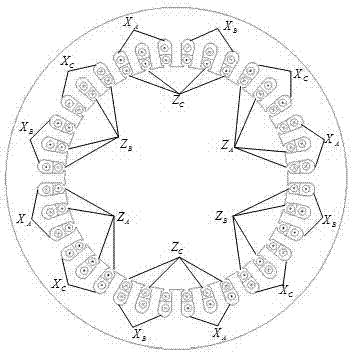

[0017] According to the levitation mechanism of the two-degree-of-freedom magnetic levitation asynchronous motor and the three-degree-of-freedom AC-DC hybrid magnetic bearing, a symmetrical stable structure consisting of a two-degree-of-freedom magnetic levitation asynchronous motor and two three-degree-of-freedom AC-DC hybrid magnetic bearings is proposed. Five-degree-of-freedom CNC machine tool high-speed magnetic levitation electric spindle, any combination of three-degree-of-freedom AC-DC hybrid magnetic bearing and two-degree-of-freedom magnetic levitation asynchronous motor can form a five-degree-of-freedom magnetic levitation asynchronous motor, shortening the high-speed asynchronous motor supported by two magnetic bearings The axial length of the magnetic levitation electric spindle of the motor improves the operation stability of the electric spindle and can realize high-speed and ultra-high-speed operation. The present invention adopts the motor design module RMxprt 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com