Air battery case and injection molding method thereof

A technology of air battery and zinc-air battery, which is applied to battery components, circuits, electrical components, etc. It can solve the problems of air battery shells that cannot be bonded and easy to leak, and achieve scientific injection molding methods, prevent short circuits, and prolong service life. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

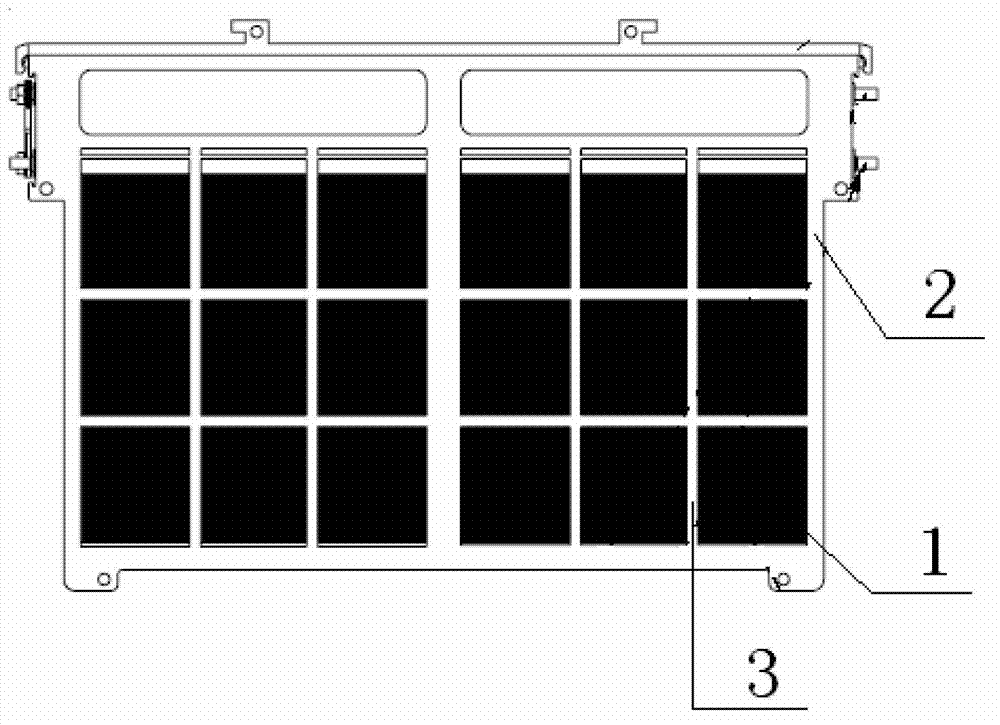

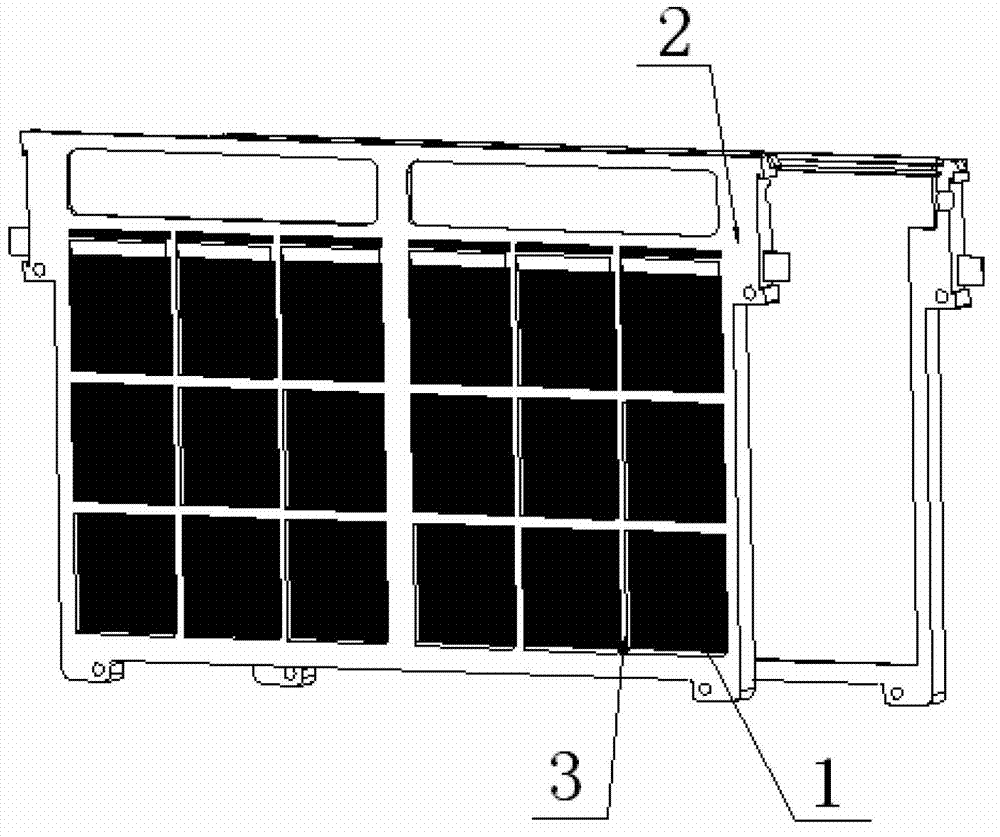

[0022] figure 1 It is a structural schematic diagram of the air battery case of the present invention; figure 2 It is a three-dimensional exploded view of the air battery case.

[0023] This embodiment discloses an air battery case, the structure of which is as follows figure 1 with figure 2 As shown, the air battery casing has a thickness of 1.0 cm, and includes a casing formed by welding two single-piece casings with a set accommodating space for placing a zinc negative electrode. The monolithic housing is rectangular and has a thickness of 2 mm. The monolithic case is a random copolymerized polypropylene case 2 wrapped around the positive air electrode 1, and each monolithic case is covered with more than two pieces of positive air electrodes, and the monolithic case is located outside the positive air electrode 1. A reinforcing rib 3 forming a grid is provided, and the reinforcing rib 3 is also made of polypropylene material, and is integrally injection-molded with t...

Embodiment 2

[0025] The difference from Example 1 is that the air battery casing disclosed in this embodiment has a thickness of 6.0 cm, and includes a casing with a set accommodation space formed by welding two single-piece shells. The set accommodation space is used for to place the zinc anode. The thickness of the monolithic casing is 9 mm, and the monolithic casing is a polyethylene casing wrapped around the positive electrode of the air. Without affecting the load-bearing strength of the air battery case, an inward depression is also provided at the place where the single-piece case is away from the positive electrode of the air (such as near the opening of the air battery case), which reduces the injection molding material and reduces the weight of the zinc battery case. body weight. The case of the air battery of this embodiment was tested for water, and no liquid leakage occurred.

[0026] In addition, ABS can also be used instead of polyethylene as the injection molding material...

Embodiment 3

[0028] This embodiment discloses the injection molding method of the air battery case described in Embodiment 1, which specifically includes the following steps:

[0029] (1) Use a high-pressure hot-melt injection molding machine to make random copolymerized polypropylene at a rate of 150t / cm 2 The pressure is injected into the mold with the air electrode through the injection head, the water is cooled to room temperature and shaped, and then the mold is released to obtain a single-piece shell;

[0030] (2) Ultrasonic welding is performed on the edges of the two opposite single-piece shells. The ultrasonic welding time is 50s, and the welding temperature is 150°C, so that the edges of the two battery shells are fully fused to obtain a battery with a set capacity. The shell of the space, that is, the air battery shell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com