Tire bead wire tempering device and method

A technology of tempering device and bead wire, which is applied to heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problems of poor control accuracy, high labor intensity, and affecting the performance of product cleaning rods, so as to improve efficiency, performance, and control high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

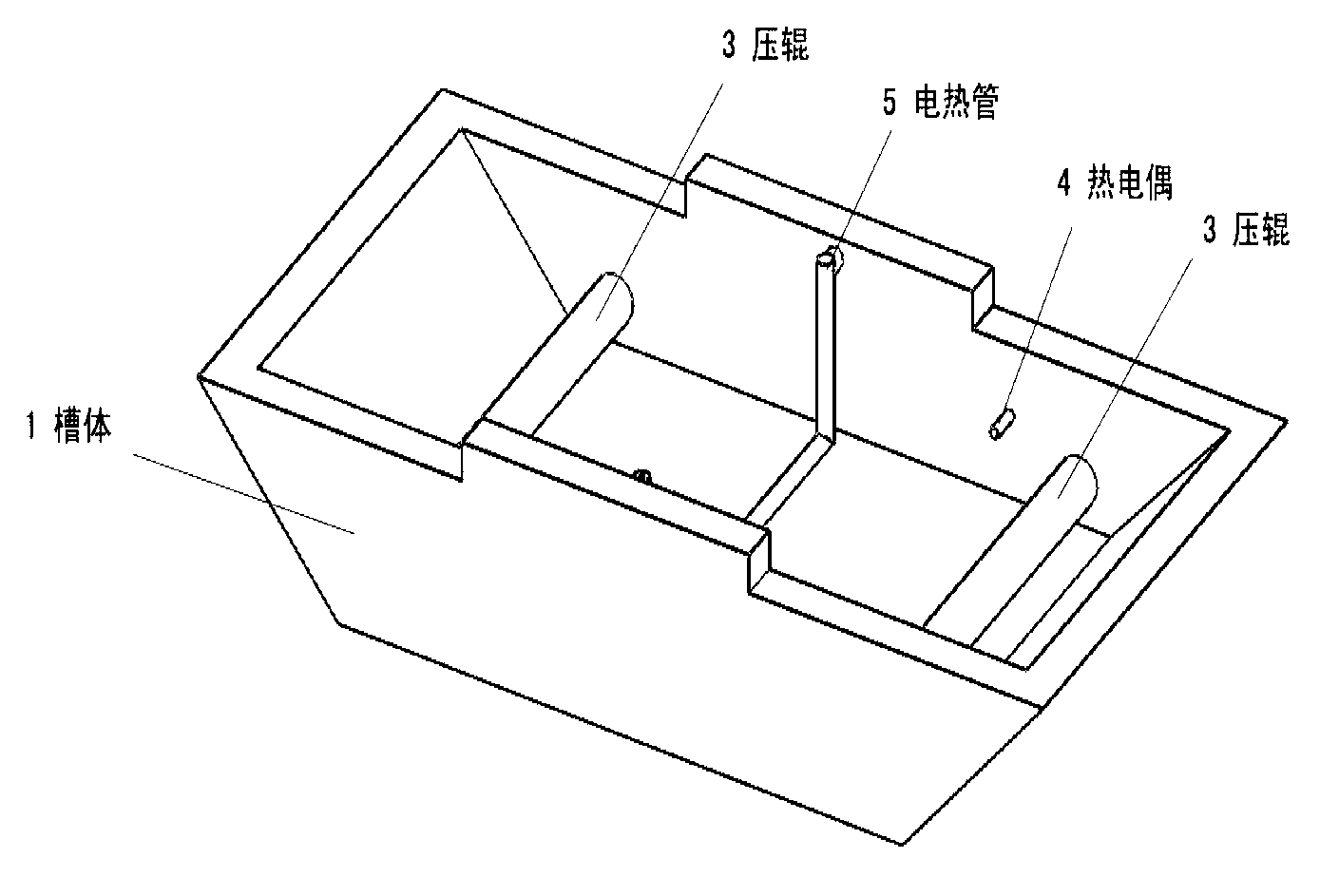

[0028] Such as figure 1 As shown, this patent is realized in this way: the steel wire 2 enters the lead liquid in the quenching tank body 1, and passes through a group of pressing rollers 3, and then completes the tempering operation to the bead steel wire. The tempering device is divided into three zones, and each zone has an independent thermocouple 4 for temperature measurement. By transmitting the collected temperature signal to the programmable controller, the programmable controller drives the electric heating tube 5 to complete the tempering according to the set parameters. Warming of the medium.

[0029] After the steel wire 2 is treated by the tempering device, the strength dispersion of the steel wire is less than 20 mpa, and the yield strength specific dispersion of the steel wire can be controlled within 1%.

Embodiment 2

[0031] On the basis of the above examples, if figure 1 As shown, a bead wire tempering device includes a trapezoidal inner hollow tank body 1, wherein the tank body 1 is stainless steel with heat-insulating asbestos in the middle of a double-layer structure, that is, the material is stainless steel, and the middle layer is an insulation layer. Thermal insulation asbestos, the outer layer is also made of stainless steel, with a trapezoidal design, which can reduce lead liquid by 20%, saving costs. In addition, after the tempering treatment is completed, when the steel wire leaves the tank body 1, the trapezoidal structure design is adopted, so that the residual lead liquid on the surface of the steel wire can slide down naturally, so as not to adhere to the surface of the steel wire and affect the product quality. A pressure roller 3 is arranged symmetrically at both ends of the tank body 1 , and lead liquid is arranged in the tank body 1 .

[0032] Preferably, the pressure ro...

Embodiment 3

[0038] On the basis of the above embodiments, the present invention provides a bead wire tempering method, which includes the following steps:

[0039] A: Lead liquid is placed in the hollow tank inside the trapezoid;

[0040] B: The thermocouple detects the temperature and transmits the collected temperature signal to the programmable controller;

[0041] C: The programmable controller drives the electric heating tube to complete the heating of the tempering medium;

[0042] D: The steel wire passes through the bottom of the pressure rollers installed at both ends of the tank body to complete tempering.

[0043] The method, wherein, step B1 is also performed after performing step B: when the temperature value detected by the thermocouple is lower than the set temperature value, the programmable controller gives a heating drive signal, and when the detected temperature reaches the set temperature value When the value is set, the programmable controller will give a drive sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com