Slow wave structure of folding frame

A slow-wave structure, folding frame technology, applied in the direction of the circuit components of the transit time type electron tube, can solve the problems of limited application development, small coupling impedance of the traveling wave tube, etc., achieve high coupling impedance value, improve gain and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

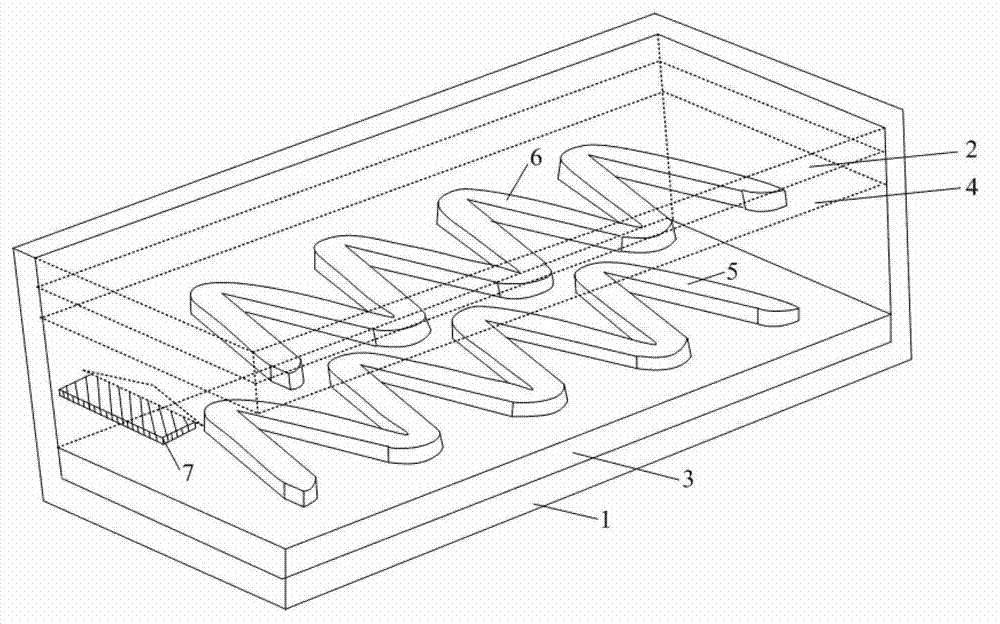

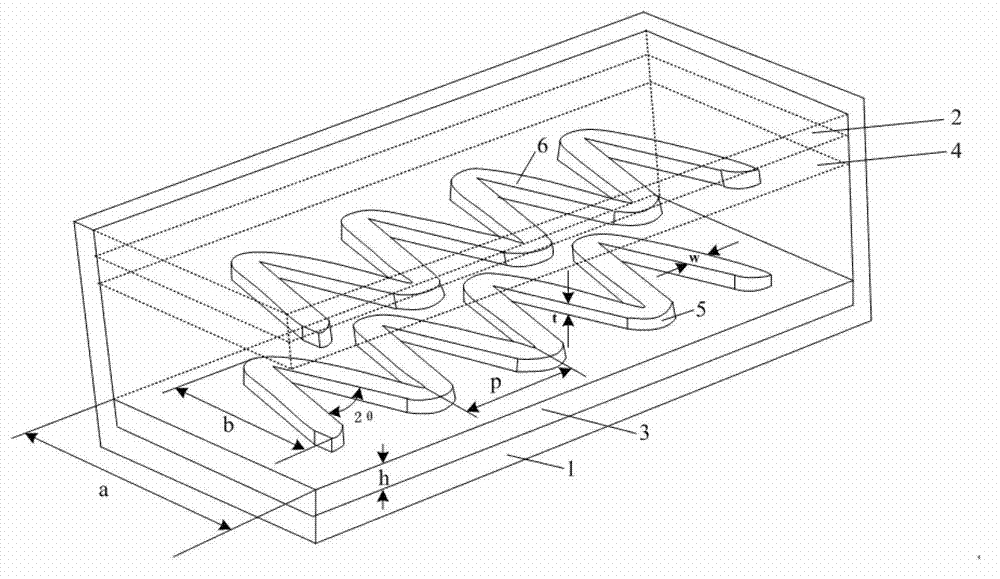

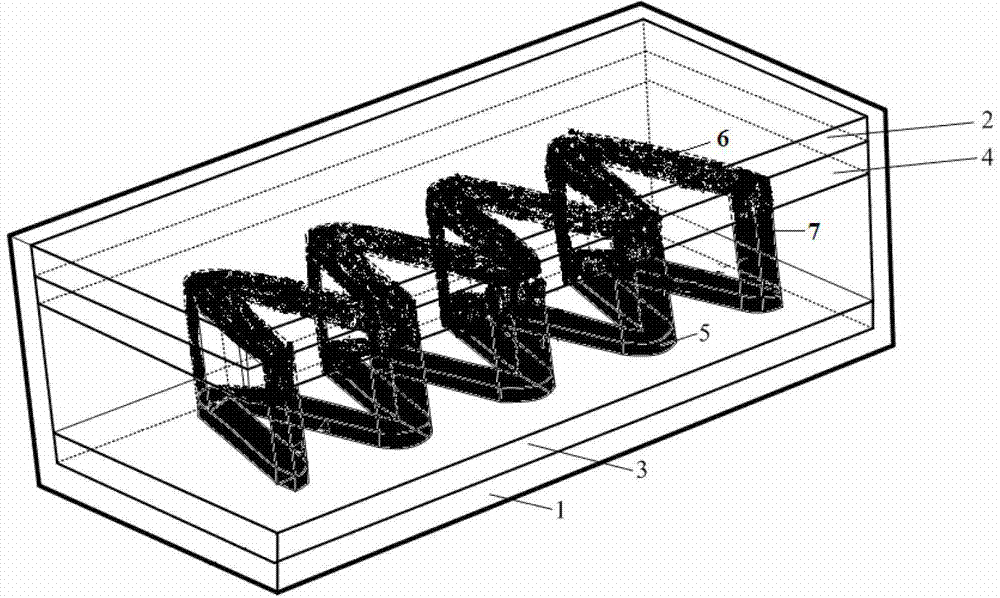

[0022] A folded-box slow-wave structure, such as image 3 As shown, it includes a lower metal base plate 1 and an upper metal base plate 2, the shape and size of the lower metal base plate 1 and the upper metal base plate 2 are the same and parallel to each other; the upper surface of the lower metal base plate 1 has a lower dielectric layer 3, and the upper metal base plate The lower surface of 2 has an upper dielectric layer 4, and the dielectric material and thickness of the lower dielectric layer 3 and the upper dielectric layer 4 are the same; the upper surface of the lower dielectric layer 3 has a lower metal microstrip line 5, and the lower surface of the upper dielectric layer 4 There is an upper metal microstrip line 6; the lower metal microstrip line 5 and the upper metal microstrip line 6 have the same line width, are periodically folded, and are mirror symmetrical to each other; each of the lower metal microstrip line 5 A fold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com