High-thermal-conductivity and high-heat-dissipation LED lamp

A technology of LED lamps and high heat dissipation, which is applied in the direction of semiconductor devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve the problems of low light efficiency, light loss, high heat generation, etc., to improve lighting brightness, improve efficiency, The effect of improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

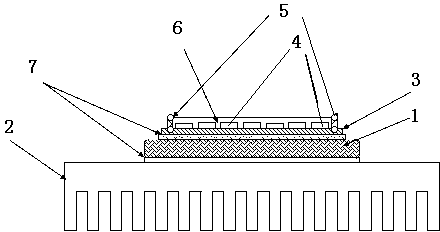

[0058] Combine below Figure 2 to Figure 18 , the present invention is further described:

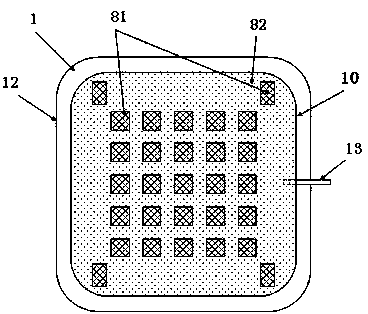

[0059] like figure 2 As shown, a first layer of film 81 corresponding to the fixing position of the LED chip and the fixing position of the chip support is pasted on the top of the cover plate 10 on the temperature equalizing plate 1 . Next, an insulating layer 82 is formed by coating a layer of insulating medium with high thermal conductivity on other areas of the cover plate 10 on the vapor chamber. The insulating layer 82 is used to form a circuit layer.

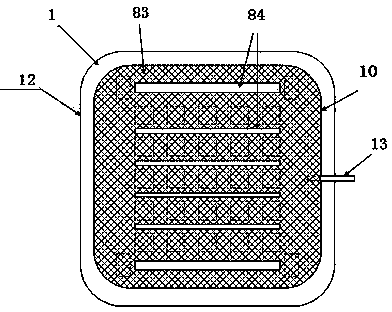

[0060] like image 3 shown, followed by figure 2 A second layer of film 83 is then pasted on the surface. The circuit reserved position is exposed on the second layer of film 83, which is used as a circuit conduction contact when the subsequent LED chips are packaged.

[0061] Next, a layer of copper is sputtered on the surface, and finally the second layer of film 83 and the first layer of film 81 are removed, that is, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com