Method for detecting tiny leakage of oil transmission pipeline

An oil pipeline and leak detection technology, applied in pipeline systems, pipe components, pipes/pipe joints/fittings, etc., can solve problems such as bulky volume, high detection cost, high risk of blockage or even damage to pipelines, and achieves high detection sensitivity, The effect of fast reception and fast transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

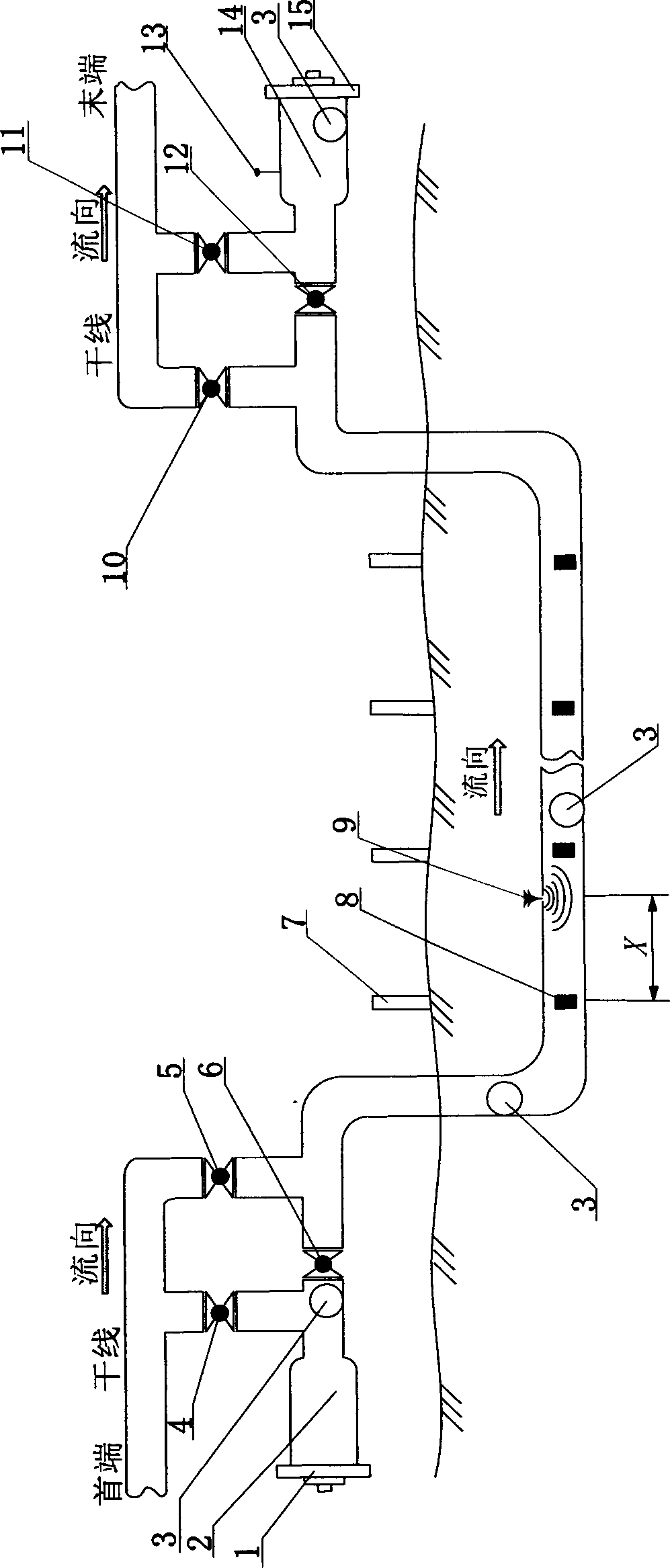

[0027] The method for detecting oil pipeline micro-leakage of the present invention will be further described below in conjunction with a field test and accompanying drawings.

