Production method of corrosion resistant alloy plates and split type pouring die used by same

A corrosion-resistant alloy and split-type technology, which is applied in the field of production methods and split-type casting molds, can solve the problems of high energy consumption and complicated processing procedures, simplify the process, reduce workload and intensity, and save processing hours Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The material of the plate produced is NiCu alloy, the length of the slab is 500mm, the width is 500mm, and the thickness is 200mm.

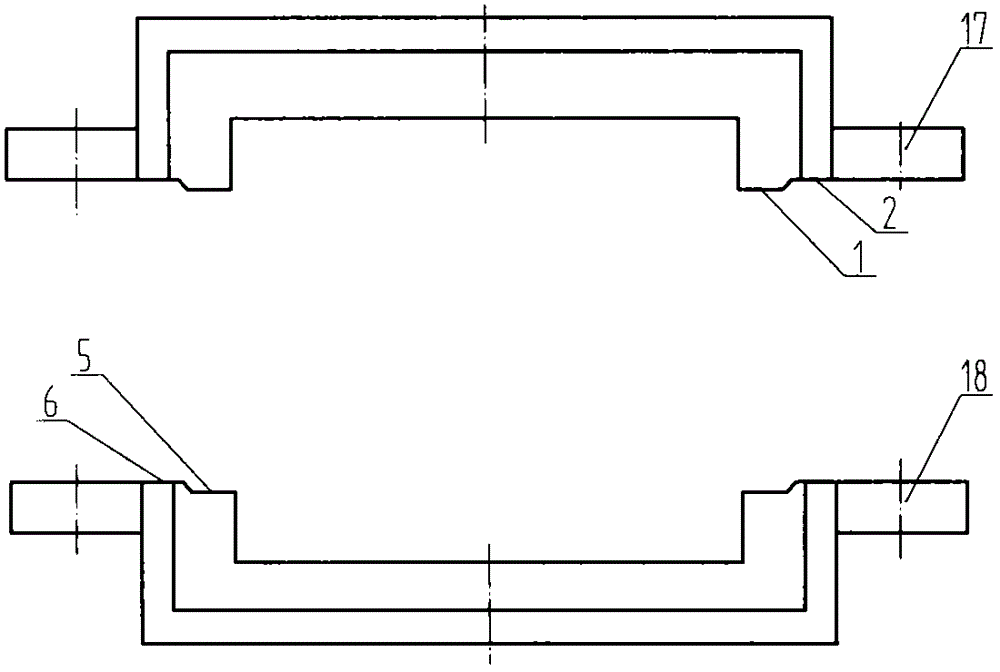

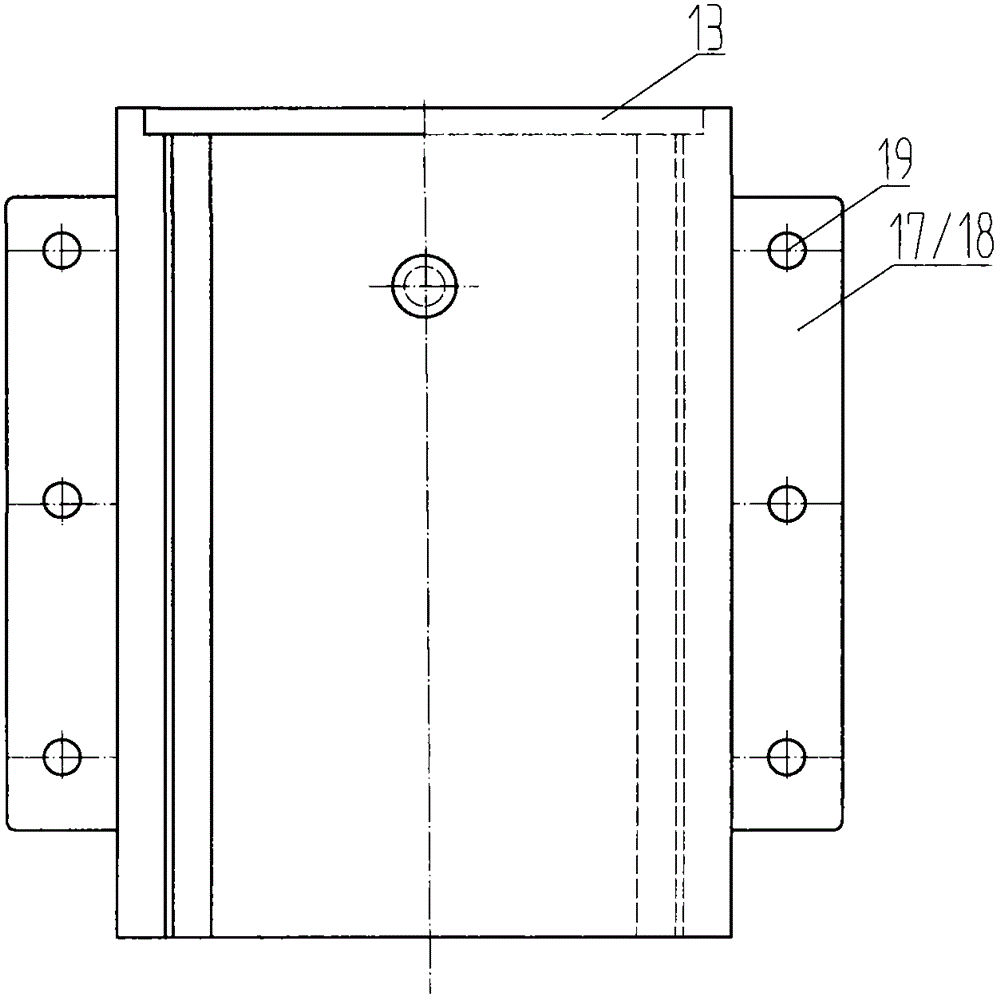

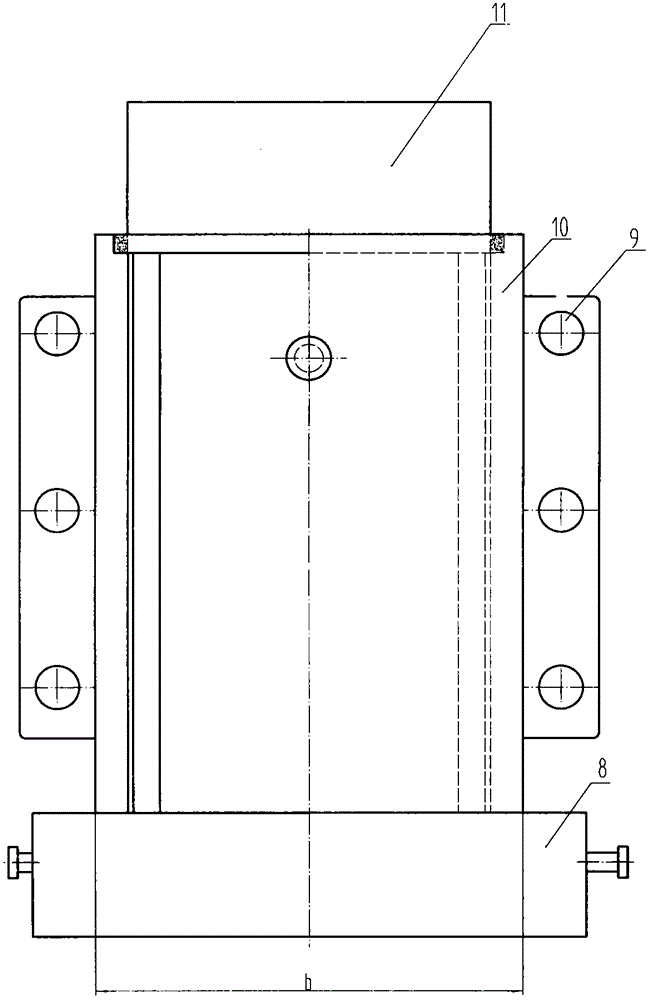

[0031] Using the split casting mold of the present invention, the cavity has no taper, the appearance is a square truss, the minimum thickness of the mold wall is 100mm, the maximum thickness is 175mm, and the taper is 15%. When pouring, the diameter of the gate is 13-15mm, The number of pouring holes is two, evenly distributed, for vacuum casting, and the vacuum degree is less than 10Pa.

[0032] The comparative example of embodiment 1

[0033] The material and specification of the plate produced are the same as in Example 1;

[0034] The ingot is poured with a taper integral casting mold of the prior art to obtain an ingot with a body size of Φ400 / Φ300×810mm; the ingot is peeled off with a lathe, and the riser is sawed with a sawing machine, and then the ingot is cast Carry out forging to remove the taper of the ingot itself to form a ro...

Embodiment 2

[0036] The specifications of the slab are: length 600mm, width 400mm, thickness 150mm;

[0037] The minimum thickness of the mold wall is 100mm, the maximum thickness is 150mm, and the taper is 8%, and the rest are the same as in embodiment 1.

[0038] The comparative example of embodiment 2

[0039] The material and specification of the plate produced are the same as in Example 2.

[0040] The size of the ingot body part is Φ340 / Φ340×830mm, and the rest are the same as the comparative example of embodiment 1.

Embodiment 3

[0042] The specifications of the slab: the length is 870mm, the width is 600mm, and the thickness is 300mm. The minimum wall thickness of the mold wall is 100, the thickest part is 200, the taper is 11.5%, and the rest are the same as in embodiment 1.

[0043] The comparative example of embodiment 3

[0044] The material and specification of the plate produced are the same as in Example 3.

[0045] The size of the ingot body part is Φ600 / Φ530×815mm, and the rest are the same as the comparative example of embodiment 1.

[0046] The corrosion-resistant alloy plate produced by the method of the present invention and the mechanical performance contrast of the corrosion-resistant alloy plate produced by the prior art in table 1

[0047]

[0048] In this table, the width of the sheet corresponds to the length of the slab in the corresponding examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com