Method for specific continuous separation of micro-scale particles

A separation method and specific technology, applied in the field of chemistry, can solve the problem of insignificant molecular thermal movement, achieve high-throughput continuous adjustable multi-channel particle separation, overcome pipeline blockage, and achieve the best separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

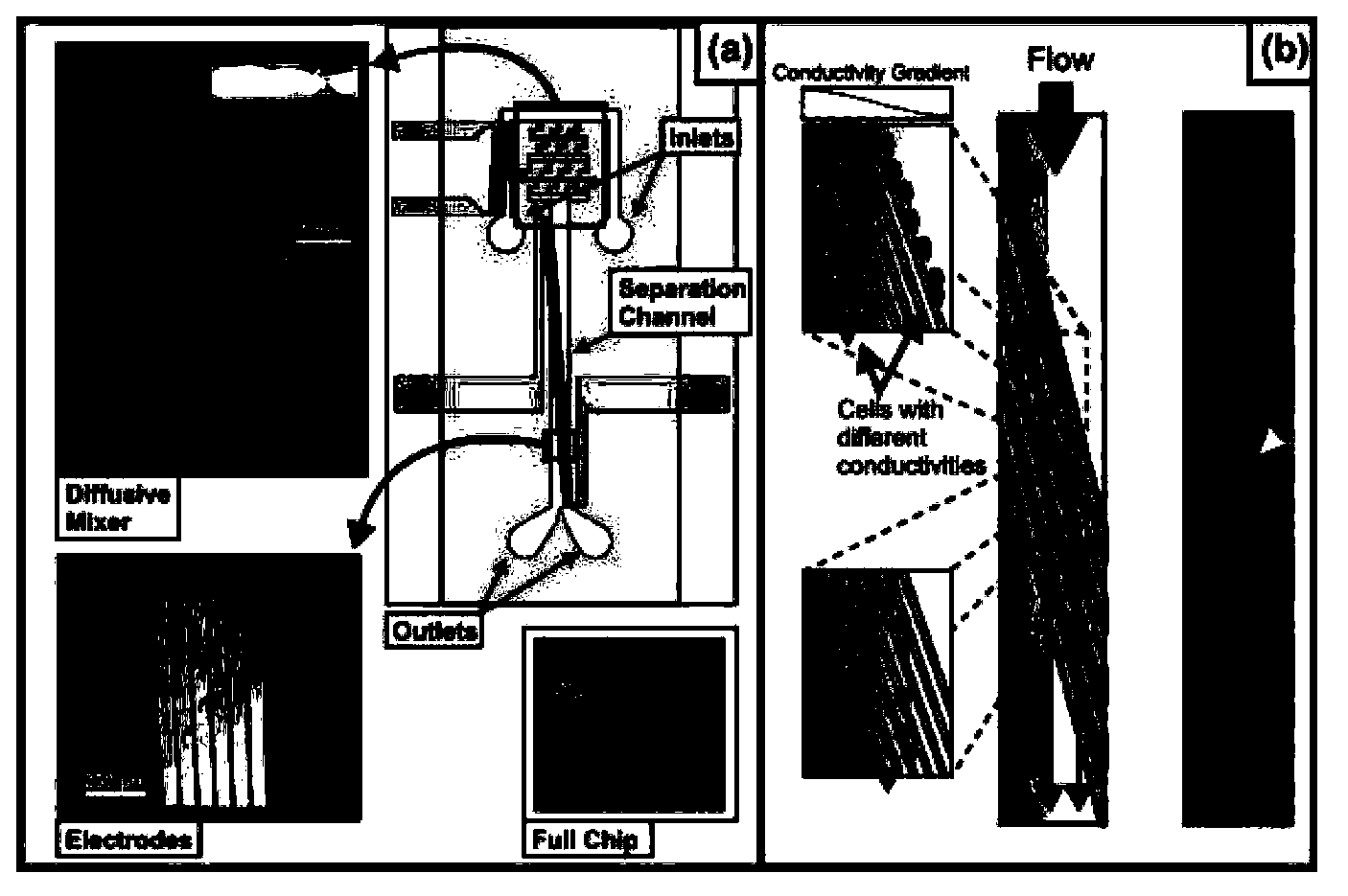

[0086] according to Figure 10 Finally, the ITO electrode is bonded to the silicon wafer (channel), and the structure of the dielectrophoretic microfluidic chip with specific and continuous separation of micro-scale particles is obtained. Figure 11 shown in Figure 11 , the leads are connected to the ITO electrodes through conductive tape.

