Nine-fruit primary pulp plant protein beverage and production method thereof

A plant protein beverage and production method technology, applied in the direction of milk substitutes, dairy products, applications, etc., can solve the problems of deterioration, particles that are not fine enough, and cannot be preserved, and achieve the effects of simple operation of the production process, maintaining stability, and extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Pecan 5kg; Badam 5kg; Pecan 5kg; Almond 5kg; Peanut 20kg; Macadamia nut 5kg; Soybean 10kg; Cashew nut 5kg; Hazelnut 5kg; White sugar 50kg; Honey 10kg Water 875kg

[0066] The production method of Benjiu fruit puree vegetable protein drink:

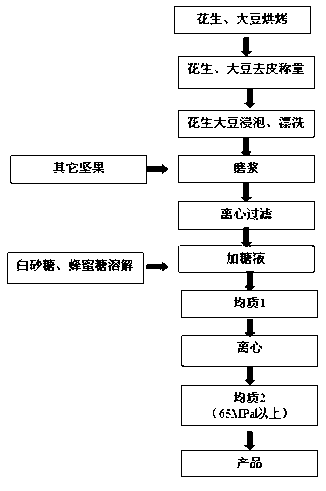

[0067] see figure 1 , comprising the steps of: (1) peeling the nuts; (2) soaking; (3) mixing and refining; (4) centrifuging; (5) adding white sugar and honey; (6) homogenizing; (7) centrifuging; (8) ) homogeneous.

[0068] Above-mentioned method comprises following specific processing steps:

[0069] 1) Peeling pecans, badam, almonds, soybeans and peanuts respectively;

[0070] 2) Soak peeled peanuts and soybeans for 1 hour;

[0071] 3) Mix hickory nuts, badam, pecans, almonds, peanuts, macadamia nuts, soybeans, cashew nuts, and hazelnuts, refine the pulp, filter with 200 mesh, and then put the filtered material liquid into the mixing tank;

[0072] 4) Centrifuge the filtered feed liquid in a centrifuge at a speed of 1400r / min,...

Embodiment 2

[0078] Pecan 10kg; Badam 10kg; Pecan 10kg; Almond 10kg; Peanut 20kg; Macadamia nut 10kg; Soybean 30kg; Cashew nut 5kg; Hazelnut 5kg; White sugar 55kg; Honey 5kg; Water 830kg

[0079] The production method of Benjiu fruit puree vegetable protein drink:

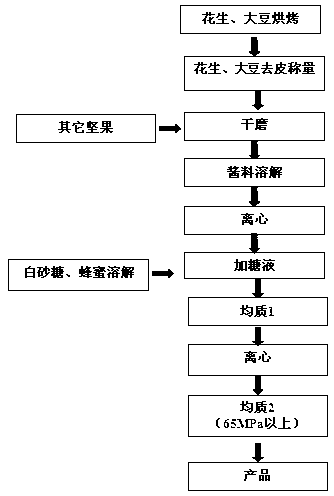

[0080] see figure 2 , including steps: (1) peeling nuts; (2) dry grinding; (3) dissolving; (4) centrifuging; (5) adding white sugar; (6) homogenizing; (7) centrifuging; (8) homogenizing .

[0081] Above-mentioned method comprises following specific processing steps:

[0082] 1) Peeling pecans, badam, almonds, soybeans and peanuts respectively;

[0083] 2) Peeled pecans, badam, pecans, almonds, peanuts, macadamia nuts, soybeans, cashews, hazelnuts and soybeans are dry ground;

[0084] 3) Heat the sauce obtained in step 2) to dissolve it in water, and pour the liquid into the mixing tank;

[0085] 4) Centrifuge the feed liquid in step 3) in a centrifuge at a speed of 2500r / min, and then pour it into a mixing tank;

[0086]...

Embodiment 3

[0091] Pecan 8kg; Badam 8kg; Pecan 8kg; Almond 8kg; Peanut 40kg; Macadamia 5kg; Soybean 20kg; Cashew 5kg; Hazelnut 5kg; White sugar 30kg; Water 863kg

[0092] The production method of Benjiu fruit puree vegetable protein drink:

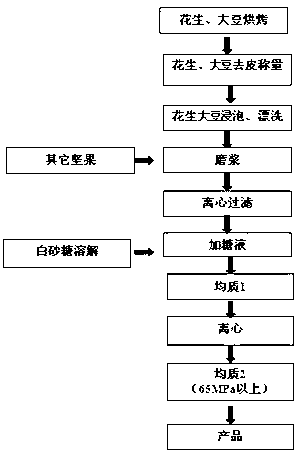

[0093] see image 3 , comprising the steps of: (1) peeling the nuts; (2) soaking; (3) mixing and refining; (4) centrifuging; (5) adding white sugar and honey; (6) homogenizing; (7) centrifuging; (8) ) homogeneous.

[0094] Above-mentioned method comprises following specific processing steps:

[0095] 1) Peeling pecans, badam, almonds, soybeans and peanuts respectively;

[0096] 2) Soak peeled peanuts and soybeans for 1 hour;

[0097] 3) Mix hickory nuts, badam, pecans, almonds, peanuts, macadamia nuts, soybeans, cashew nuts, and hazelnuts, refine the pulp, filter with 200 mesh, and then put the filtered material liquid into the mixing tank;

[0098] 4) Centrifuge the filtered feed liquid in a centrifuge at a speed of 2000r / min, and then pour it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com