Automatic weld fillet removing method and automatic weld fillet removing device for plastic-steel door and window welding machine

A technology for plastic steel doors and windows, welding machine, applied in the field of plastic molding or connection, can solve the problems of increasing equipment cost, reducing production efficiency, increasing manpower, material resources, etc., to reduce the total cost of equipment, improve production efficiency, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

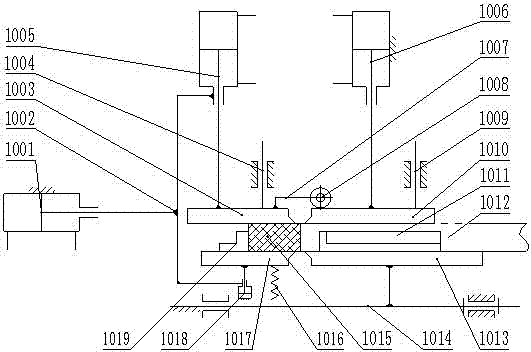

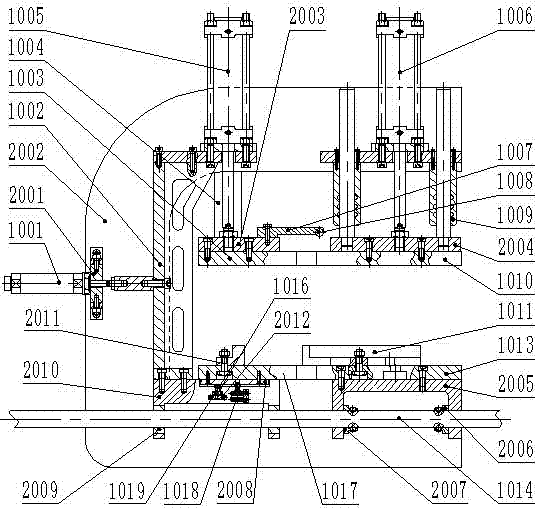

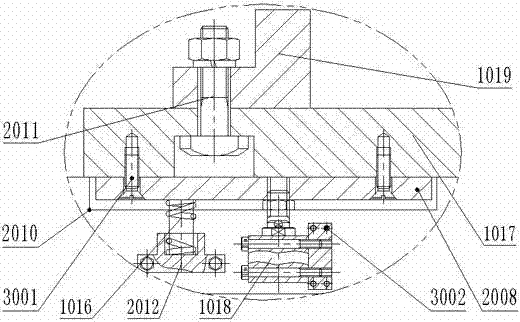

[0022] See attached figure 1 , after the welding step is completed, the first weldment 1012 and the second weldment 1015 are butt-jointed and solidified into one body, and are clamped and fixed by the rear upper clamp 1003, the rear lower clamp 1017, the front upper clamp 1010, and the front lower clamp 1013 respectively. At this time, the temperature of the welding seam is still high, and the performance of the welding bump is relatively soft. The welding corner cleaning step adopts PLC to sequentially control the opening and closing of each air valve, control the action of the corresponding cylinder, and realize the steps in sequence:

[0023] (1) The front upper pressure cylinder 1006 releases the pressure, the front upper pressure clamp 1010 can move freely, and the assembly of weldment one 1012 and weldment two 1015 is clamped and fixed by the rear upper pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com