Preparation method of continuous glass fiber/nylon composite and application thereof

A nylon composite material and glass fiber technology, which is applied in the field of continuous glass fiber/nylon composite material and its preparation, can solve problems such as poor fluidity, poor impregnation effect of continuous glass fiber reinforced composite materials, and high viscosity of ordinary nylon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

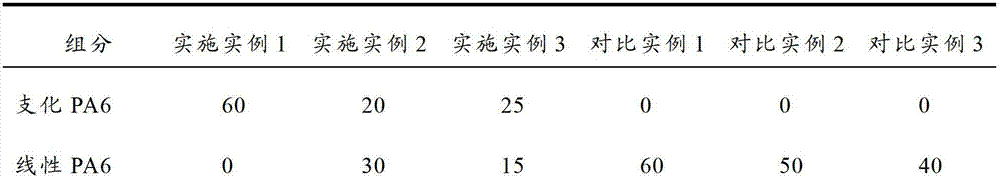

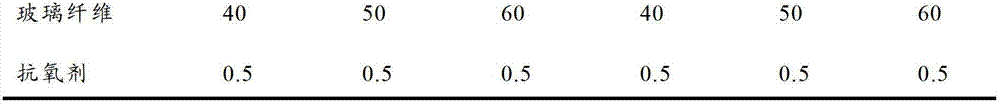

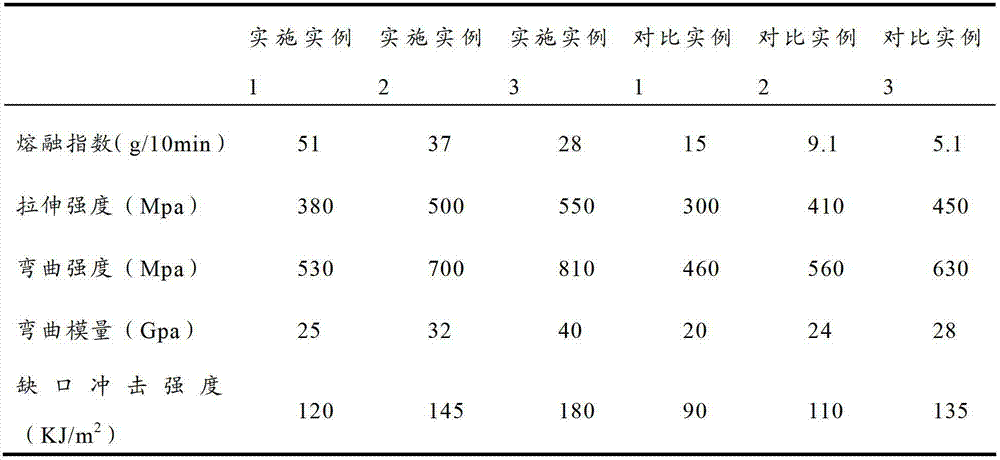

Examples

preparation example Construction

[0032] So, the present invention provides a kind of preparation method of continuous glass fiber / nylon flat belt, comprising:

[0033] Melting and kneading the nylon resin antioxidant to obtain a melt;

[0034] The melt and continuous glass fiber are extruded through a die head, drawn, pressed and wound to obtain a continuous glass fiber reinforced nylon flat belt.

[0035] The continuous glass fiber reinforced nylon flat belt is braided to obtain a continuous glass fiber reinforced nylon sheet.

[0036] The continuous glass fiber reinforced nylon sheet is laminated, heated and molded to obtain a continuous glass fiber reinforced nylon composite sheet.

[0037] According to the present invention, the melting temperature of the nylon resin is 240-260°C, and a twin-screw extruder is used for melting and kneading. The flat tape is braided into a thin plate, and then the thin plates are stacked and hot-pressed at 200-250°C to obtain a composite plate.

[0038] The continuous gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com