Thin film transistor and array substrate

A technology of thin film transistors and array substrates, applied in the display field, can solve the problems of reducing the transmittance of a single board, and achieve the effect of improving the transmittance of a single board and reducing the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

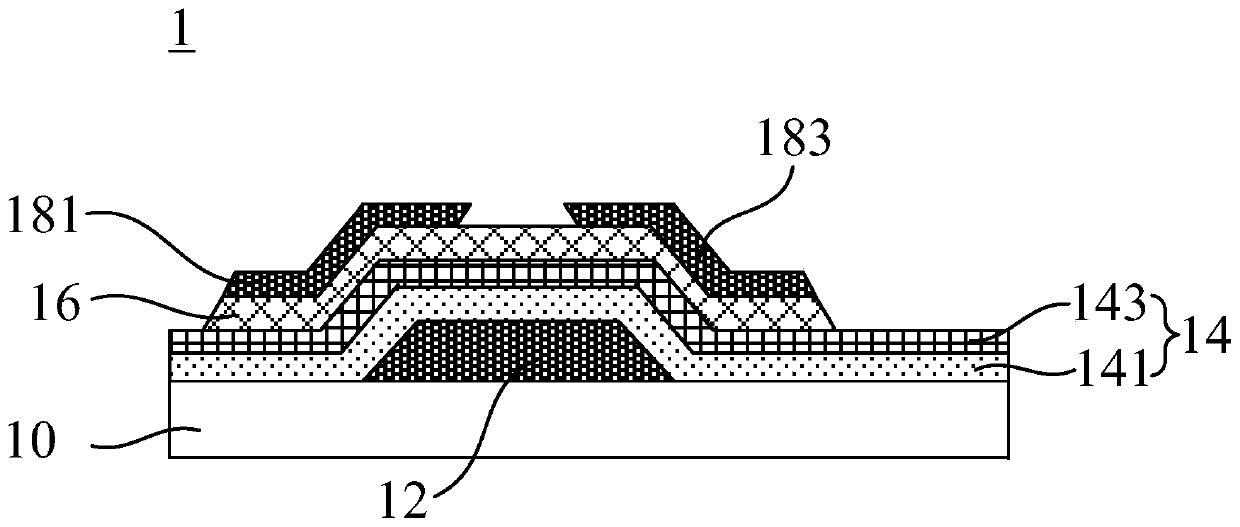

[0031] Example 1. Thin Film Transistor

[0032] In this embodiment, a thin film transistor 1 is provided, such as figure 2 As shown, the thin film transistor 1 is formed on a film-forming substrate 10, and includes: a gate 12 disposed on the film-forming substrate 10, a gate insulating layer 14 covering the gate 12, and disposed on the film-forming substrate 10. The semiconductor active layer 16 on the gate insulating layer 14 , and the source electrode 181 and the drain electrode 183 disposed on the semiconductor active layer 16 . The material of the semiconductor active layer 16 is indium gallium zinc oxide (IGZO).

[0033] Such as figure 2 As shown, the gate insulating layer 14 includes: a first gate insulating layer 141 covering the gate 12 , and a second gate insulating layer 143 disposed on the first gate insulating layer 141 . The thickness of the gate insulating layer 14 is less than or equal to 700 nm, and the thickness of the first gate insulating layer 141 is 8...

