Array substrate, manufacturing method of array substrate, and display device

An array substrate and substrate technology, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve problems such as alignment deviation, reduced transmittance, and light leakage, and achieve the effect of avoiding light leakage and enhancing adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

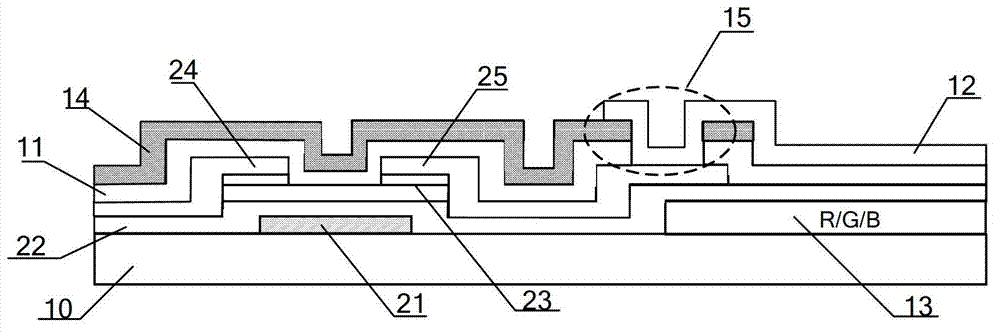

[0064] Such as figure 1 As shown, the embodiment of the present invention provides an array substrate suitable for TN products (TN mode), the array substrate includes: a substrate 10, a thin film transistor disposed on the substrate 10, a pixel electrode 12, and a passivation layer 11, the Thin film transistor comprises gate (Gate) 21, gate insulating layer (GI) 22, active layer (Active) 23, source (Source) 24 and drain electrode 25 (Drain); Passivation layer 11 covers thin film transistor, pixel electrode The device 12 is arranged above the passivation layer 11, and further includes: a patterned color resist layer 13 and a black matrix 14;

[0065] Wherein, the color resistance layer 13 is arranged between the substrate 10 and the gate insulating layer 22, and is distributed in the region corresponding to the pixel electrode 12; the black matrix 14 is arranged on the passivation layer 11, and is located in the region corresponding to the color resistance layer 13 outside the...