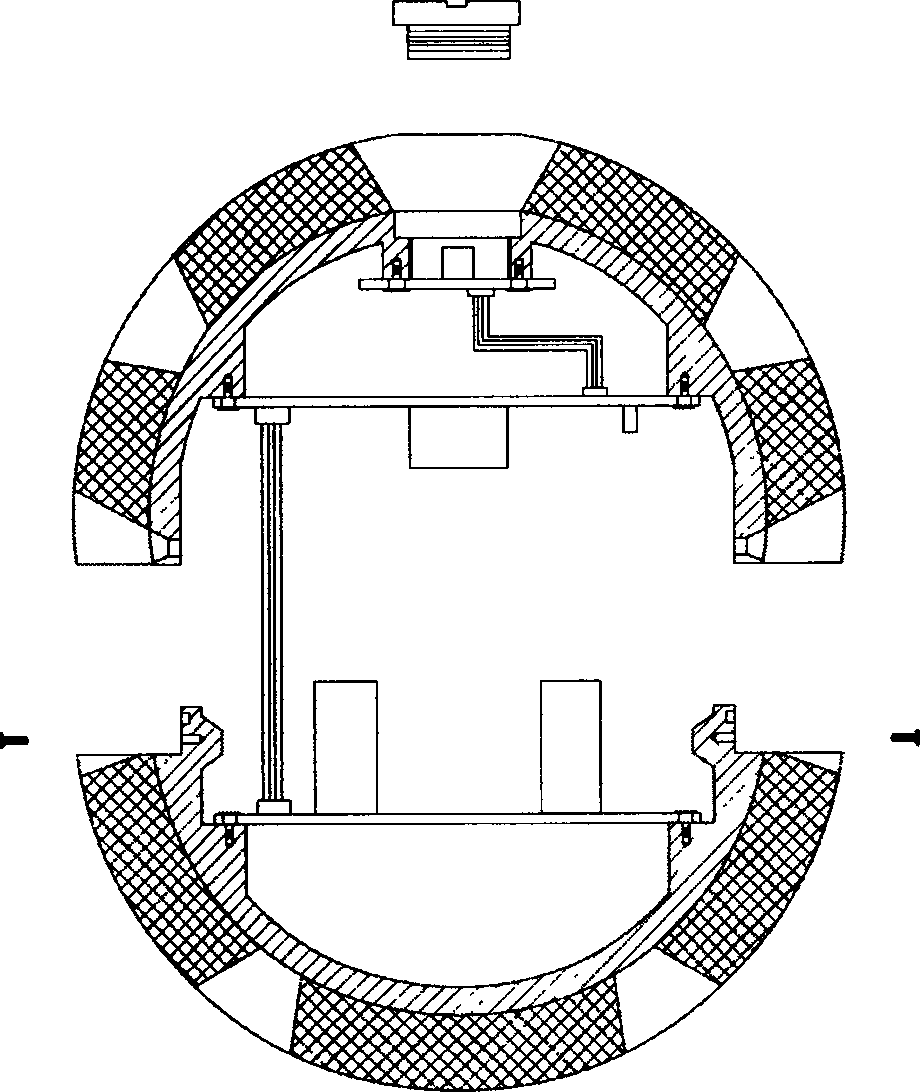

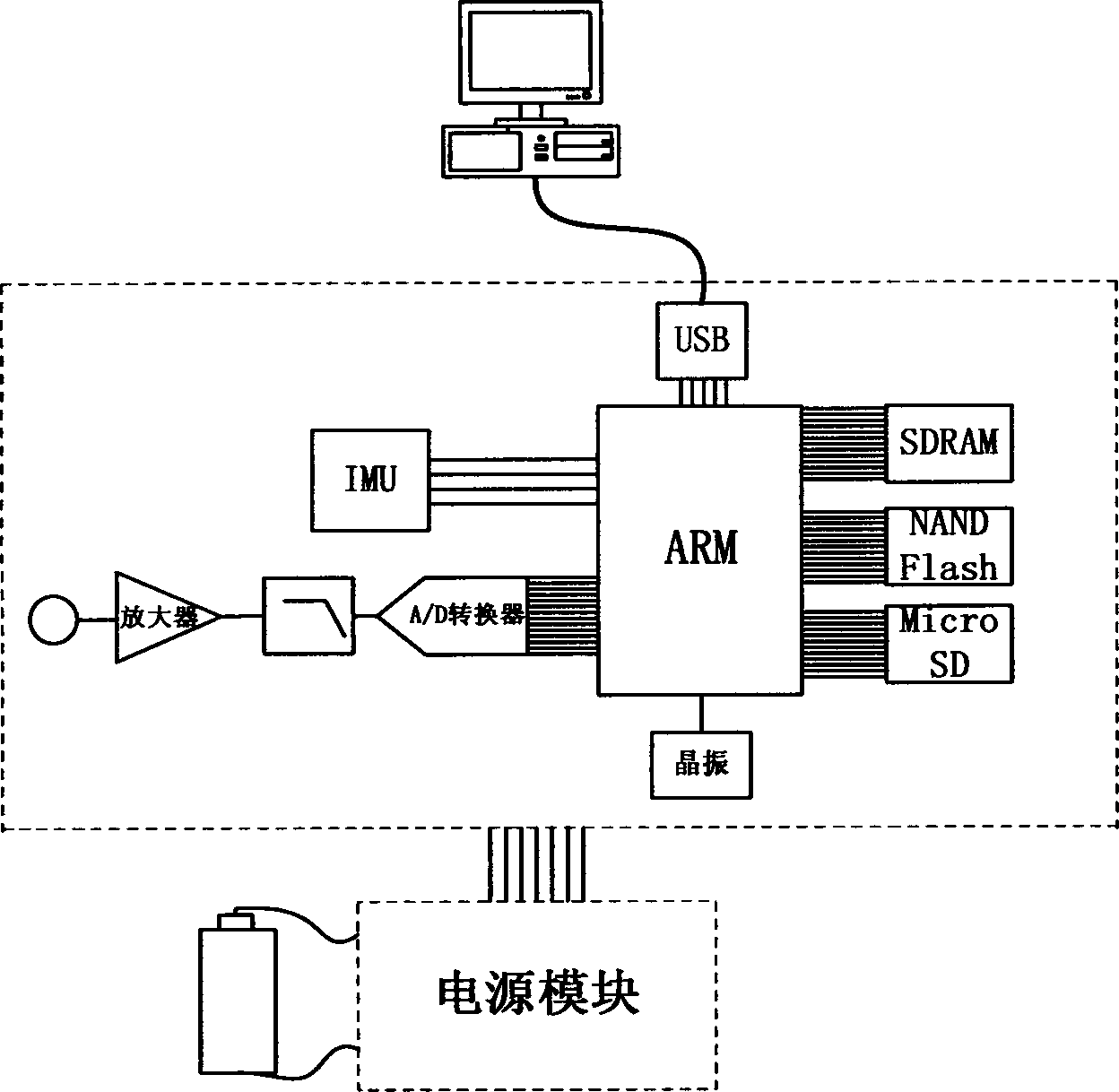

[0028]The present invention uses a spherical inner detector for detecting oil pipeline leakage as a detection device. The spherical inner detector includes a spherical pressure-bearing aluminum shell and an electronic device inside the aluminum shell. The outer diameter of the aluminum spherical shell is Φ100mm, and the wall thickness is 8mm. Pressure ≥ 5MPa; outside the spherical pressure-bearing aluminum shell is a polyurethane foam layer, the thickness of the foam layer is 30mm, and 8 tapered holes are opened on it; the interface circuit board, core circuit board and The power supply circuit board is provided with a Mini USB interface, a mechanical switch for controlling power-on and power-off, and a multi-color status indicator light on the interface circuit board; an ARM processor S3C2440 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com