Preparation method of powdered oil feed with whey powder

A technology of powdered oil and whey powder, which is applied in the field of preparation of powdered oil feed, can solve the problems of easy carrying of bacteria and viruses, low digestion and utilization rate, short storage time, etc., and achieve the effect of improving fluency, comprehensive absorption, and less hidden troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

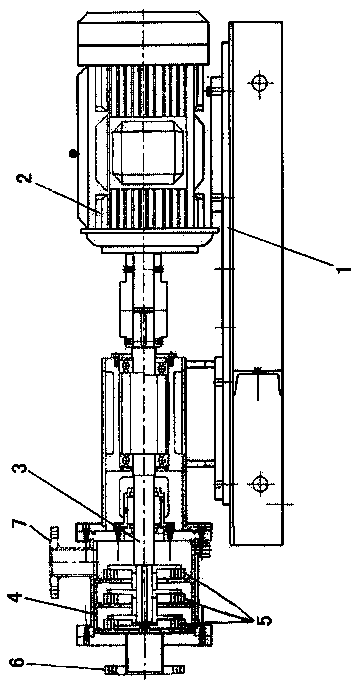

[0031] Embodiment 1: a kind of preparation method of the powdered oil feed with whey powder of this example, it puts 100kg whey powder, 200kg coconut oil, 200kg palm oil, 495kg soybean protein concentrate into 2000kg water, and temperature is controlled at 50- Between 100°C, add 5 kg of emulsifier, stir for 5 minutes, and then enter the emulsifier for processing. like figure 1 , the emulsification machine includes an emulsification machine frame 1, a motor 2 is arranged on the emulsification machine frame, the motor is connected to a rotating shaft 3, the rotating shaft is passed into the housing 4 and is connected to three sets of stators 5, and the outer end of the housing is provided with an emulsifying machine. Machine material inlet 6, the upper part of the shell is provided with emulsifying machine material outlet 7. The pressure at the inlet is 0.2MPa, and the pressure at the outlet is 0.2MPa. Through three sets of high-speed rotating stators (2900 rpm), the particle s...

Embodiment 2

[0032] Embodiment 2: a kind of preparation method of the powdered oil feed with whey powder of this example, 150kg whey powder, 150kg coconut oil, 200kg soybean oil, 125kg palm oil, 140kg soybean tissue protein, 100kg soybean meal and 125kg barley protein Put it into 2000kg of water, control the temperature between 50-100°C, add 10kg of emulsifier, stir for 5 minutes, and then enter the emulsifier for processing, such as figure 1 , the emulsification machine includes an emulsification machine frame 1, a motor 2 is arranged on the emulsification machine frame, the motor is connected to a rotating shaft 3, the rotating shaft is passed into the housing 4 and is connected to three sets of stators 5, and the outer end of the housing is provided with an emulsifying machine. Machine material inlet 6, the upper part of the shell is provided with emulsifying machine material outlet 7. The pressure at the feed inlet is 0.2MPa, and the pressure at the outlet is 0.2MPa. Through three sets...

Embodiment 3

[0033] Embodiment 3: a kind of preparation method of the powdered fat feed with whey powder of this example, 250kg whey powder, 195kg lard, 200kg palm oil, 140kg peanut protein and 200kg pea protein are put into 2000kg water, temperature is controlled at Between 50-100°C, add 15 kg of emulsifier, stir for 5 minutes, and then enter the emulsifier for processing, such as figure 1 , the emulsification machine includes an emulsification machine frame 1, a motor 2 is arranged on the emulsification machine frame, the motor is connected to a rotating shaft 3, the rotating shaft is passed into the housing 4 and is connected to three sets of stators 5, and the outer end of the housing is provided with an emulsifying machine. Machine material inlet 6, the upper part of the shell is provided with emulsifying machine material outlet 7. The pressure at the feed inlet is 0.2MPa, and the pressure at the outlet is 0.2MPa. Through three sets of high-speed rotating stators (2900 rpm), the parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com