A fully distributed optical fiber strain and vibration sensing method and device based on orthogonal polarization state switching

A fully distributed, orthogonal polarization technology, applied in the direction of optical devices, measuring devices, instruments, etc., can solve problems such as difficulty in maintaining constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

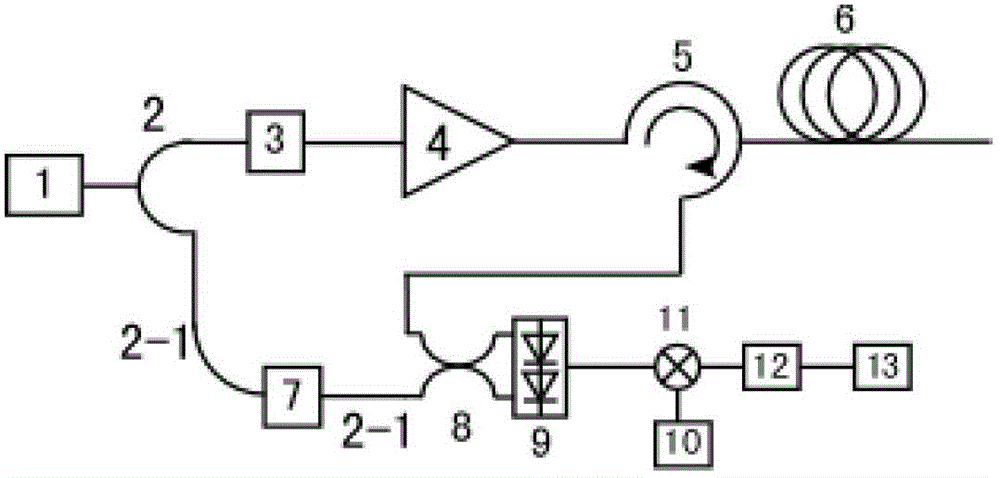

[0019] Such as figure 1 As shown, a fully distributed optical fiber strain and vibration sensing device structure based on orthogonal polarization switching, including laser (1), polarization maintaining coupler (2), polarization maintaining fiber (2-1), pulse modulation Module (3), optical amplifier (4), circulator (5), sensing fiber (6), polarization switching device (7), coupler (8), balanced photodetector (9), microwave source (10 ), a mixer (11), a bandpass filter (12), and a signal acquisition and processing unit (13). The continuous light output by the laser (1) is divided into two paths after passing through the polarization maintaining coupler (2): all the connecting fibers in the first path output by the polarization maintaining coupler are polarization maintaining fibers, and the light waves in it are used as reference light , after passing through the polarization state switching device (7), it is input to the first input end of the coupler (8); the polarization s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com