Multi-dimensional folded flexible solar battery pack and manufacturing method thereof

A technology of solar cells and manufacturing methods, applied in the field of solar photovoltaics, can solve the problems of short design life of metal wires, limited service life, broken metal wires, etc., to ensure service life and good electrical performance, increase service life, The effect of increasing the strength of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

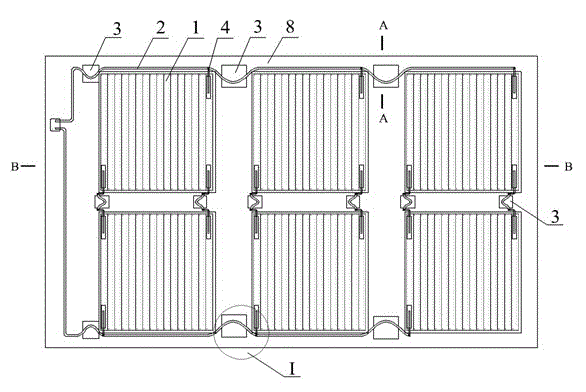

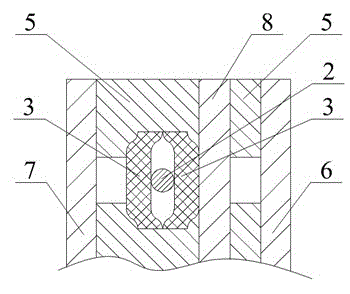

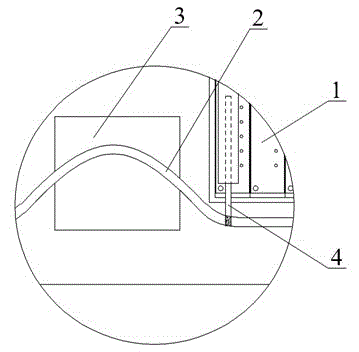

[0030] See figure 1 , the structure of the multi-dimensional foldable flexible solar cell module in this embodiment is sequentially laminated with a backsheet material 7, an adhesive film 5, a plurality of flexible solar cell chips 1 placed at intervals, a shielding material 8, an adhesive film 5, and a front sheet material 6 As a result, the flexible solar battery chips 1 are arranged in 3 rows and 2 rows, and there are gaps between adjacent battery chips to form the folding area of the battery module. The wires connected in series and parallel of the flexible solar cell chips 1 are welded on the electrode lead-out strips 4 of the battery chips, multiple flexible solar cell chips 1 are connected in series and parallel, and the adhesive film 5 where the wires are laid in the folded area is hollowed out to form a place for placing wires 2, and a braid 3 is placed above and below the hollowed out film. The size of the braid 3 is larger than the hollowed out size of the film. T...

Embodiment 2

[0038] The fabrication method of the multi-dimensionally folded flexible solar cell module is as follows:

[0039] First cut the front plate material 6, the back plate material 7, the adhesive film 5, the flexible solar cell chip 1 and the shielding material 8 according to the designed size, as well as the connecting wire 2 and the braid 3 with appropriate length specifications, in order from bottom to top Laminate the backsheet material 7 with the adhesive layer facing up, and laminate the adhesive film 5 on the adhesive layer. The adhesive film 5 should cover the entire backsheet material 7, and place the flexible solar cell chip 1 on the adhesive film 5 according to the designed size. When placing the battery chip, the distance of the folded part is reserved according to the design size, and the flexible solar battery chip 1 is positioned.

[0040] The flexible solar cell chips 1 are connected in series and parallel with each other with the wire 2, the wire 2 is welded on t...

Embodiment 3

[0051] In this embodiment, on the basis of embodiments 1 and 2, a protective layer of the flexible solar cell chip is added. The flexible solar cell core board is composed of multiple flexible solar cell chips connected in series and parallel. The folding area of the battery module is reserved between adjacent flexible solar cell chips, and the adhesive film where the wire is laid in the folding area is hollowed out to form an inner groove for placing the wire. . A protective layer is installed on the light-receiving surface and / or the backlight surface of each battery chip. The protective layer of the light-receiving surface of the flexible solar cell core board is a transparent polymer material, which is a material with high tensile strength, good light transmission, high temperature resistance, and ultraviolet resistance, such as polyethylene terephthalate (PET ), the adhesive film is made of photovoltaic adhesive film material, which can produce cross-linking at high te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com