Built-in testing design method based on relevance model

A correlation model and test design technology, applied in the field of testability, can solve problems such as high product system complexity, design redundancy, and difficulty in assigning fault mode detection and isolation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

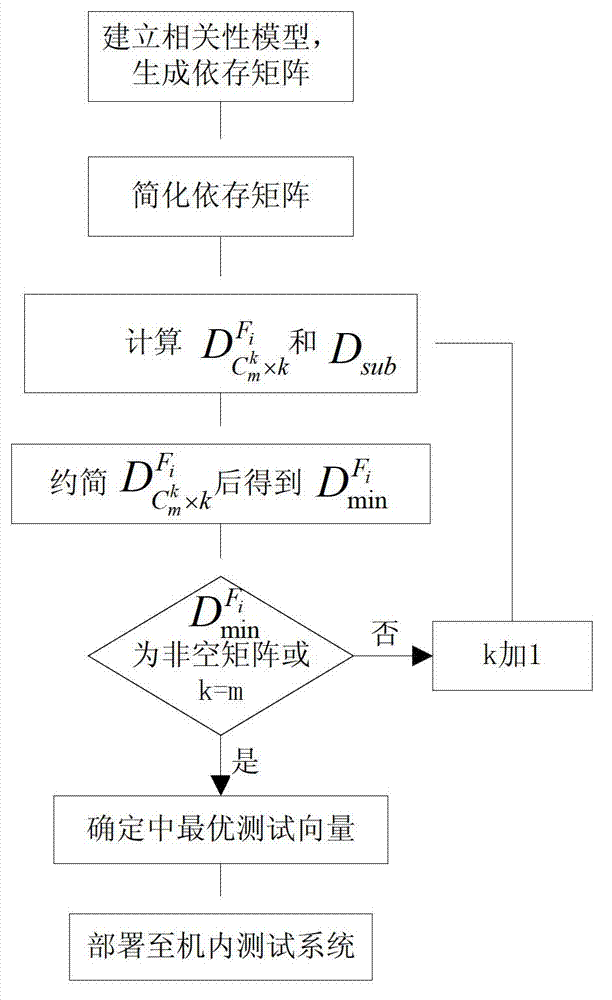

Method used

Image

Examples

Embodiment

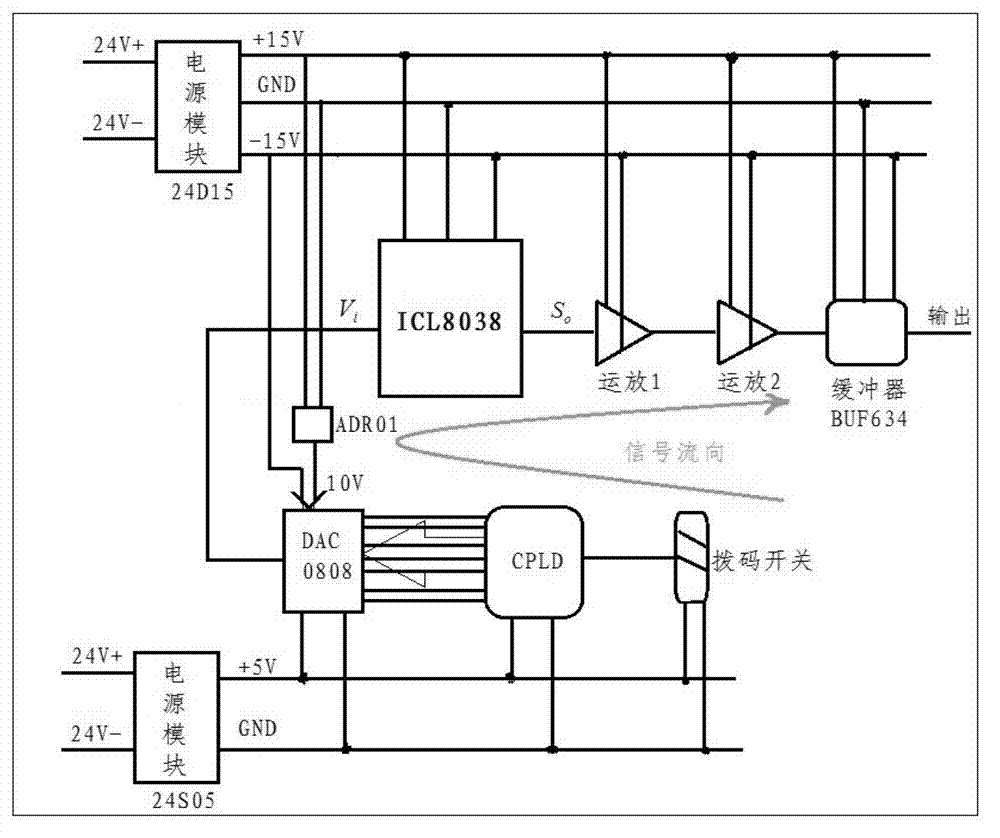

[0042] The object selected in this case is the resolver excitation circuit. The circuit is used to generate the sinusoidal signal required by the excitation winding of the resolver to provide excitation for the operation of the resolver, thereby realizing the detection requirements of the motor position in