Nanoflotation

A flotation box and foam flotation technology, applied in the field of nano-flotation, can solve the problems of rough membrane and membrane interval and the effect of pre-coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

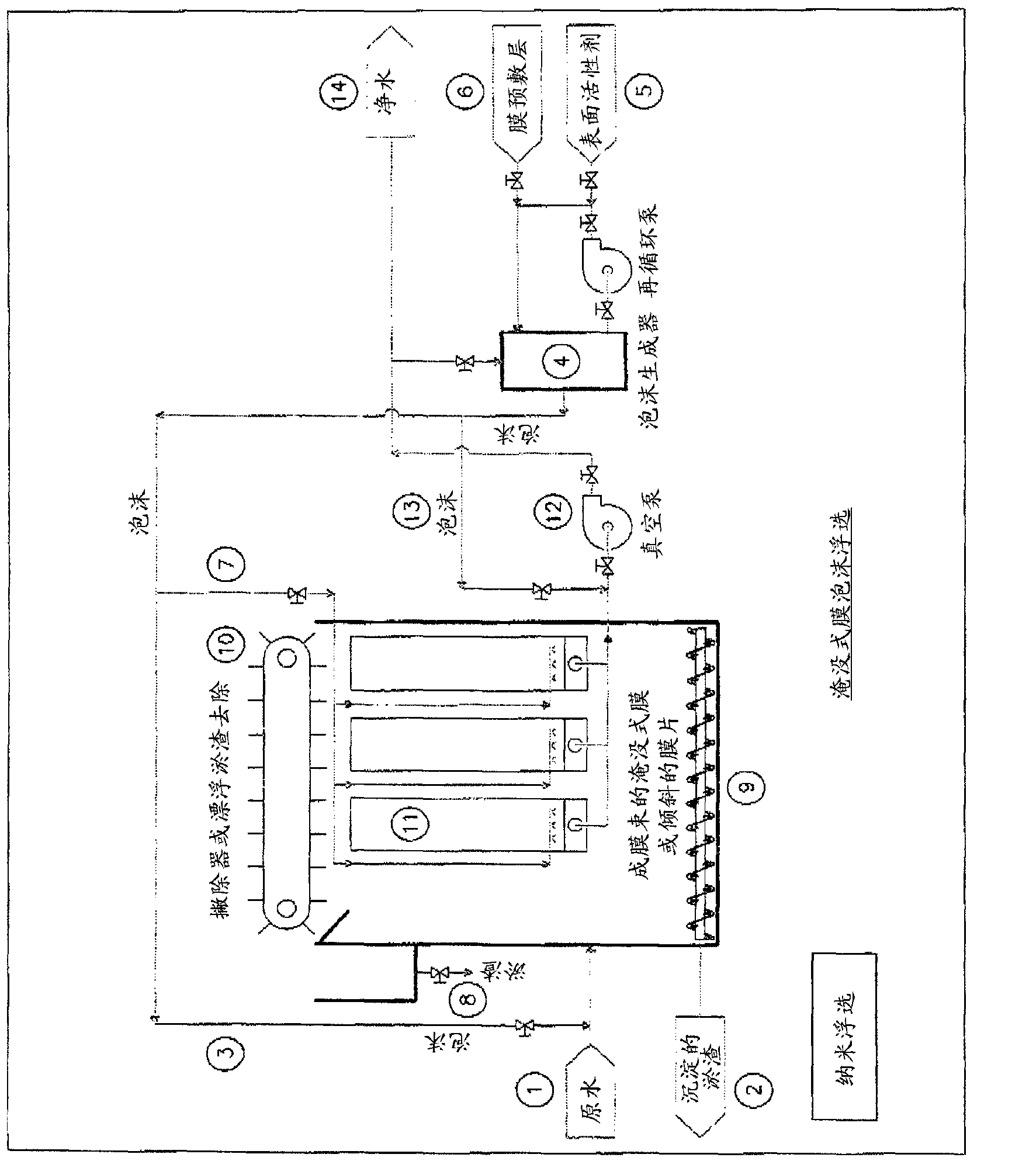

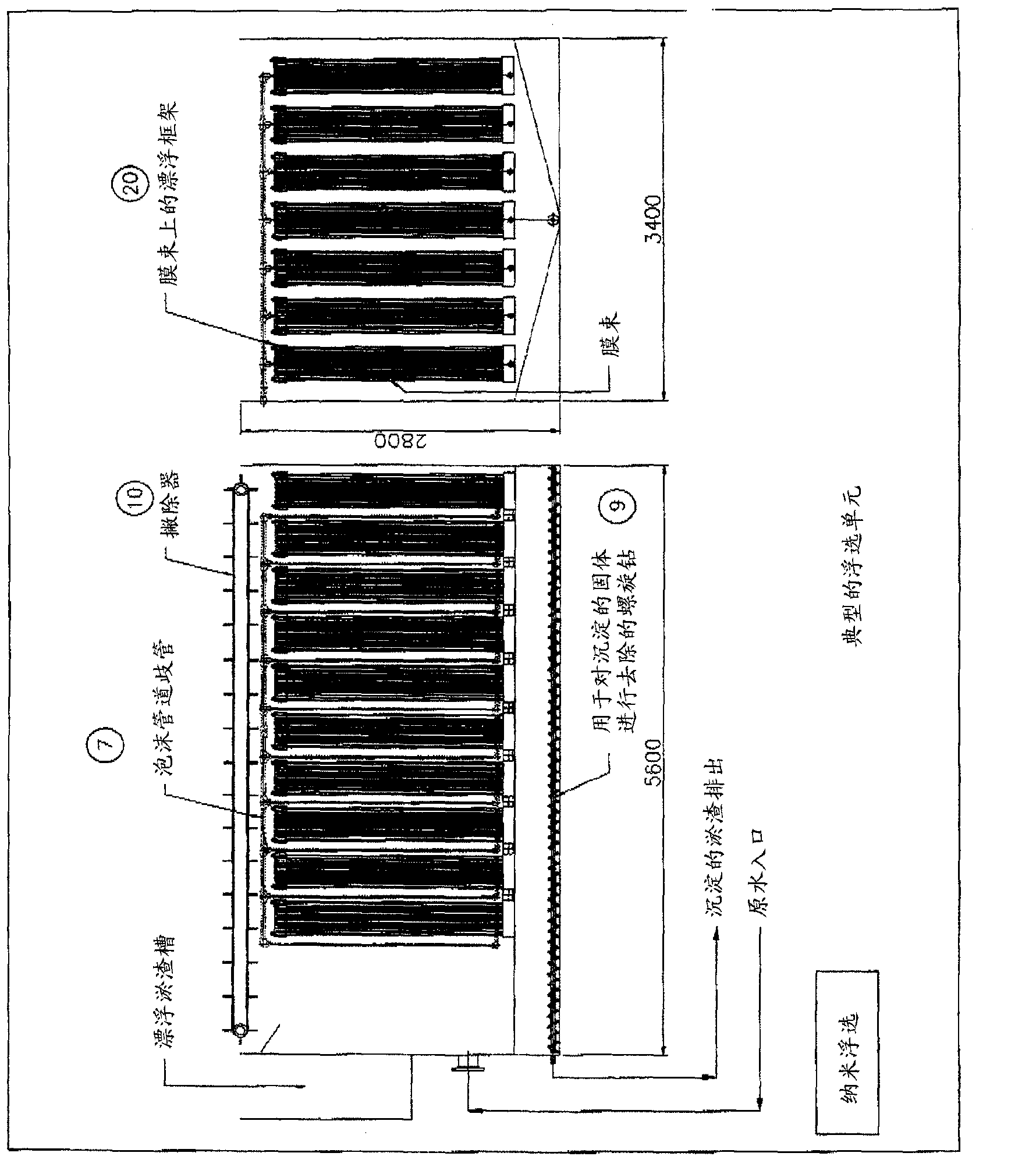

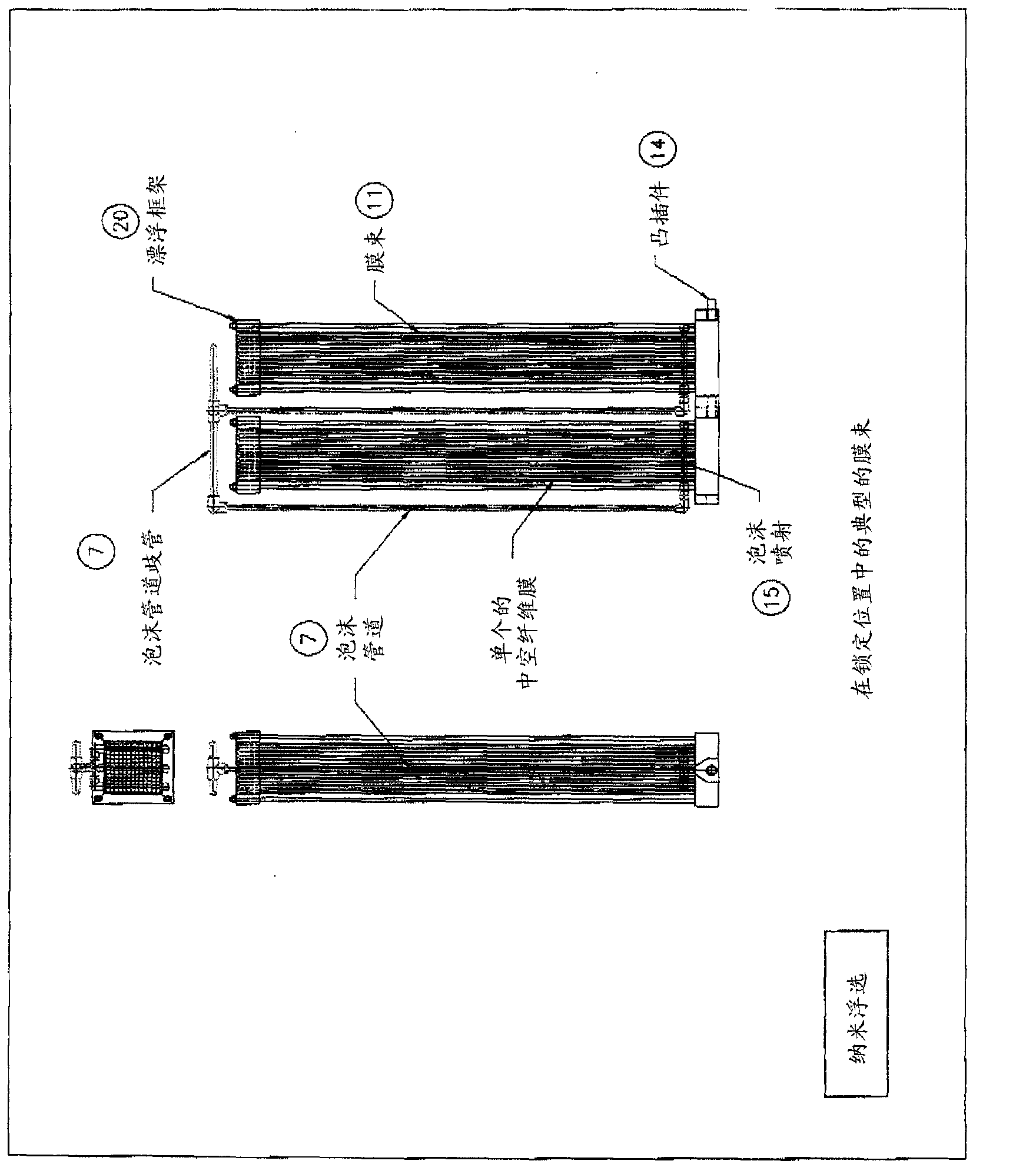

[0025] Raw water or waste water or any liquid 1 requiring solids separation is conveyed to a flotation tank or flotation cell which has an area on the bottom 9 for the settled solids and an area on the top for With an area where the flotation solids are collected or a skim or floating layer 10, the flotation cell or flotation cell has means to remove solids from both the top and the bottom. The flotation tank / unit will comprise submerged membranes 11,23. Sludge is removed from the flotation tank / unit via the bottom of the tank / unit and / or the skimming collection tank 8 . Water or waste water or any liquid 1 with solids entering the flotation cell / tank has froth 3 added to the water or waste water or liquid 1 with solids. Foam is generated from a typical foam generator 4 . The foam is formed by using a foam 5-forming surfactant or the like. Foam is also added between the membrane fibers 16 or flat sheets 23 during normal filtration operation of the flotation cell / unit. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com