Composite board door leaf and production method thereof

A production method and technology of composite panels, applied in the direction of doors, windows/doors, building components, etc., can solve the problems of end of service life, no treatment means, concrete residue, etc., achieve simple structure, good sound absorption, and increase ecological benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

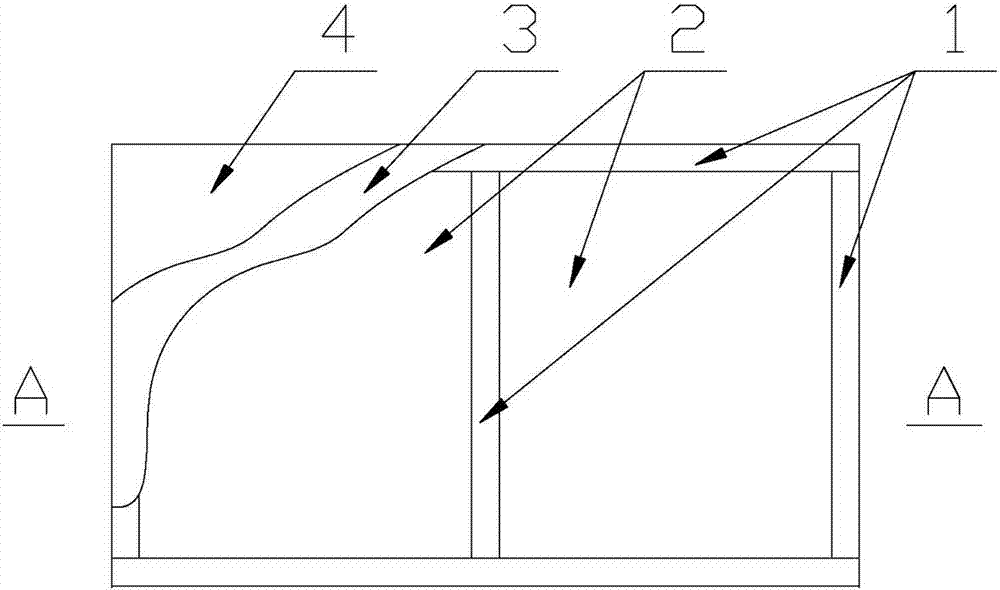

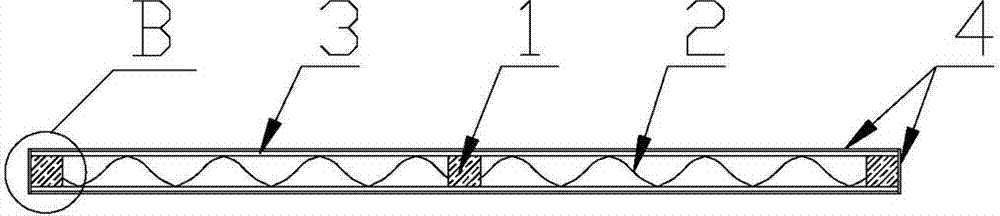

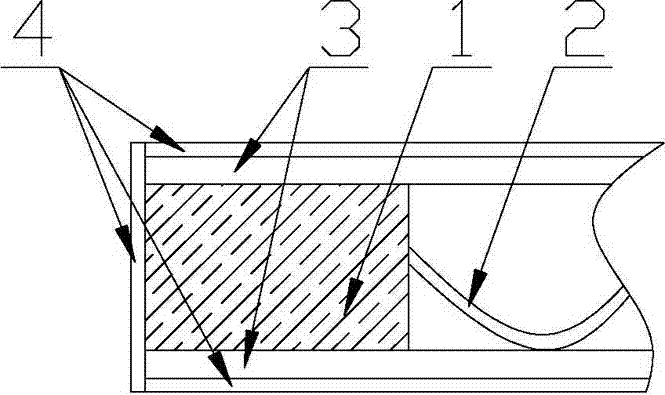

[0031] Depend on figure 1 , figure 2 , image 3 It can be seen that a composite panel door leaf includes a door frame 1, panels 3 are arranged on both sides of the door frame 1, and corrugated fillers are arranged between the panels 3 within the scope of the door frame 1.

[0032] In order to save resources and reduce costs in the present invention, the corrugated filler 2 is processed from waste bamboo plywood formwork or wood plywood formwork or bamboo wood plywood formwork.

[0033] In order to improve the strength and sound absorption of the present invention, the corrugated filler 2 has a corrugated spacing of 100 mm to 140 mm (140 mm in this embodiment).

[0034] For the sake of appearance in the present invention, a veneer layer 4 is provided on the panel 3 and around the door frame 1 .

[0035] What the veneer layer 4 of the present invention adopts is science and technology wood.

[0036] A method for producing a composite panel door leaf as described above, comp...

Embodiment 2

[0047] A composite board door leaf, the corrugated filler 2 has a corrugated spacing of 100mm-140mm (100mm in this embodiment).

[0048] A method for producing a composite panel door leaf as described above. When dipping in step (2), the block material is dipped in water-soluble phenolic resin glue with a concentration of 24% to 26% (26% in this embodiment) for 3 minutes to 5min (5min in this example), take out the glue and pre-dry it for 1h~3h (3h in this example), and stop drying when the moisture and volatile matter content is 10%~15% (15% in this example); Use a corrugated hot-pressing plate to heat-press the dried blocks. The temperature of the pressing plate is set at 135°C to 145°C (140°C in this example), and the pressure of the pressing plate is 3.5MPa to 5.0MPa (4.5MPa in this example). MPa), after taking it out, it will be cold-pressed and shaped (until the corrugated shape does not bounce back) to become the corrugated filler 2; in step (3), the temperature of the ...

Embodiment 3

[0051] A composite board door leaf, the corrugated filler 2 has a corrugated spacing of 100mm-140mm (120mm in this embodiment).

[0052] A method for producing a composite panel door leaf as described above. When dipping in step (2), the block material is dipped in water-soluble phenolic resin glue with a concentration of 24% to 26% (26% in this embodiment) for 3 minutes to 5min (3min in this example), take out the glue and pre-dry it for 1h to 3h (1h in this example), and then dry it in a drying kiln at a drying temperature of 75°C to 95°C (90°C in this example). The air flow rate is 1.0 m / s~1.8 m / s (1.8 m / s in this example), and the drying time is subject to the content of volatile matter meeting the requirements for use, that is, the content of moisture and volatile matter is 10%~15% (this example The embodiment is 10%) to stop drying; when setting the shape, use a corrugated hot-pressed plate to heat-press the dried block and set the temperature of the platen to 135°C to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com