Variable diameter screw propeller

A propeller and variable technology, applied in the direction of propellers, aircraft parts, transportation and packaging, etc., can solve the problems of increasing the overall weight of the propeller and increasing the complexity of the propeller control system, so as to improve the adaptability of high and low altitude flight and increase the range of diameter change , Improve the effect of aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

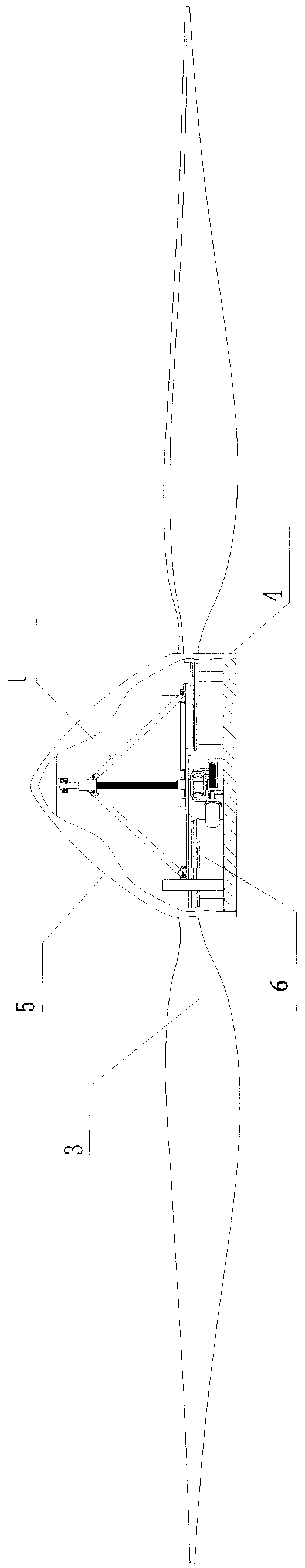

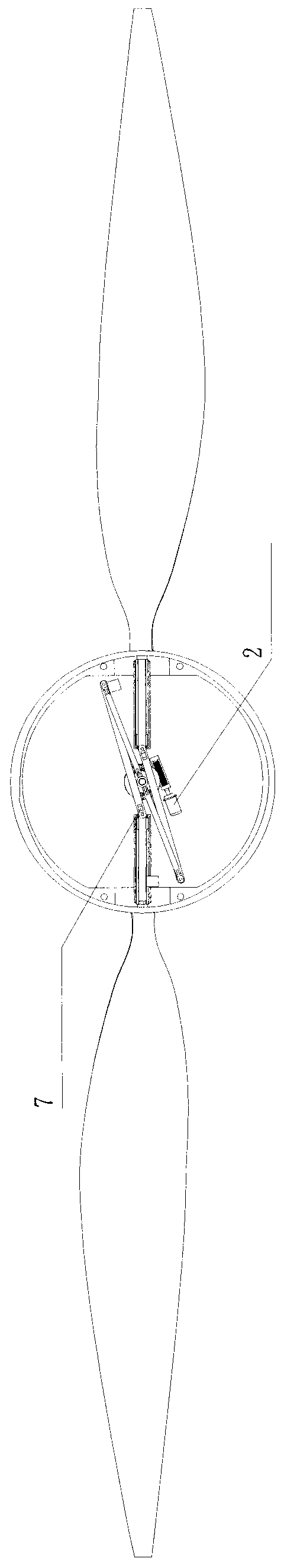

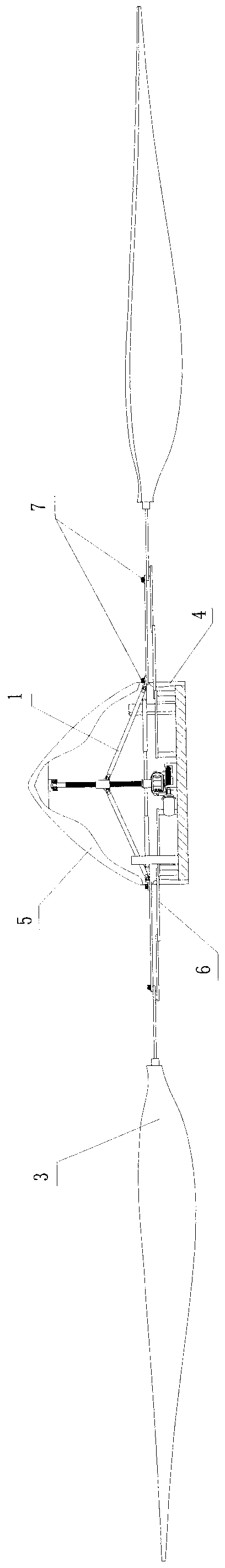

[0042] The mechanism in this example realizes the telescopic movement of the blade through two-dimensional motion (rotation and compression), so that the diameter of the propeller disk can vary by nearly two diameters of the hub. The specific structure is as follows:

[0043] Such as Figure 3A , 3B As shown, the linkage mechanism 1 of the present invention is mainly composed of four parts, the waist link 101 , the bottom link 102 , the push rod 103 and the guide rod 104 . Among them, the waist connecting rod 101 and the bottom connecting rod 102 constitute an isosceles triangle connecting rod mechanism, which plays the role of rotation deformation and compression deformation; and the push rod 103 and guide rod 104 constitute a sliding connecting rod mechanism, which plays a role of pushing and sliding guiding. role. The isosceles triangle connecting rod mechanism is installed on the lead screw 210 with the central axis of the spinner cap 5 as the rotating shaft through the...

Embodiment 2

[0056] Of course, the structure of the present invention can only be realized by adopting the rotation method in Embodiment 1 when the diameter of the propeller does not require much change. At this time, the structure has little change compared with Example 1, and the difference is only reflected in the drive mechanism and the connecting rod mechanism. The specific structure is described as follows:

[0057] Drive mechanism 2 comprises motor 201, worm screw 202, worm screw fixed seat 203, worm wheel 204, worm wheel fixed shaft 205, differential gear 206, upper end bevel gear 208, rotating arm 209, rotating shaft and gear support seat 212; Motor 201 is fixedly installed on On the inner bottom surface of the propeller hub 4, the output shaft of the motor 201 is connected to the worm 202, and the two ends of the worm 202 are installed on the worm fixing seat 203, and the worm fixing seat 203 is installed on the inner bottom surface of the propeller hub 4; the worm wheel 204 is in...

Embodiment 3

[0060] Other possible institutional implementations:

[0061] In the above-mentioned two embodiments, the lock release mechanism adopts the armature and the spring to control the expansion and contraction of the pin, so as not to add an extra power source to the mechanism. Of course, if the structure permits, the expansion and contraction of the pin can be realized by means of a motor controlling the cam, or the expansion and contraction of the pin can be achieved by using the motor to control the rotation of the lead screw through the nut matched with the lead screw.

[0062] The motor, worm gear and worm gear in the driving mechanism in the above two embodiments can adopt motor, bevel gear meshing and other modes, as long as the output of the motor can drive the rotation of the differential gear.

[0063] As a further improvement, the number, diameter, and width of propeller blades can be comprehensively improved according to the characteristics of high and low altitude atmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com