Hybrid power system with dual clutch gearbox and control method

A technology of hybrid power system and double clutch, which is applied in hybrid vehicles, motor vehicles, transportation and packaging, etc., and can solve problems such as inability to control the transient response of the transmission system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

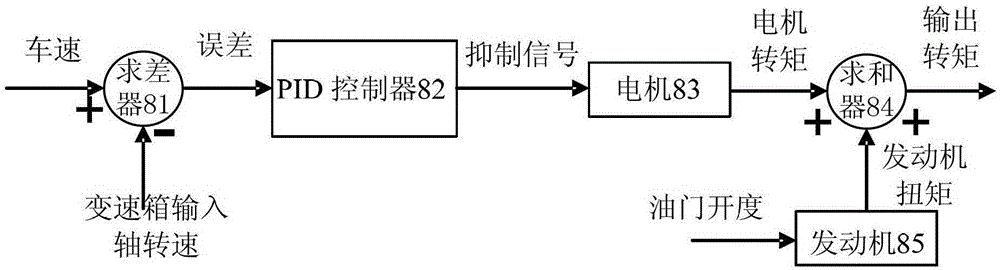

[0032] Such as figure 1 Shown, a hybrid system with a dual-clutch gearbox comprising:

[0033] The difference seeker 81 is used to obtain the difference between the vehicle speed and the rotational speed of the gearbox input shaft;

[0034] The PID proportional-integral-differential algorithm controller 82 uses the output of the difference seeker 81 as the input of the PID proportional-integral-differential algorithm controller 82, and obtains the motor torque correction suppression signal through the calculation of the PID proportional-integral-differential algorithm controller, and adjusts the motor 83 torque output;

[0035] The motor 83 adjusts the motor torque according to the inhibition signal;

[0036] Engine 85, adjust the engine 85 torque according to the throttle;

[0037] The summer 84 is used for adding the torque of the motor 83 and the torque of the engine 85 to obtain the output torque.

Embodiment 2

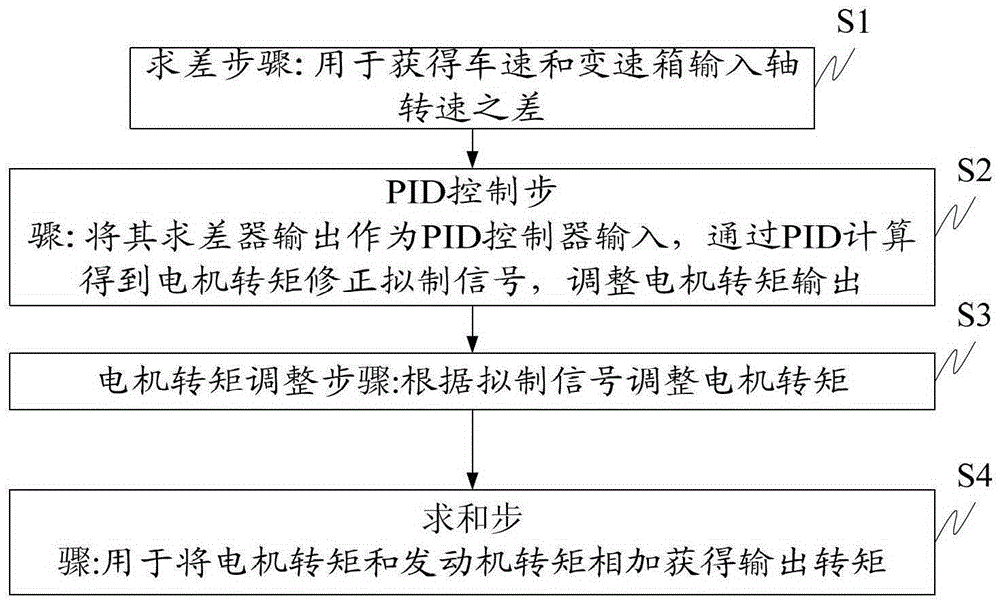

[0039] Such as figure 2 As shown, a hybrid control method with a dual-clutch gearbox includes the following steps:

