Power supply assembly debugging device of photodetection equipment

A photoelectric detection and equipment technology, applied in the field of power supply component debugging devices, can solve the problems of testing equipment stability and load capacity detection and evaluation, inability to accurately detect voltage stability, voltage ripple magnitude and phase sequence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

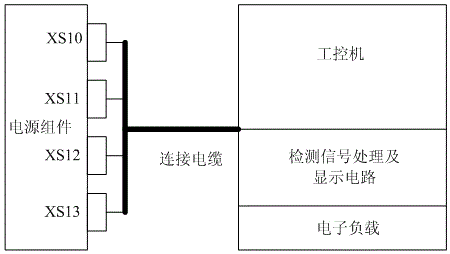

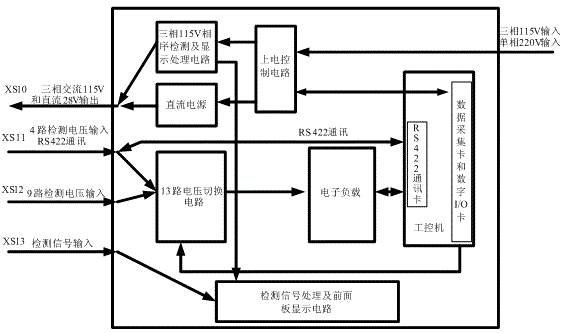

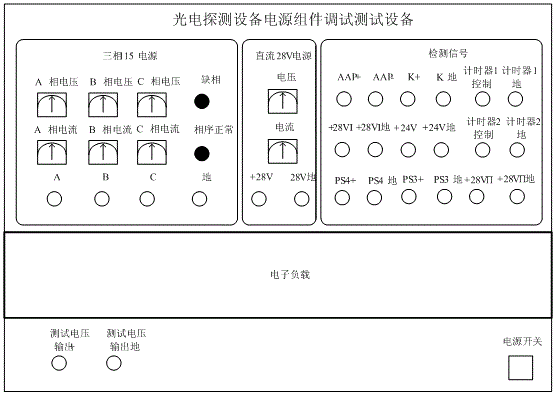

[0020] For the purpose of simple debugging and compact equipment, the composition block diagram of the power supply component debugging device of photoelectric detection equipment is as follows: figure 1 Shown: The chassis of the power supply component debugging device of photoelectric detection equipment adopts Rittal 12U standard chassis, and the industrial computer, detection signal processing, front panel display circuit and electronic load are arranged in sequence from top to bottom in the chassis. The industrial computer adopts 12.1"TFT LCD display, with LCD backlight and control switch on the front panel, equipped with 14-slot industrial backplane, stable performance and strong expandability. The lower part of the casing is equipped with a pull-out keyboard with a touch-sliding mouse board, and dual high-speed fans are built in the chassis for good heat dissipation , suitable for industrial site man-machine interface, process control and other occasions with large electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com