Updraft multistage automatic cup distributing system

A multi-station, automatic technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high negative pressure, large floor space, and complex structure of the cup output components, and achieve reliable and timely output of cups. The effect of simplifying the structure and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

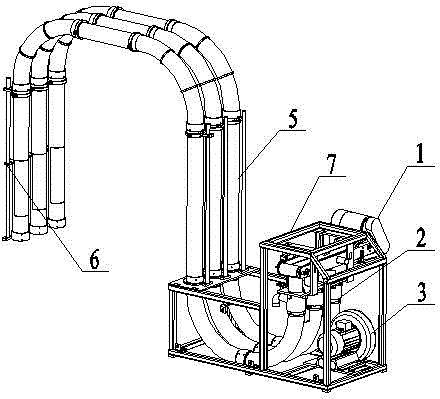

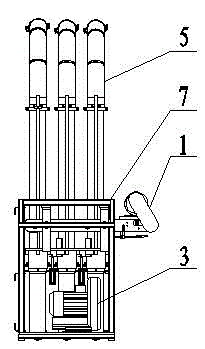

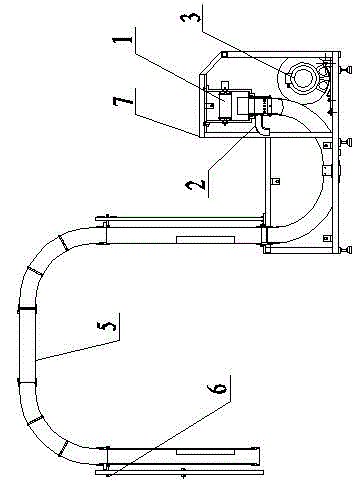

[0048] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the upper suction multi-station automatic cup dividing system includes an upper suction conveyor 1, a cup outlet assembly 2 and a fan 3. The upper suction conveyor 1 is set directly above the cup outlet assembly 2. 2 includes at least one cup outlet tube 201, the suction port of the fan 3 is connected with the upward suction conveyor 1, and the outlet of the fan 3 is connected with the cup outlet assembly 2. The upper suction conveyor 1, the cup out assembly 2 and the fan 3 are fixed on the frame 7

[0049] The upward suction conveyor 1 is arranged directly above the cup outlet assembly 2, and the paper-plastic cup 8 can directly fall into the cup outlet assembly 2 under the action of gravity, and there is no need to generate negative pressure inside the cup outlet assembly 2. The cup-out assembly 2 includes at least one cup-out barrel 201, which enables one cup-out assembly 2 to correspond to at least one su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com