Biomass pyrolysis combustion furnace

A biomass pyrolysis and combustion furnace technology, which is applied in the field of biomass pyrolysis and combustion, biomass pyrolysis combustion furnace, can solve the problem of unfavorable recycling of waste and residue, insufficient combustion of materials, insufficient combustion or pyrolysis, etc. problem, to achieve the effect of complete pyrolysis, complete combustion and full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

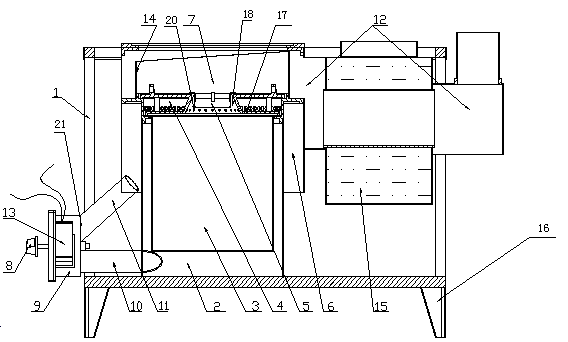

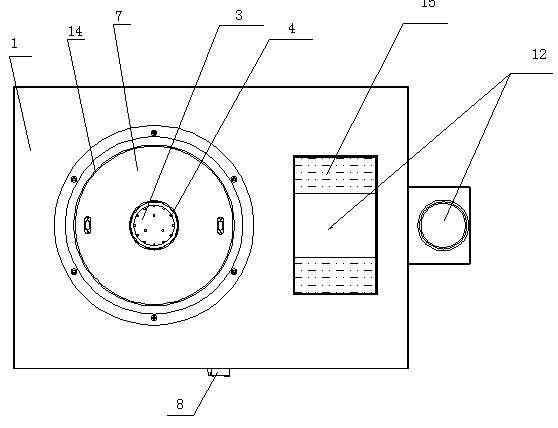

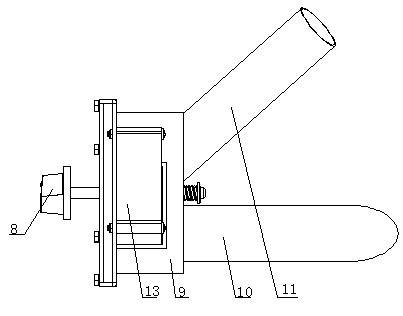

[0049] A biomass pyrolysis combustion furnace, comprising a bracket, a furnace shell, an air inlet and a wind cap arranged on the furnace shell, the furnace shell is arranged on the support, the furnace shell is located in the furnace shell, and the air inlet is arranged on the furnace shell, It is characterized in that: the air cap has an upper and lower structure and forms a secondary air supply chamber, and a truncated conical ignition cavity is arranged axially in the middle, the bottom of the furnace has holes, and a gap is arranged between the bottom of the furnace and the furnace shell. The primary air supply chamber and the air inlet are respectively connected to the primary air supply chamber and the secondary air supply chamber, and a combustion chamber is formed between the wind cap and the upper inner wall of the furnace shell.

[0050] In the above embodiment, the materials in the furnace are ignited first, and then the hood is covered, so that the materials in the...

Embodiment 2

[0052]A biomass pyrolysis combustion furnace, comprising a bracket, a furnace shell, an air inlet and a wind cap arranged on the furnace shell, the furnace shell is arranged on the support, the furnace shell is located in the furnace shell, and the air inlet is arranged on the furnace shell, It is characterized in that: the air cap has an upper and lower structure and forms a secondary air supply chamber, and a truncated conical ignition cavity is arranged axially in the middle, the bottom of the furnace has holes, and a gap is arranged between the bottom of the furnace and the furnace shell. The primary air supply chamber and the air inlet are respectively connected to the primary air supply chamber and the secondary air supply chamber, and a combustion chamber is formed between the wind cap and the upper inner wall of the furnace shell. A layer of the wind cap close to the furnace is provided with pre-combustion air supply holes.

Embodiment 3

[0054] A biomass pyrolysis combustion furnace, comprising a bracket, a furnace shell, an air inlet and a wind cap arranged on the furnace shell, the furnace shell is arranged on the support, the furnace shell is located in the furnace shell, and the air inlet is arranged on the furnace shell, It is characterized in that: the air cap has an upper and lower structure and forms a secondary air supply chamber, and a truncated conical ignition cavity is arranged axially in the middle, the bottom of the furnace has holes, and a gap is arranged between the bottom of the furnace and the furnace shell. The primary air supply chamber and the air inlet are respectively connected to the primary air supply chamber and the secondary air supply chamber, and a combustion chamber is formed between the wind cap and the upper inner wall of the furnace shell. The side wall of the ignition chamber is provided with a secondary air supply hole communicating with the secondary air supply chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com