Full circle swinging propeller hydraulic distance-adjusting mechanism

A technology of propeller and full rotation, which is applied in the direction of ship propulsion, ship parts, ships, etc., can solve the problems affecting the efficiency of propeller propulsion, the structural layout of the lower gearbox, and the economical efficiency of the propeller, so as to simplify the structural layout and save shafts. The effect of arranging space to ensure work efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

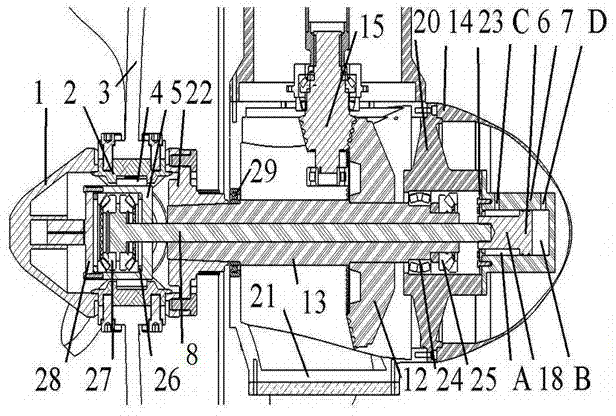

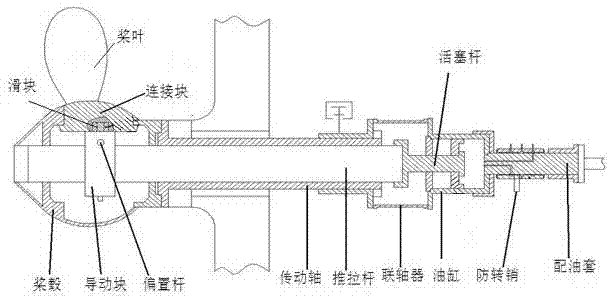

[0022] refer to figure 2 , the hydraulic cylinder 7 and the hydraulic piston 6 are located at the front end of the hub 1 and the blade 3 . The paddle connecting block 2 and the paddle 3 are fixed together by bolts, and the paddle connecting block 2 cooperates with the opening on the propeller hub 1 with a gap, and can rotate in the opening of the propeller hub 1 . The paddle connecting block 2 is connected with the guide block 5 through the offset slider distance adjustment mechanism 4 at the same time, and moves with the guide block 5 .

[0023] The hydraulic piston 6 is fixedly connected to the front end of the piston rod 18, and the rear end of the piston rod 18 is coaxially and fixedly connected in series with the front end of the push-pull rod 8. Through the through hole, and can move forward and backward along the axis, the rear end of the hydraulic cylinder 7 is connected to the bearing sleeve 20, and the bearing sleeve 20 is coaxial with the push-pull rod 8, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com