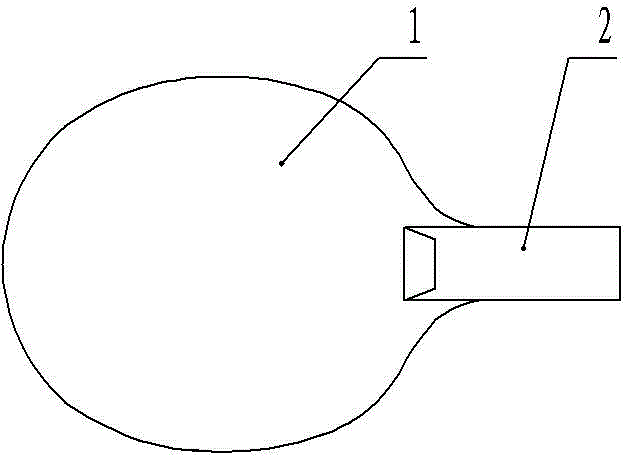

Bottom plate of bamboo and wood table tennis bat and manufacturing method thereof

A table tennis racket, table tennis technology, applied in rackets, wood layer products, chemical instruments and methods, etc., can solve the problem of high market price of carbon fiber balls, poor elasticity, reduced hitting strength, and unstable ball hitting. And other problems, to achieve the effect of strong rotation, good ball control, durable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

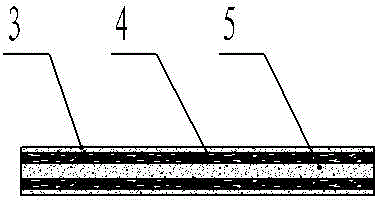

[0035] In Example 1, the thickness of the core plate layer 5 is 3.4 mm, the thickness of the plywood layer 4 is 0.8 mm, and the thickness of the outer plate layer 3 is 0.4 mm.

Embodiment 2

[0036] In Example 2, the thickness of the core plate layer 5 is 3.8 mm, the thickness of the plywood layer 4 is 0.7 mm, and the thickness of the outer plate layer 3 is 0.3 mm.

[0037] The manufacturing method of the bamboo and wood table tennis soleplate comprises the following steps:

[0038] a. Material selection and blanking:

[0039] ⑴. Select nanzhu that has grown for 4 to 6 years, bamboo with a thickness of 8mm to 12mm, and sawn into a bamboo tube according to the length of 270mm;

[0040] ⑵. Select wood with a diameter of 100mm to 200mm, and saw it into wood segments according to the length of 270mm;

[0041] b. Handling:

[0042] (1) Dilute the original solution of the anti-mold and moth-proof agent into a 1% aqueous solution, soak and cook the bamboo tube, and cook at a temperature of 100° C. for 4 hours to 5 hours;

[0043] (2) Dilute the wood softener stock solution into an aqueous solution of 5%-8%, and soak the wood segments for 24 hours to 48 hours;

[0044]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com