Bottom air inlet type cloth bag type dust collector

A bag dust collector and air-intake technology, which is applied to chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of high resistance of the dust collector and large footprint of the dust collector, and achieve improved dust collection and efficiency. High adsorption efficiency, increased cleaning effect, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the schematic diagrams.

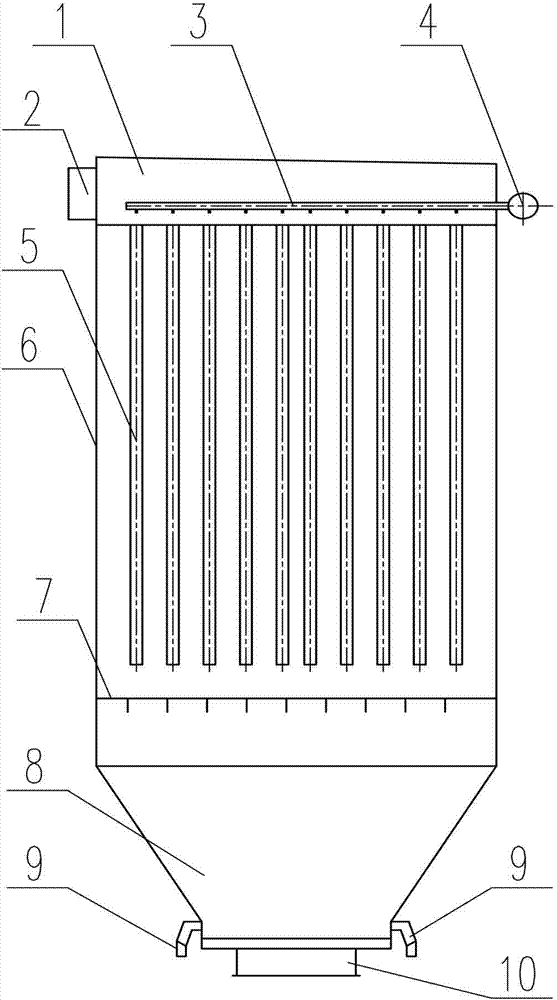

[0011] As shown in the figure, the bottom air intake type bag filter of the present invention includes a middle box 6, an upper box 1 is arranged above the middle box 6, a bag and a skeleton 5 are arranged in the middle box 6, and the middle box 6 The bottom of the ash hopper 8 is provided with an air inlet 10, the lower side wall of the ash hopper 8 is provided with a discharge port 9, and the number of discharge ports is 1 to 10; The lower part is provided with an air distribution plate 7, and the air distribution plate 7 is divided into 1-5 grade deflectors.

[0012] The function of the air distribution plate is to promote the uniform distribution of the air in the box.

[0013] The air outlet 2 is located on the side wall, top or edge of the upper box body 1 . In this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com