[0040] S1. Step of seeking difference: used to obtain the difference between the vehicle speed and the rotational speed of the gearbox input shaft;

[0041] S2. PID proportional-integral-differential algorithm control step: use the output of the difference seeker as the input of the PID proportional-integral-differential algorithm controller, calculate the motor torque correction suppression signal through the PID proportional-integral-differential algorithm controller, and adjust the motor torque output;

[0042] S3. Motor torque adjustment step: adjust the motor torque according to the suppression signal;

[0043] S4. Summing step: for adding the motor torque and the engine torque to obtain the output torque.

[0044] Vehicle speed and gearbox input shaft rotational speed are control input signals, and their errors are input as PID proportional-integral-dif...

Embodiment 3

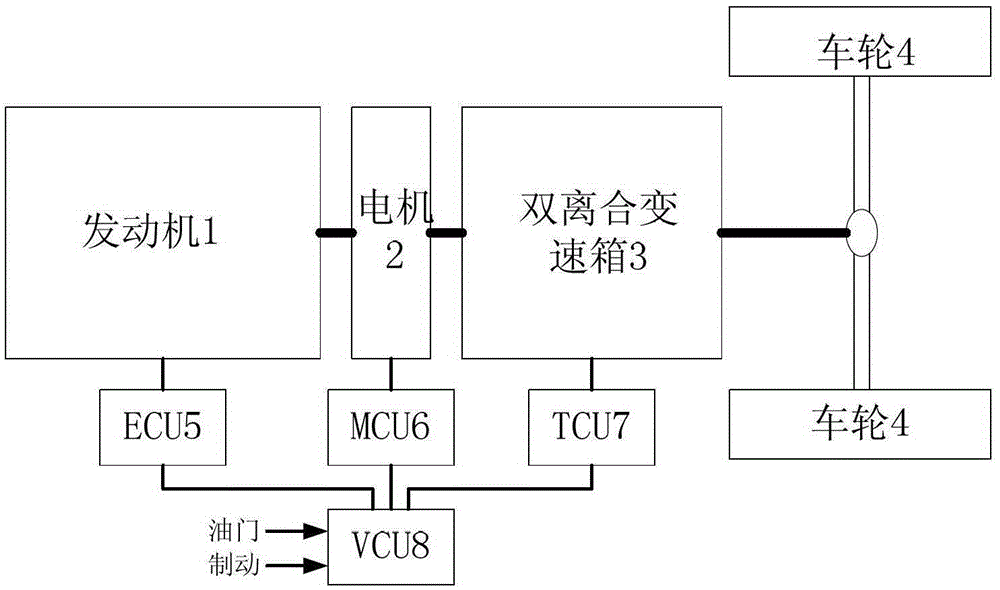

[0046] Such as image 3 As shown, a hybrid power system with dual-clutch gearbox includes: engine 1 and engine control unit ECU5, motor 2 and motor controller MCU6, dual-clutch gearbox 3 and dual-clutch gearbox controller TCU7, vehicle control The VCU8 is connected to the wheel 4, the dual clutch gearbox 3 is connected to the wheel 4, the engine 1 is connected to the engine control unit ECU5, the motor 2 is connected to the motor controller MCU6, the dual clutch gearbox 3 is connected to the dual clutch gearbox controller TCU7, and the engine control unit ECU5 The other end of the motor controller MCU6 and the dual-clutch gearbox controller TCU7 is connected to the vehicle controller VCU8, and a motor 2 is installed between the engine 1 and the dual-clutch gearbox 3 for hybrid drive, and the vehicle controller VCU8 receives the engine The information of control unit ECU5, motor controller MCU6, dual-clutch gearbox controller TCU7, as well as the signals of accelerator and brak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com