Fluidized bed boiler using combustion of coal gangues

A technology for fluidized bed boilers and coal gangue, which is applied in fluidized bed combustion equipment, burning fuel in a molten state, steam boilers, etc., can solve the problems of high ash content, low calorific value, low utilization rate of coal gangue, etc., and achieve thermal quality The effect of good exchange and full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

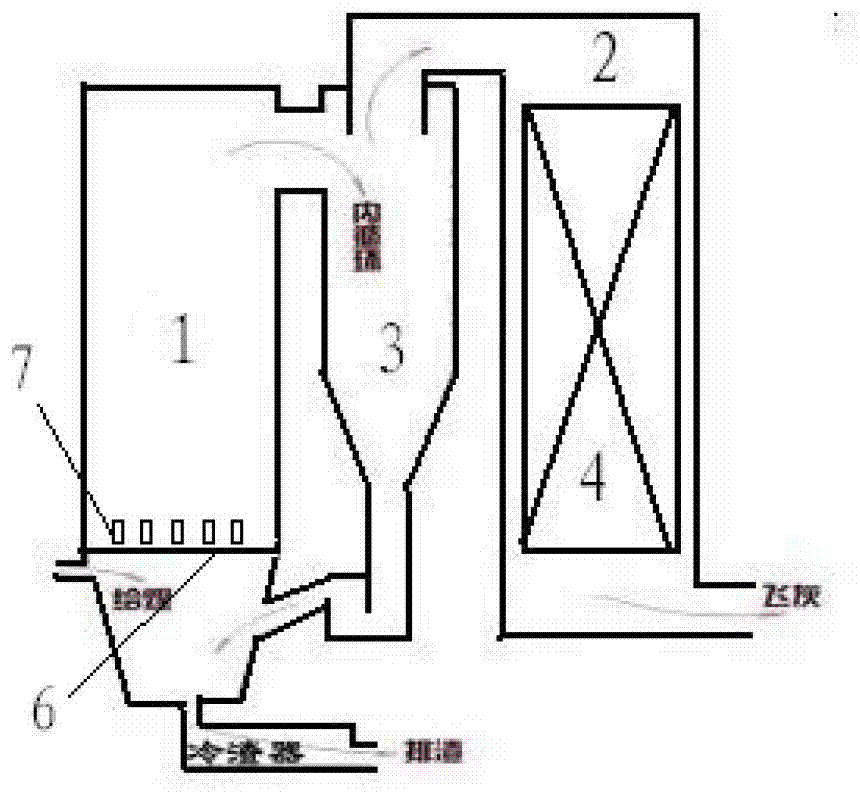

[0023] Example 1: An XF-SⅠ type circulating fluidized bed boiler for burning coal gangue