Embodiment 2

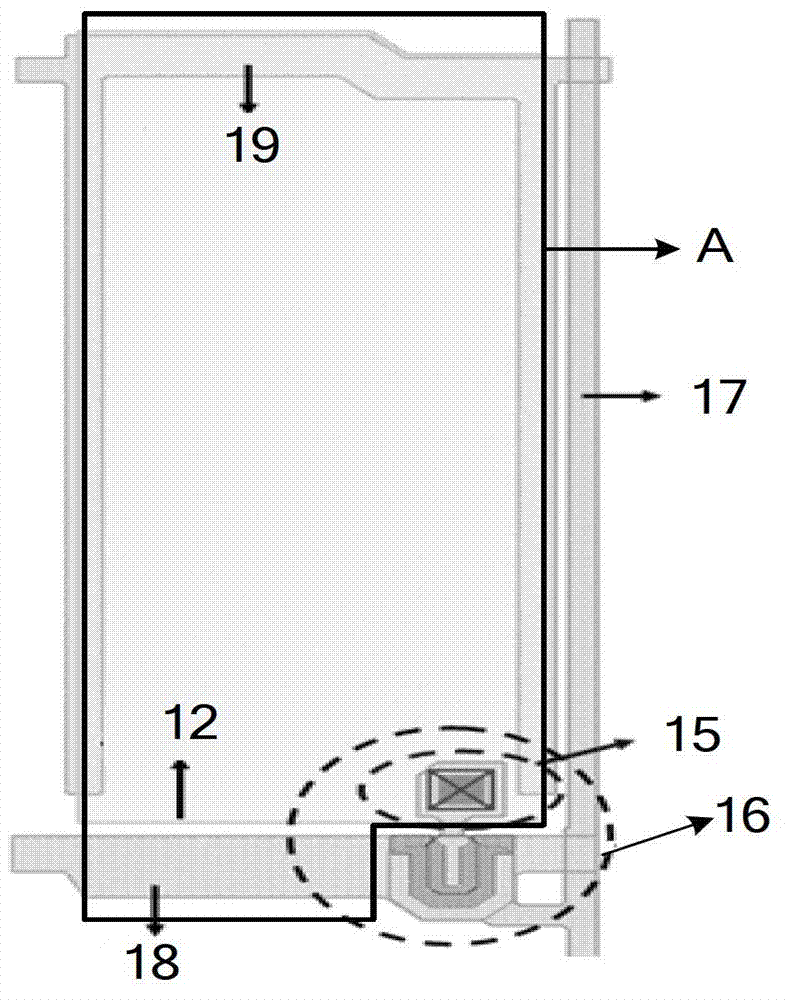

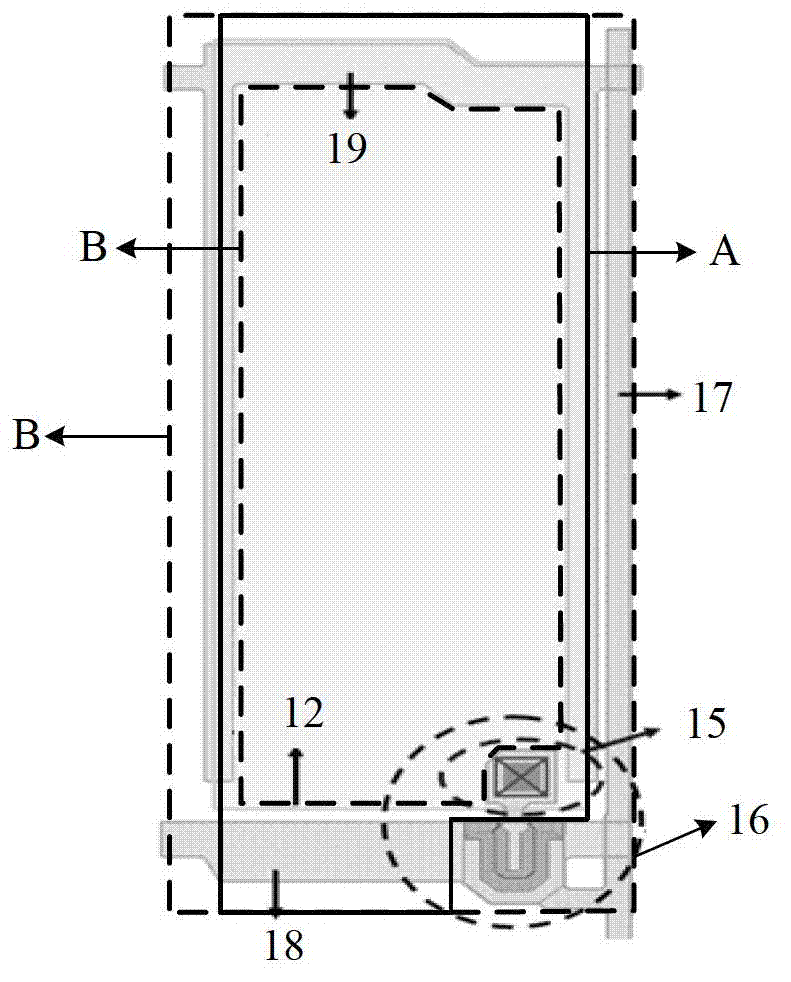

[0090] Embodiments of the present invention provide an array substrate suitable for ADS products (ADS mode), such as Figure 7 As shown, the difference between the array substrate and the array substrate described in Embodiment 1 is that it also includes: a common electrode 20 disposed between the substrate 10 and the color resist layer 13; in addition, because the ADS mode array substrate adopts a multi-dimensional electric field, Therefore, the pixel electrode 12 in this embodiment is in the shape of a slit, such as Figure 8 shown.

[0091] It should be noted that: the pixel electrode can be in the shape of a plate or a slit, and the same is true for the common electrode. The upper and lower order of the pixel electrode and the common electrode can be reversed, but the upper electrode must be in the shape of a slit, and the lower electrode must be in the shape of a plate. of.

[0092] Specifically, the array substrate includes: a substrate 10, a thin film transistor 16 di...

Embodiment 3

[0112] An embodiment of the present invention provides an array substrate suitable for HADS products (HADS mode), such as Figure 10 As shown, the difference from the array substrate described in Embodiment 1 is that the array substrate further includes:

[0113] The second passivation layer 26 covers the black matrix 14 and the pixel electrode 12;

[0114] The common electrode 20 is located above the second passivation layer 26 and disposed in a corresponding area of the pixel electrode 12 .

[0115] In addition, because the HADS mode array substrate uses a multi-dimensional electric field, the common electrode 20 on the upper layer is in the shape of a slit, such as Figure 11 shown.

[0116] The structure of the HADS mode array substrate in this embodiment is roughly similar to the ADS mode array substrate in Embodiment 2, the only difference is that the second passivation layer 26 is added, and the common electrode 20 is arranged on the second passivation layer 26 , w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com