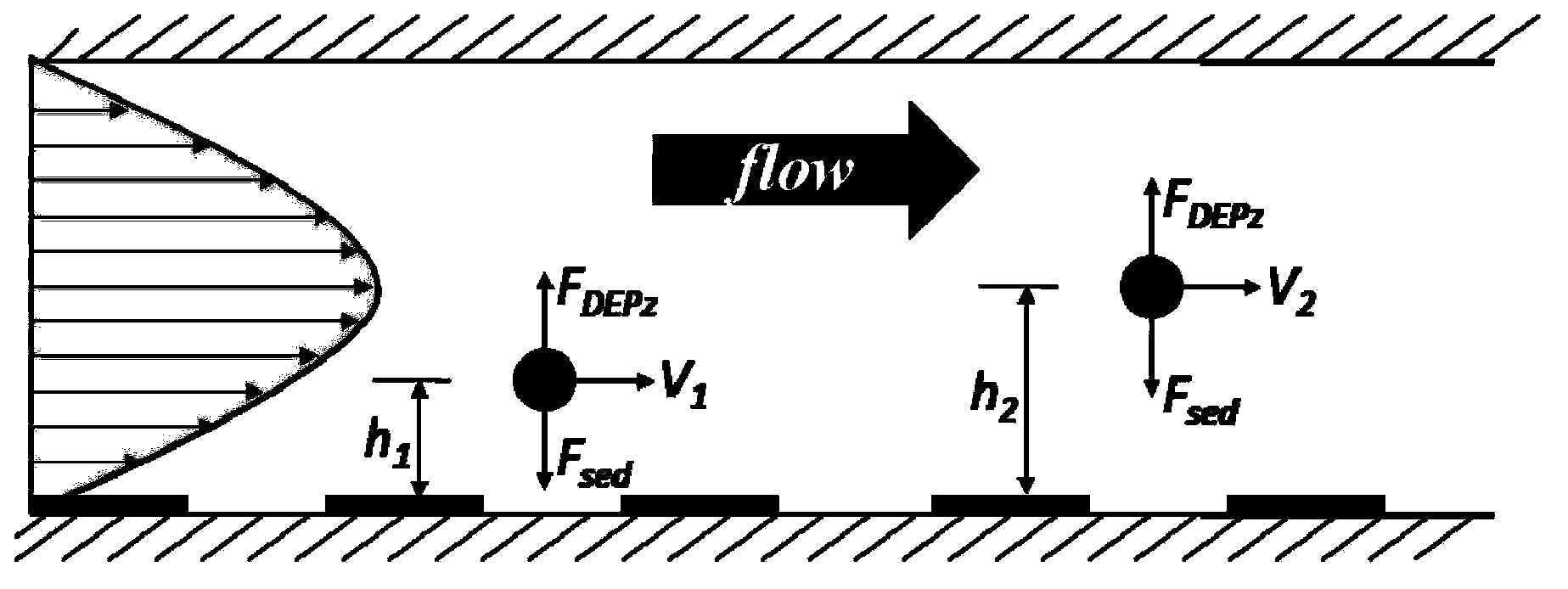

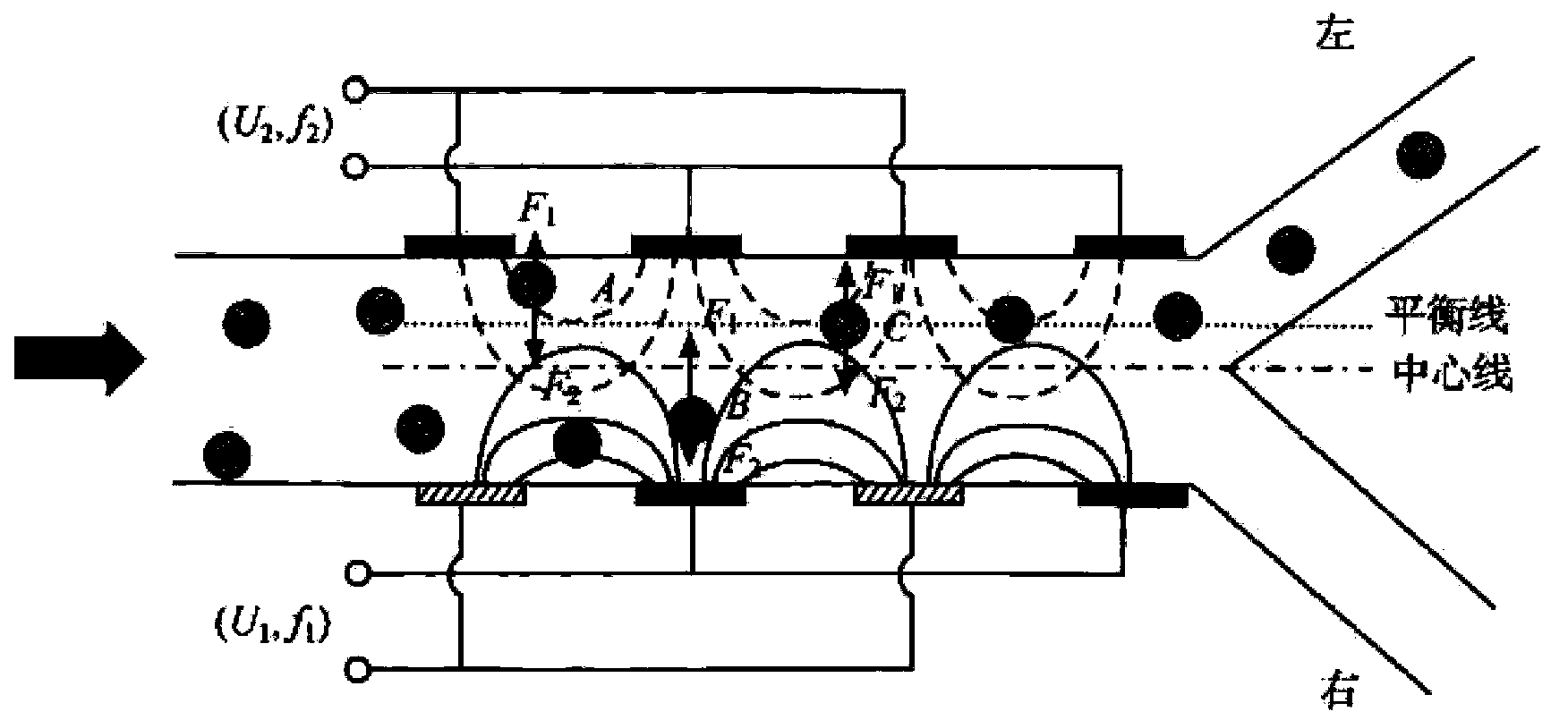

[0087] By adjusting the flow rate and pulse frequency of the dielectrophoresis microfluidic chip for specific and continuous separation of micro-scale particles, the movement of 5 μm particles and 3 μm particles under the inclined electrodes was obtained, as shown in Fig. Figure 12 It can be seen that the particles of 5 μm always move along the direction of the electrode inclination, by Figure 12 It can be seen that the component perpendicular to the direction of the electrode and the DEP force cancel each other out of the two components of the Stokes force, and the other component promotes the movement of the 5 μm particles along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com