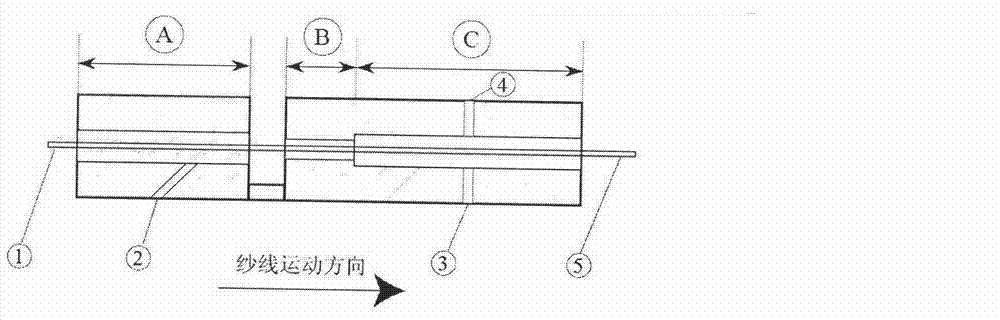

Composite nozzle device capable of reducing resultant yarn hairiness

A compound nozzle and yarn-forming technology, which is applied in the field of textile processing, can solve the problems of high fiber loss, large equipment investment, and difficulty in yarn spinning, and achieve the goals of improved anti-pilling performance, low equipment modification costs, and improved yarn quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

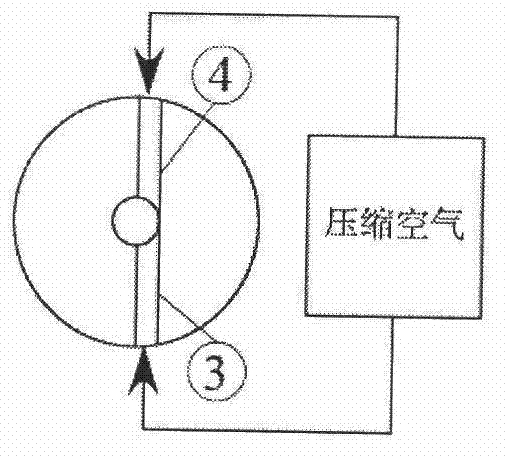

Method used

Image

Examples

Embodiment Construction

[0010] Raw material: pure cotton yarn with a basis weight of 4.52g / 10m. The spinning process conditions are: the pressure (gauge pressure) at the inlet of the vortex nozzle air passage is 0.05 MPa, and the spindle speed is 10000 rpm. Spinning Z-twisted pure cotton spun yarn with twist coefficient of 330 and fineness of 28tex.

[0011] Yarn performance testing is carried out in accordance with the national standard GB / T7243-1987 "Yarn Hairiness Measurement Method Projection Counting Method". Table 1 lists the performance comparison of ordinary ring-spun yarns and yarns processed with composite nozzles.

[0012] Table 1 Performance comparison of ordinary ring-spun yarn and yarn processed with composite nozzle

[0013] Yarn

<3mm hairiness index

≥3mm hairiness index

Ordinary ring spinning yarn

112.7

21

Install composite nozzle

152

0.6

[0014] It can be seen from Table 1 that after the installation of the composite nozzle: the hairiness below 3mm has increased, and the appro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com