Catalytic cracking method for processing heavy oil, and apparatus thereof

A catalytic cracking unit and catalytic cracking technology, which are used in the petroleum industry, processing hydrocarbon oil, etc., to achieve the effect of long residence time and lower temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

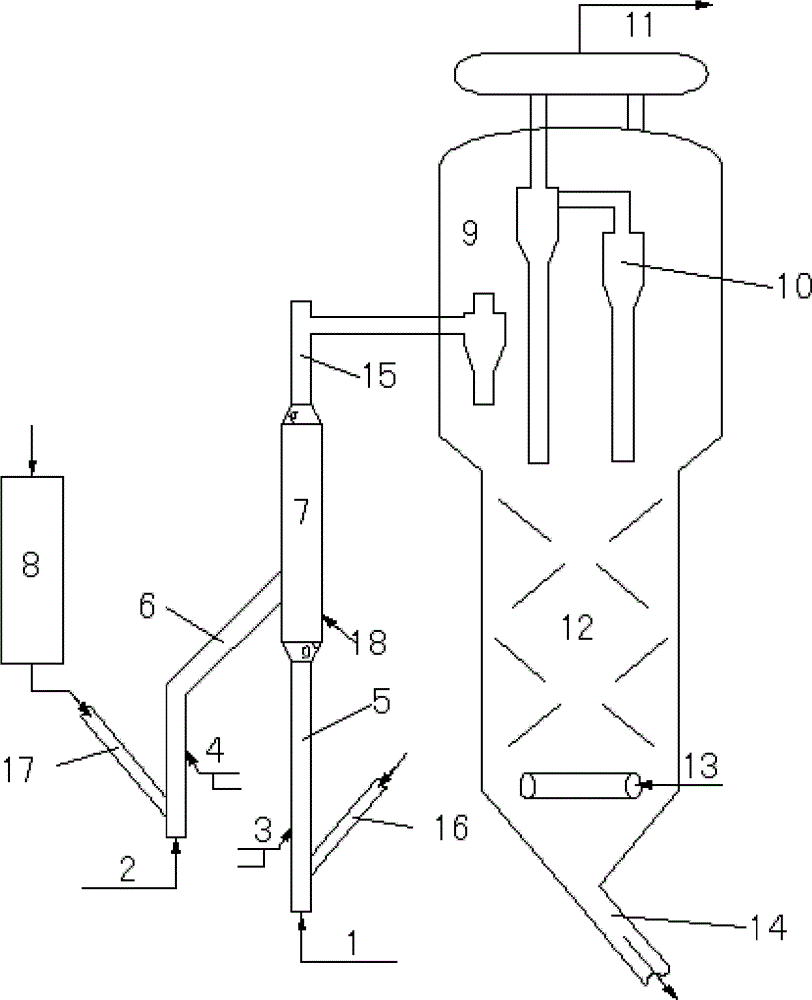

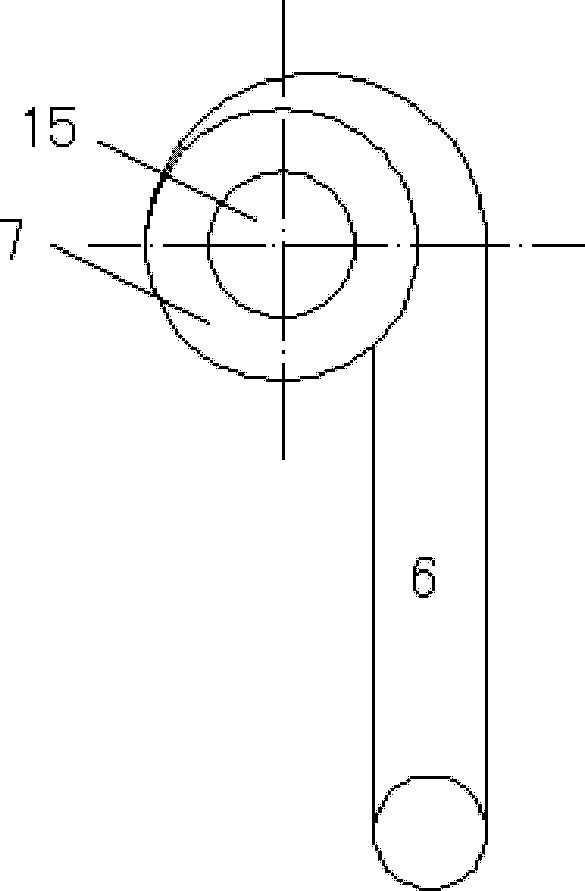

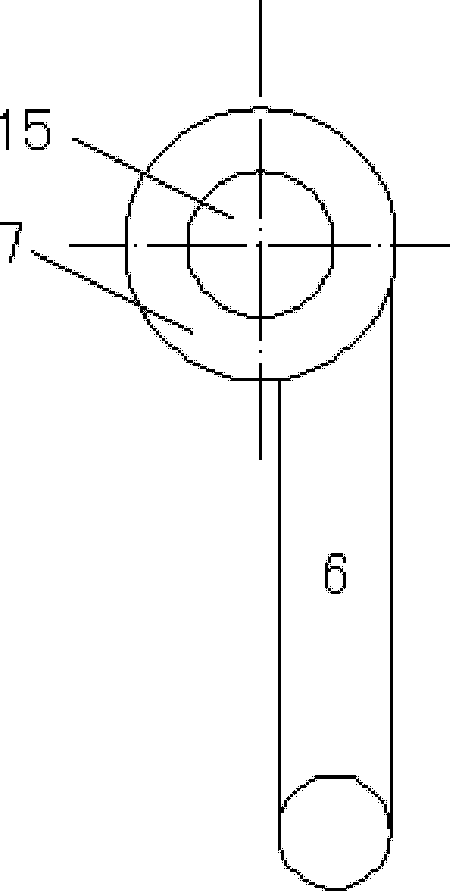

[0025] The main and auxiliary riser top view of the present invention can adopt figure 2 or image 3 form, this embodiment adopts figure 2 forms; riser catalytic devices for processing heavy oil such as figure 1 As shown, it is composed of main riser reactor, auxiliary riser reactor, gas-solid separation system and regeneration device; the main riser reactor is located next to the regeneration device, which is a riser with variable diameter, and the middle part of the main riser reactor is Expanded diameter riser 7, the upper riser 15 of the main riser is an outlet section that is radially equal to or reduced in diameter with the lower riser of the main riser, and communicates with the settler 9 of the gas-solid separation system, and the lower riser 5. There are lifting steam inlet a1, low-quality heavy oil inlet 3 and regeneration inclined pipe a16. The diameter-expanding riser 7 is at any position between 20% and 95% of the height of the main riser. 20 to 75%, the rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com