control systems such as aviation permanent magnet synchronous motors and brushless DC motors. The functional block diagram of the circuit is shown in figure 1 shown.

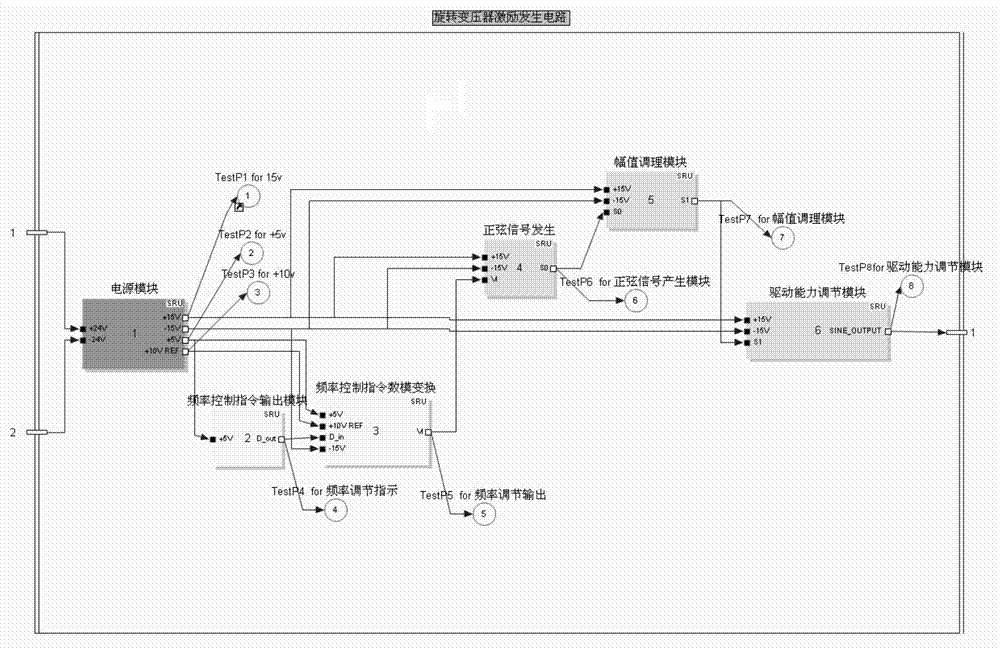

[0043] Based on the functional structure of the resolver excitation circuit, the testability modeling software is used to model the circuit, and the correlation model is obtained as follows: figure 2 As shown, the test model includes six functional modules including power supply module, sinusoidal signal generation, frequency control command digital-to-analog conversion, frequency control command output module, amplitude conditioning module, and drive capability adjustment module, and eight physical modules ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com