Production method for freeze-dried lemon sustained-release tablet

A manufacturing method and technology of sustained-release tablets, which are applied in the field of manufacture of freeze-dried lemon sustained-release tablets, can solve the problems of poor taste and flavor, loss of nutritional components, short shelf life, etc., and achieve the effects of preventing loss, preventing oxidation, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

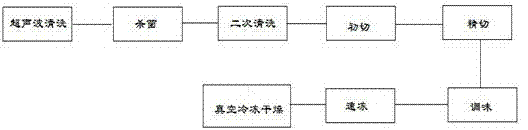

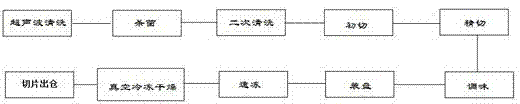

Image

Examples

Embodiment 1

[0035] A kind of manufacture method of freeze-dried lemon slow-release tablet, comprises the following steps:

[0036] Ultrasonic cleaning: first use ultrasonic cleaning to clean the dirt and impurities in the deep grooves and crevices of lemon fruit, and then use shower cleaning to clean the surface of the fruit after ultrasonic cleaning to remove the dirt attached to the surface.

[0037] Sterilization: use 100PPM chlorine dioxide solution to sterilize the fresh lemon fruit after the material selection step and the initial cleaning step, and the soaking time is 5 minutes;

[0038] Secondary cleaning: use sterile water to wash away the chlorine dioxide solution remaining in the sterilized fresh lemon fruit in a bubbling washing machine.

[0039] First cut: cut off the pedicles at both ends of the fresh lemon fruit after the second cleaning, the cut surfaces at both ends tend to be parallel, and the cut surface just meets the pulp;

[0040] Precise cutting: use a directional cu...

Embodiment 2

[0045] A kind of manufacture method of freeze-dried lemon slow-release tablet, comprises the following steps:

[0046] Ultrasonic cleaning: first use ultrasonic cleaning to clean the dirt and impurities in the deep grooves and crevices of lemon fruit, and then use shower cleaning to clean the surface of the fruit after ultrasonic cleaning to remove the dirt attached to the surface.

[0047] Sterilization: use 100PPM chlorine dioxide solution to sterilize the fresh lemon fruit after the material selection step and the initial cleaning step, and the soaking time is 7 minutes;

[0048] Secondary cleaning: use sterile water to wash away the chlorine dioxide solution remaining in the sterilized fresh lemon fruit in a bubbling washing machine.

[0049] First cut: cut off the pedicles at both ends of the fresh lemon fruit after the second cleaning, the cut surfaces at both ends tend to be parallel, and the cut surface just meets the pulp;

[0050] Precise cutting: use a directional ...

Embodiment 3

[0056] A kind of manufacture method of freeze-dried lemon slow-release tablet, comprises the following steps:

[0057] Ultrasonic cleaning: first use ultrasonic cleaning to clean the dirt and impurities in the deep grooves and crevices of the lemon fruit, and then use shower cleaning to clean the surface of the fruit after ultrasonic cleaning to remove the dirt attached to the surface;

[0058] Sterilization: use 100PPM chlorine dioxide solution to sterilize the fresh lemon fruit after the material selection step and the initial cleaning step, and the soaking time is 10 minutes;

[0059] Secondary cleaning: use sterile water to wash away the chlorine dioxide solution remaining in the sterilized fresh lemon fruit in a bubbling washing machine;

[0060] First cut: cut off the pedicles at both ends of the fresh lemon fruit after the second cleaning, the cut surfaces at both ends tend to be parallel, and the cut surface just meets the pulp;

[0061] Precise cutting: use a directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com