Method for producing low chlorine high purity magnesia by soda ash method

A magnesium oxide, high-purity technology, applied in magnesium oxide and other directions, can solve the problems of high energy consumption, small particles, difficult washing and dehydration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

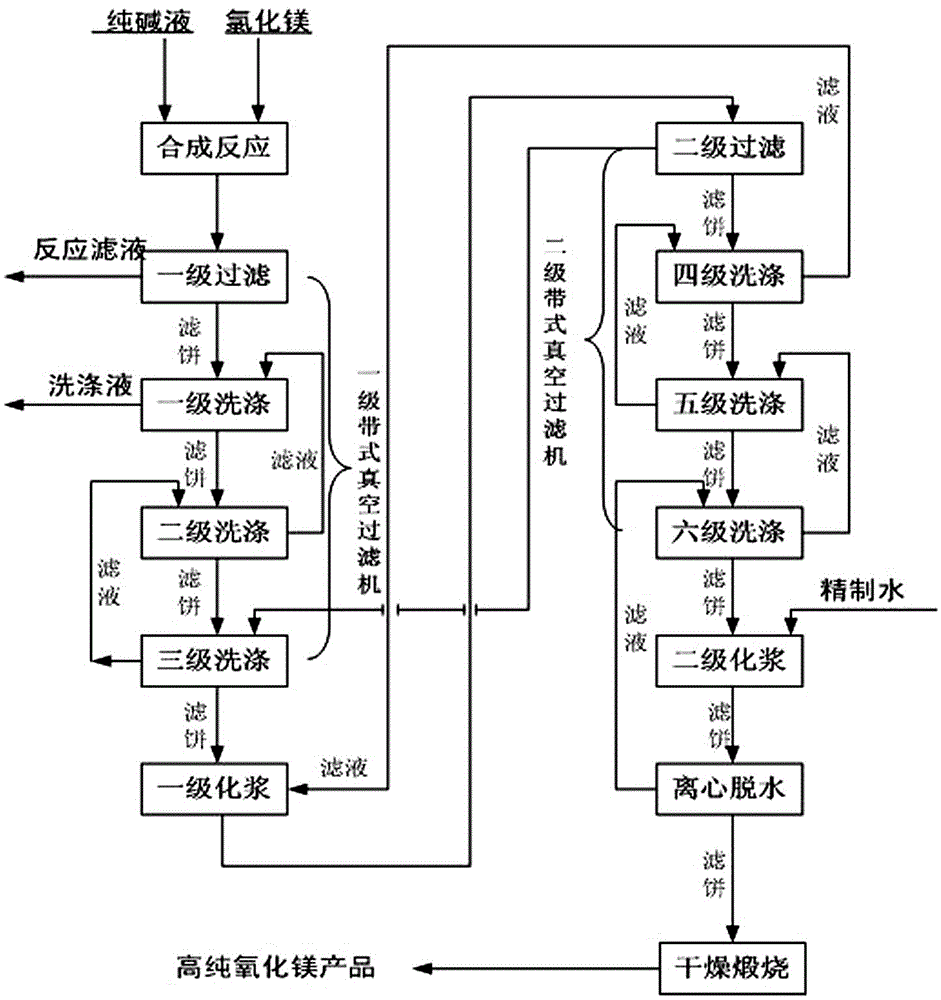

[0012] A method for producing low-chlorine high-purity magnesium oxide by a soda ash method is characterized in that it comprises the following steps:

[0013] Weigh 2000kgMgCl 2 .6H 2 O is added to the stirring tank, put into 4000 L, 60 ℃ hot water, and fully stirred, then the magnesium chloride solution is added to the sand filter, the solid particles in it are filtered, added to the enamel reaction kettle, and heated to 80°C. The soda ash solution of total alkali at 180 g / L enters the metering tank, wherein the volume is 5000 L, and is added to the reaction kettle for reaction. The total volume of the filtrate after the reaction is 9 m 3 , and then enter the first-stage belt filter, pass through the first-stage filtration section, the first-stage washing section, the second-stage washing section, and the third-stage washing section, and then wash in the first-stage pulp tank, and then enter the second-stage belt filter The secondary filtration section, the fourth-stage w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com