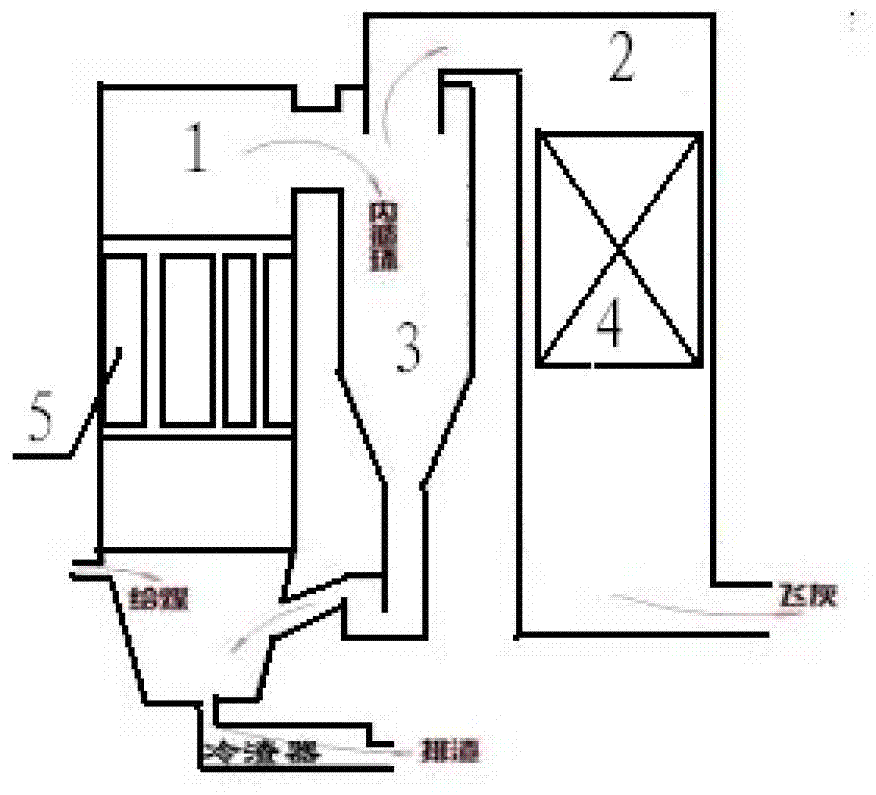

[0024] Circulating fluidized bed boiler for modification such as figure 2 As shown, it includes the furnace 1, the tail shaft 2, the circulation channel 3, the steaming heating surface 4, the water wall 5 and the air distribution plate.

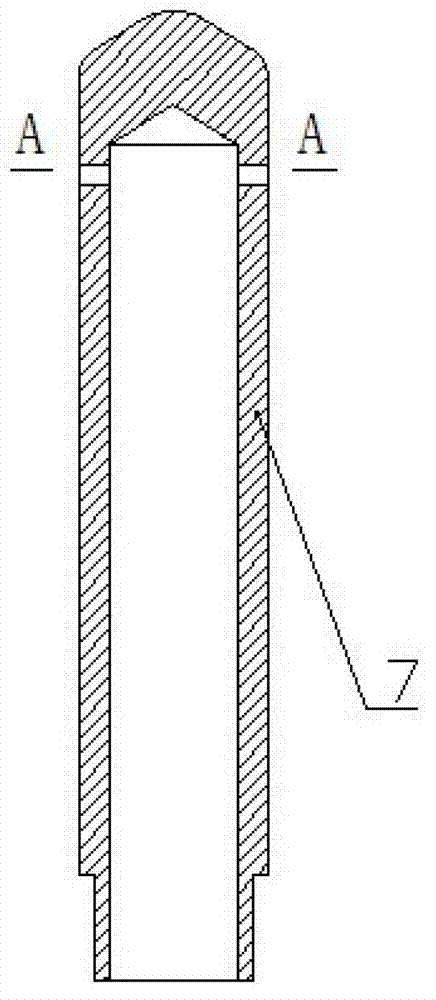

[0025] First install the cyclone hood 7 in the furnace 1, such as image 3 As shown, the cyclone hood 7 we use has holes on the side wall of the hood 7 to form an air flow channel, such as Figure 4 As shown, the orthographic projection of the airflow channel opening on the outer wall of the cyclone hood 7 does not coincide with the orthographic projection of the opening on the inner wall of the cyclone hood 7, and the deviation direction and angle are the same.

[0026] Secondly, remove the water wall in the furnace 1, such as figure 1 Shown.

[0027] After the coal gangue is fed into the furnace 1, it is ignited by charcoal, and a swirl flow is generated in ...

Embodiment 2

[0030] Using the circulating fluidized bed boiler in the above example 1, put in coal gangue with a calorific value of about 1000 kcal / kg, and retain part of the water wall in the furnace. The area of the water wall is 0.5 square meters per ton of steam. Increase the convection heat transfer surface, use wood to ignite it to burn, and measure the temperature of the furnace to be 900-950 degrees. If a saturation temperature of 194 degrees and 1.27 Mpa steam is required, 1 ton of coal gangue can produce 1,000 kilograms of qualified weight steam.

Embodiment 3

[0032] Using the circulating fluidized bed boiler in the above example 1, put coal gangue with a calorific value of about 900 kcal / kg, and retain part of the water wall in the furnace. The area of the water wall is 0.3 square meters per ton of steam. Increase the convective heat transfer surface, and use wood ignition to make it burn. The temperature of the furnace is measured to be 900-950 degrees. If a saturation temperature of 194 degrees and 1.27 MPa steam is required, 1 ton of coal gangue can produce 850 kg of qualified weight Steam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com