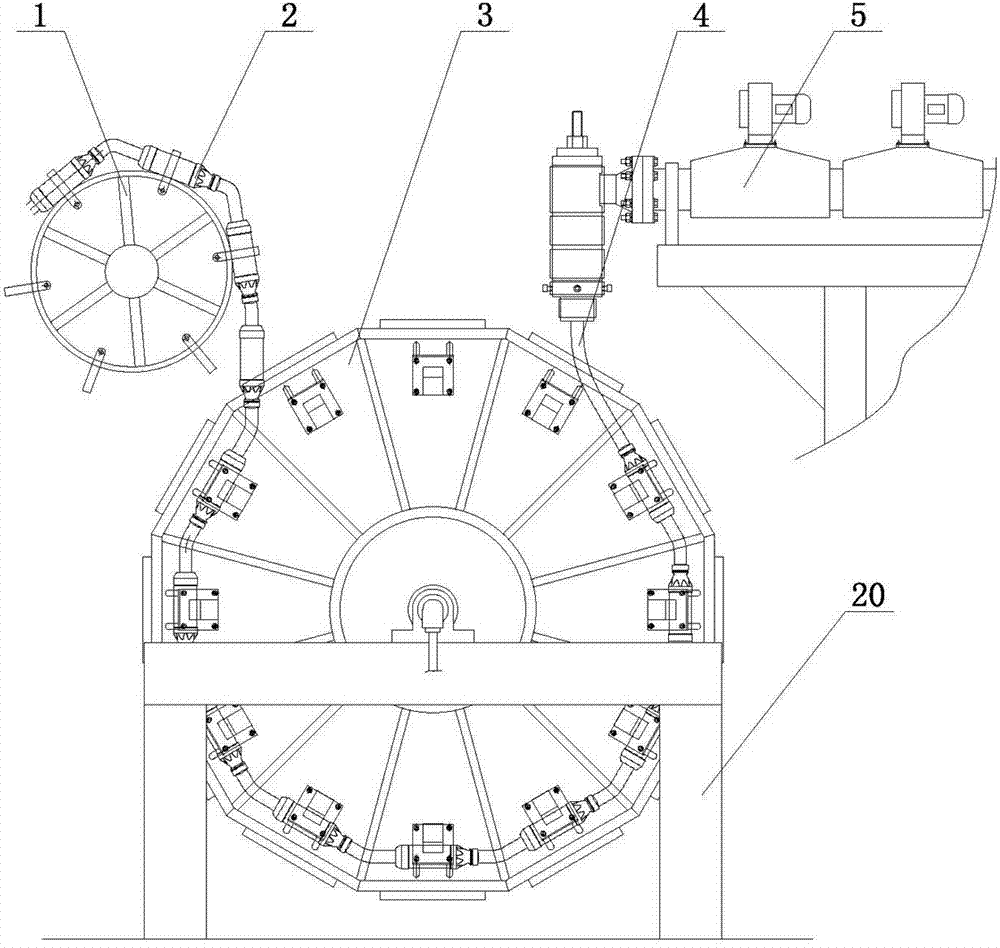

Double-row upright bottle blowing machine with turntable

A blow molding machine, vertical technology, applied in the field of double-row vertical turntable blow molding machines, can solve the problems of low efficiency, large floor space, large energy consumption, etc., to improve work efficiency, small floor space, and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

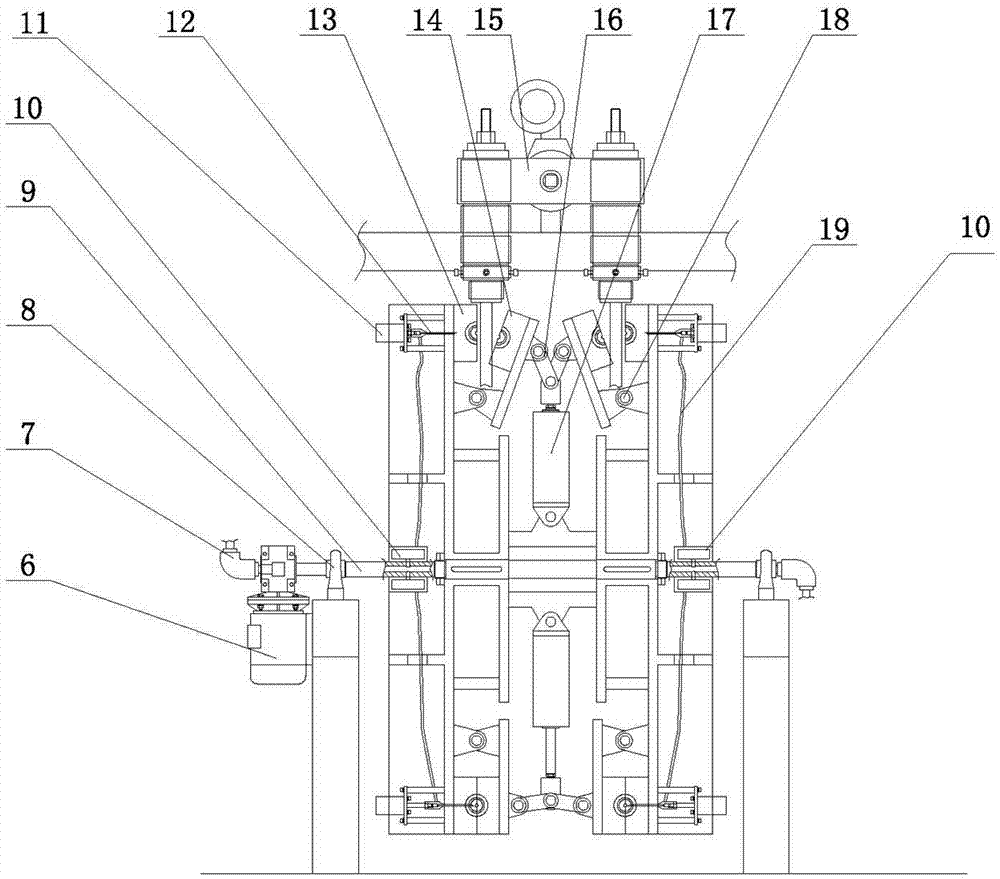

[0015] As shown in the figure, the double-row vertical turntable blow molding machine of the present invention includes a frame 20 provided with a rotating shaft 9, the frame 20 is provided with a bearing 8 with a seat, the rotating shaft 9 passes through the bearing 8 with a seat, and the rotating shaft 9 Run smoothly under the drive of geared motor 6. The rotating shaft 9 is connected to the fixed mold installation disk 3, and a mold is set on the fixed mold installation disk 3, and the fixed mold installation disk 3 is divided into two arrangements on the left and right, and several fixed molds 13 and The movable mold 14 and the fixed mold 13 are fixedly installed on the periphery of the fixed mold mounting plate 3, the blowing needle 12 faces the mold cavity, the movable mold 14 is actively connected to the fixed mold mounting plate 3 by the movable mold hinge 18, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com