Embodiment 2

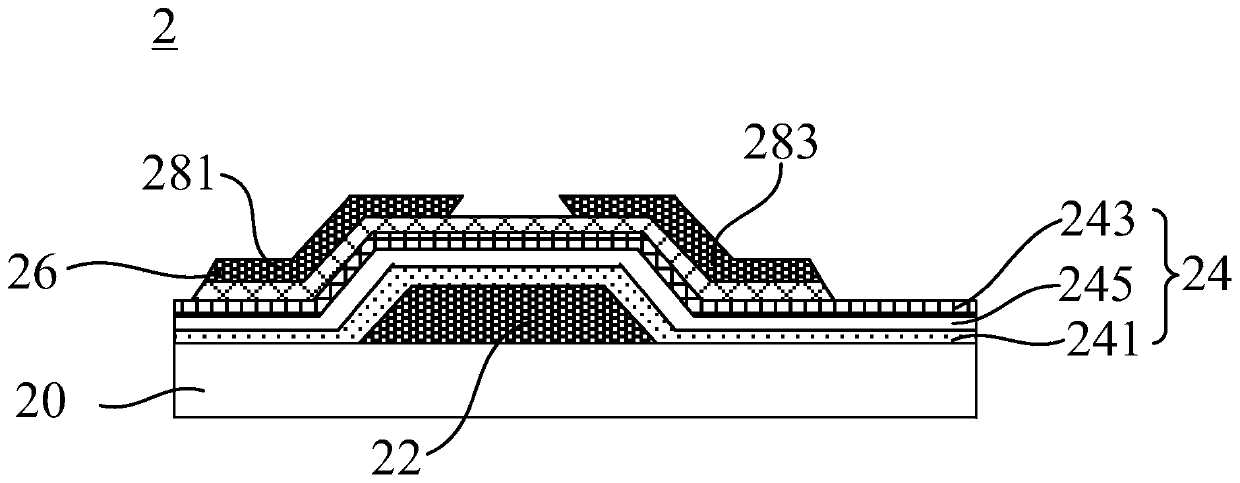

[0040] Example 2. Thin Film Transistor

[0041] In this embodiment, a thin film transistor 2 is provided, such as Figure 3A and Figure 3B As shown, the thin film transistor 2 is formed on a film-forming substrate 20, and includes: a gate 22 disposed on the film-forming substrate 20, a gate insulating layer 24 covering the gate 22, and disposed on the film-forming substrate 20. The semiconductor active layer 26 on the gate insulating layer 24 , and the source electrode 281 and the drain electrode 283 disposed on the semiconductor active layer 26 .

[0042] Different from the thin film transistor 1 in Embodiment 1, the gate insulating layer 24 of the thin film transistor 2 in this embodiment includes a first gate insulating layer 241, a second gate insulating layer 243 and a third gate insulating layer 245 . In this embodiment, the third gate insulating layer 245 may be as Figure 3A The shown arrangement is between the first gate insulating layer 241 and the second gate i...

Embodiment 3

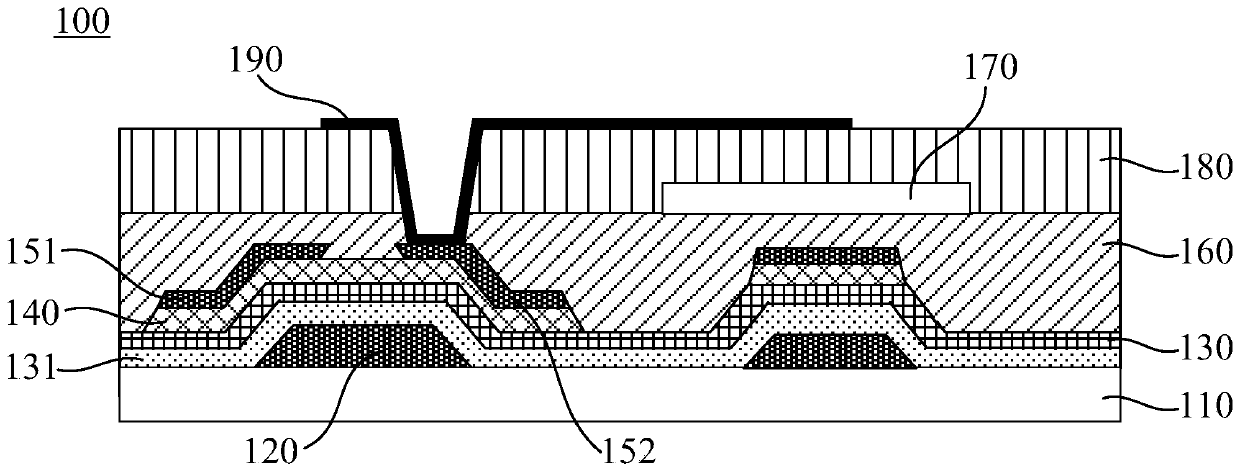

[0046] Example 3. Array substrate

[0047] In this embodiment, an array substrate 3 is provided, and the array substrate 3 includes a plurality of thin film transistors arranged in an array. Figure 4 Described is the thin film transistor structure in a pixel unit on the array substrate 3 . As an example, Figure 4 The array substrate 3 shown in the figure includes: a base substrate 30, a thin film transistor 1 disposed on the base substrate 30, a first passivation layer 32 covering the thin film transistor 1, disposed on the first A color resist layer 34 on a passivation layer, a second passivation layer 36 disposed on the color resist layer 34 , and a pixel electrode 38 disposed on the second passivation layer 36 . Such as Figure 4 As shown, the pixel electrode 38 is connected to the drain electrode 183 of the thin film transistor 1 through the first passivation layer 32 and the second passivation layer 36 .

[0048] Those skilled in the art can understand that the arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com