Purification method for electronic grade isopropanol recovered liquid

The technology of an electronic grade isopropyl alcohol and a refining method is applied in the refining field of the electronic grade isopropyl alcohol recovered liquid, which can solve problems such as defects in the manufacturing process, and achieve the effects of saving energy and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

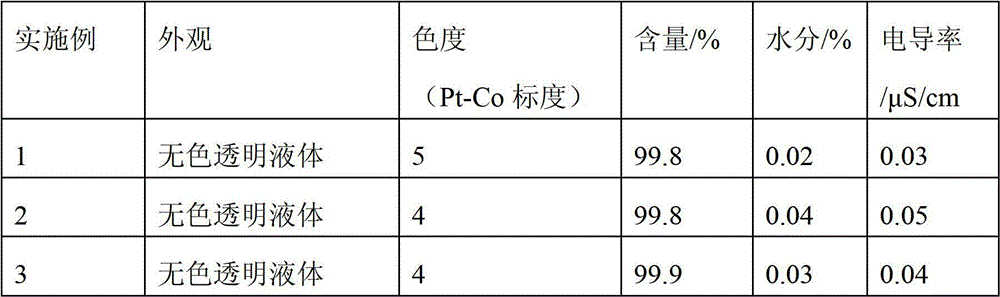

Embodiment 1

[0019] A method for refining electronic grade isopropanol recovery liquid, comprising the following steps,

[0020] (1) Add 100kg of activated carbon and 2 tons of anhydrous calcium chloride to 10 tons of isopropanol recovery solution containing 25% water, decolorize and remove water from the isopropanol recovery solution, and then filter to remove activated carbon, calcium chloride, and isopropanol Some solid impurities in the propanol recovery liquid, thereby obtain 8.5 tons of isopropanols of content 88%.

[0021] (2) Add 8.5 tons of isopropanol obtained in step (1) to 100 kg of dehydrating agent calcium oxide, and after reflux for 5 hours, remove the solid by filtration, and pass the isopropanol filtrate through an ion exchange resin column to remove metals in the isopropanol filtrate Impurities such as ions were removed to obtain 7.5 tons of purer isopropanol, and its conductance was 20 μS / cm.

[0022] (3) After rectifying 7.5 tons of isopropanol obtained in step (2), th...

Embodiment 2

[0024] A method for refining electronic grade isopropanol recovery liquid, comprising the following steps,

[0025] (1) Add 120kg of activated carbon and 2.1 tons of anhydrous calcium chloride to 10 tons of isopropanol recovery solution containing 20% water, decolorize and remove water from the isopropanol recovery solution, and then filter to remove activated carbon, calcium chloride, and isopropanol Some solid impurities in the propanol recovery liquid, thereby obtain 9 tons of isopropanols of content 88%.

[0026] (2) Add 9 tons of isopropanol obtained in step (1) to 120 kg of dehydrating agent calcium oxide, and after reflux for 4 hours, remove the solid by filtration, and pass the isopropanol filtrate through an ion exchange resin column to remove the metal in the isopropanol filtrate Impurities such as ions were removed to obtain 7.8 tons of purer isopropanol, and its conductance was 25 μS / cm.

[0027] (3) After rectifying 7.8 tons of isopropanol obtained in step (2),...

Embodiment 3

[0029] A method for refining electronic grade isopropanol recovery liquid, comprising the following steps,

[0030] (1) Add 320kg of activated carbon and 2.5 tons of anhydrous calcium chloride to 10 tons of isopropanol recovery liquid containing 27% water, decolorize and remove water from the isopropanol recovery liquid, and then filter to remove activated carbon, calcium chloride, and isopropanol Some solid impurities in the propanol recovery liquid, thereby obtain 8.3 tons of isopropanols of content 87%.

[0031] (2) Add 8.3 tons of isopropanol obtained in step (1) to 150 kg of dehydrating agent calcium oxide, and after refluxing for 3 hours, remove the solid by filtration, and pass the isopropanol filtrate through an ion exchange resin column to remove metals in the isopropanol filtrate Impurities such as ions were removed to obtain 7.4 tons of purer isopropanol, and its conductance was 30 μS / cm.

[0032] (3) After rectifying 7.4 tons of isopropanol obtained in step (2), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com