Mirror varnishing rubber sole and manufacturing method thereof

A technology of rubber sole and bright light, which is applied in the direction of shoe soles, footwear, applications, etc., can solve the problems of affecting the appearance and effect of shoe soles, the poor mirror gloss effect of rubber soles, and the inability to achieve paint products, etc., so as to reduce labor costs and material costs , Avoid the problem of excessive heavy metals, the effect of excellent mirror light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

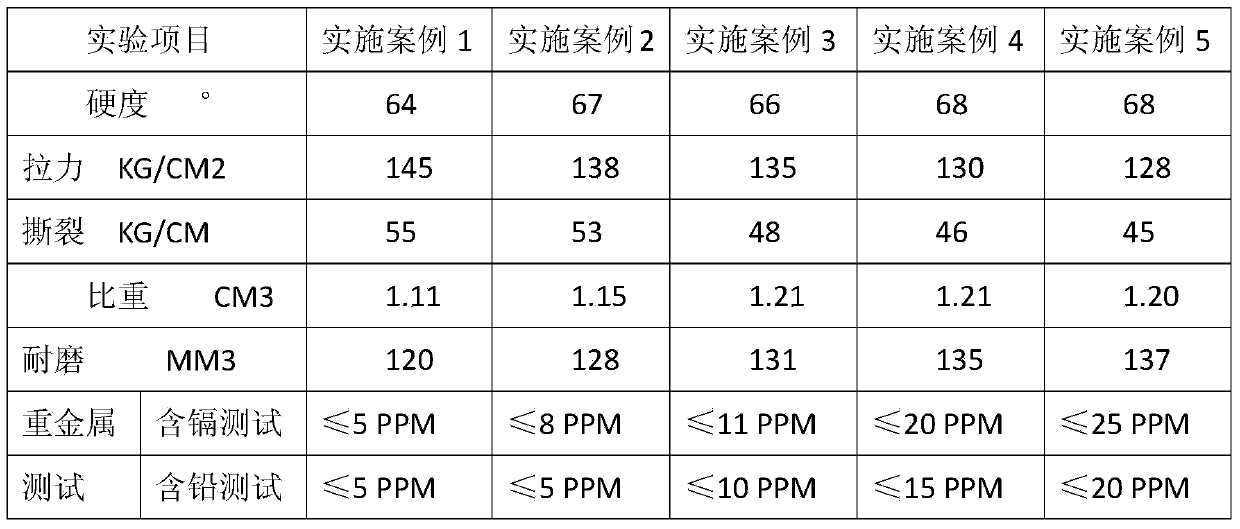

Examples

Embodiment 1

[0025] Bright rubber sole of the present invention is made of the component of following mass parts: 60 parts of acrylonitrile-butadiene rubber (NBR); 40 parts of PVC glue; Silica (SiO 2 ) 35 parts; 6 parts of plasticizer cyclohexane-1,2-diisononyl dicarboxylate; 5 parts of zinc oxide; 1 part of stearic acid; 1 part of anti-aging agent BHT; 1 part of accelerator DM; accelerator M0.5 1 part; 1 part of magnesium oxide; 1.5 parts of ozone inhibitor thiourea dioxide.

[0026] Production Method:

[0027] 1) take each component by above-mentioned mass ratio;

[0028] 2) Put various components into the internal mixer for mixing, the mixing time is 5-10 minutes, and the mixing temperature is 140°C;

[0029] 3) According to the thickness requirements of different soles, the mill is used to press the tablet, and the cutting machine is used to punch out the rubber material;

[0030] 4) Vulcanize in the mold, the vulcanization temperature is 160-170°C, and the molding time is 300-450 s...

Embodiment 2

[0033] The bright rubber sole of the present invention is made of the following components by mass: 55 parts of nitrile rubber (NBR); 45 parts of PVC glue; 45 parts of silicon dioxide; plasticizer cyclohexane-1,2-dicarboxylic acid dicarboxylate 7 parts of isononyl ester; 5.5 parts of zinc oxide; 1 part of stearic acid; 2 parts of antioxidant BHT; 1.5 parts of accelerator DM; 0.5 parts of accelerator M; 1 part of magnesium oxide; 2 parts of ozone inhibitor thiourea derivative .

[0034] The preparation method is the same as in Example 1.

Embodiment 3

[0036] The bright rubber sole of the present invention is made of the following components by mass: 50 parts of nitrile rubber (NBR); 50 parts of PVC glue; 50 parts of silicon dioxide; plasticizer cyclohexane-1,2-dicarboxylic acid di 8 parts of isononyl ester; 6 parts of zinc oxide; 1.5 parts of stearic acid; 2 parts of anti-aging agent BHT; 1.5 parts of accelerator DM; 0.5 parts of accelerator M; 2 parts of magnesium oxide; .

[0037] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com