Continuous casting production line of rotary castings

A technology of casting production line and rotary shape, which is applied in the field of casting production line and continuous casting production line. It can solve the problems of affecting the quality of civilian rotary castings, the shape of finished products is inconsistent, and the quality of finished products is not uniform, so as to achieve friendly interface, uniform product processing shape, and production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

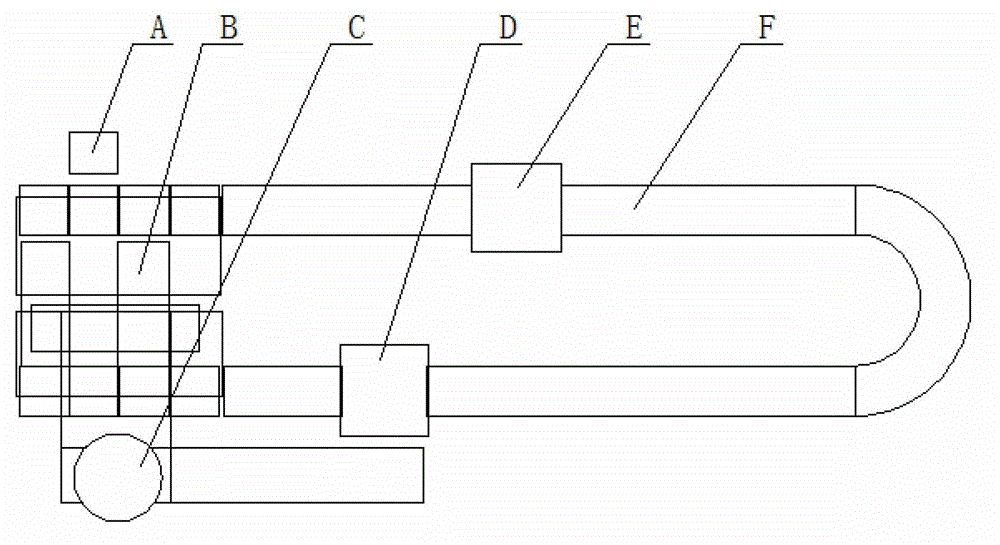

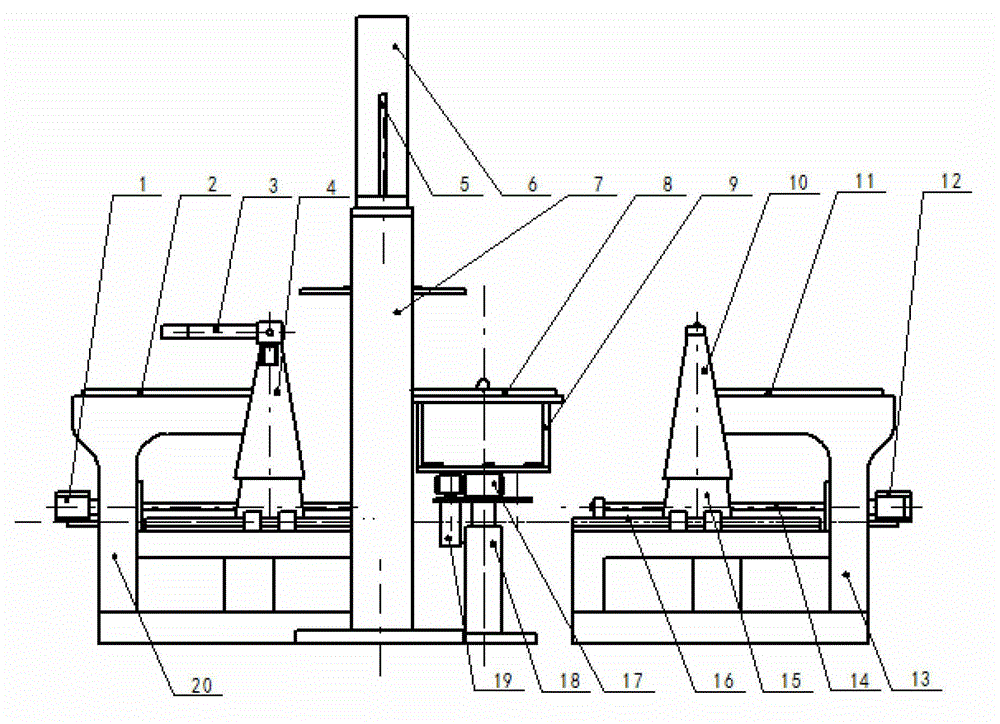

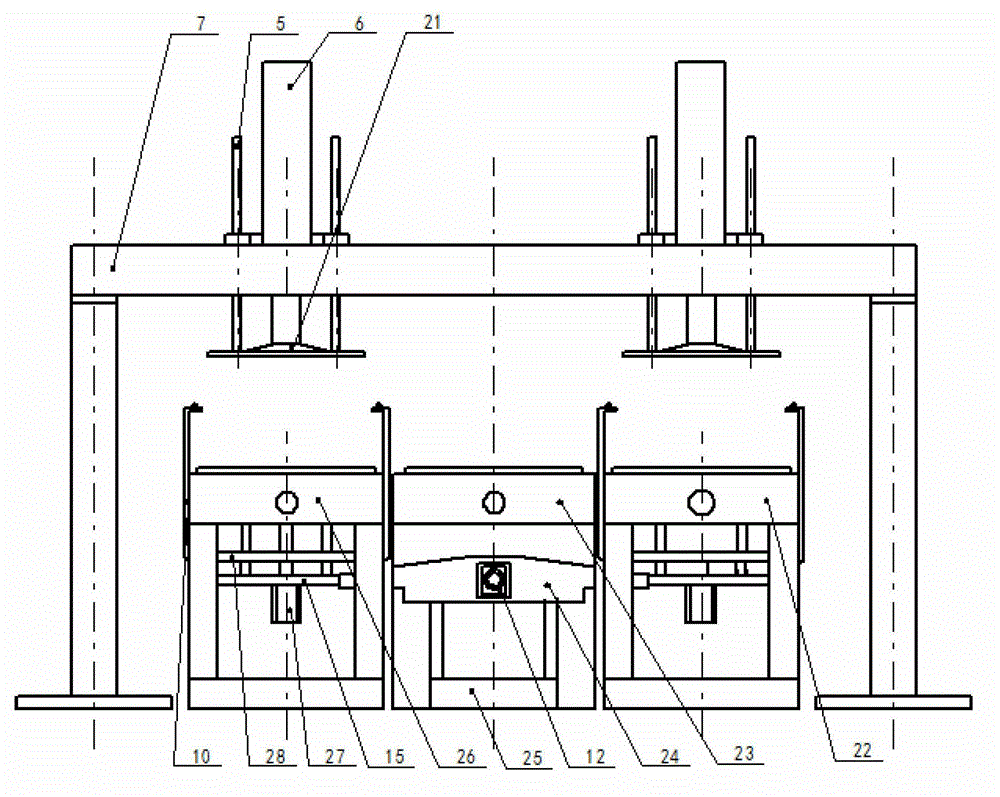

[0041]A continuous casting production line for rotary castings, which consists of two major parts: an intelligent control system and a mechanical system. Mold ejection system D and pouring system E. The molding system is installed at both ends of the conveyor belt. The transmission system is in the form of a rotary, and the conveyor belt is driven by a sprocket drive shaft; a sand feeding system is installed on one side of the molding system, and the other side The core placement machine is installed on the side, the pouring system is installed on the side of the conveyor belt on the side of the core placement machine, and the mold ejection system is installed on the side of the conveyor belt on the side of the sand loading system. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com