Microorganism circulating oil recovery method adopting mode of continuously filling low-concentration nutrient solution

An oil displacement method and nutrient solution technology, which are applied in earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of unsatisfactory microbial oil displacement effect and discontinuous injection of nutrient solution, and overcome the problem of uneven nutrient concentration. Continuity, Enhanced Oil Recovery, Enhanced Oil Recovery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

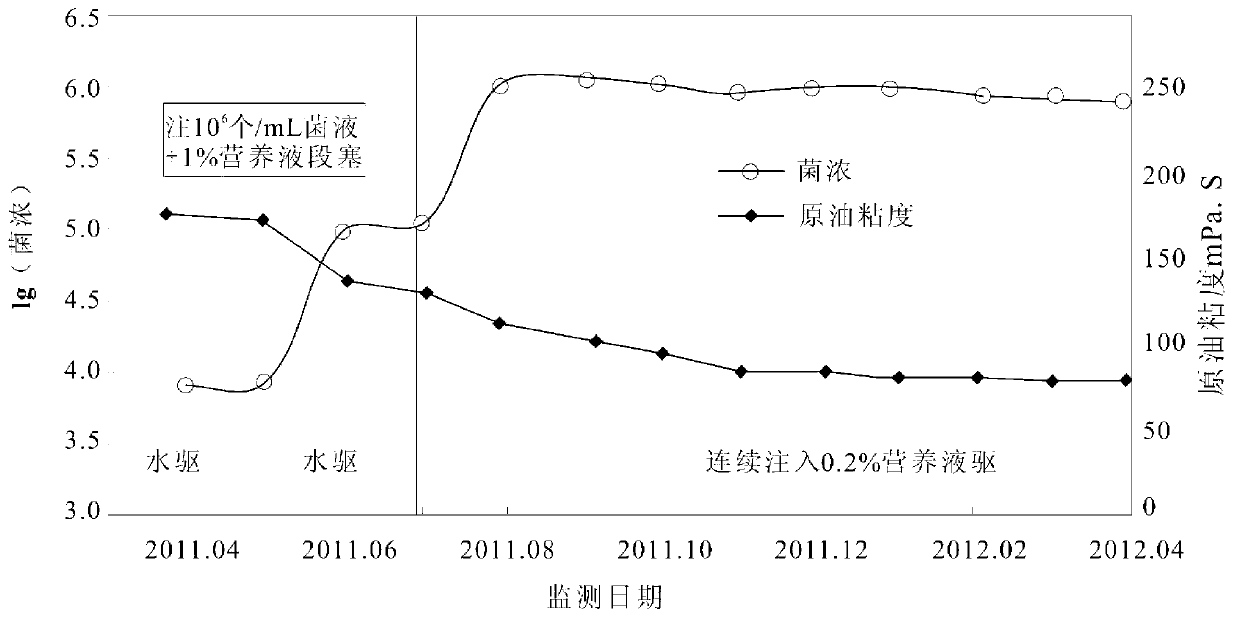

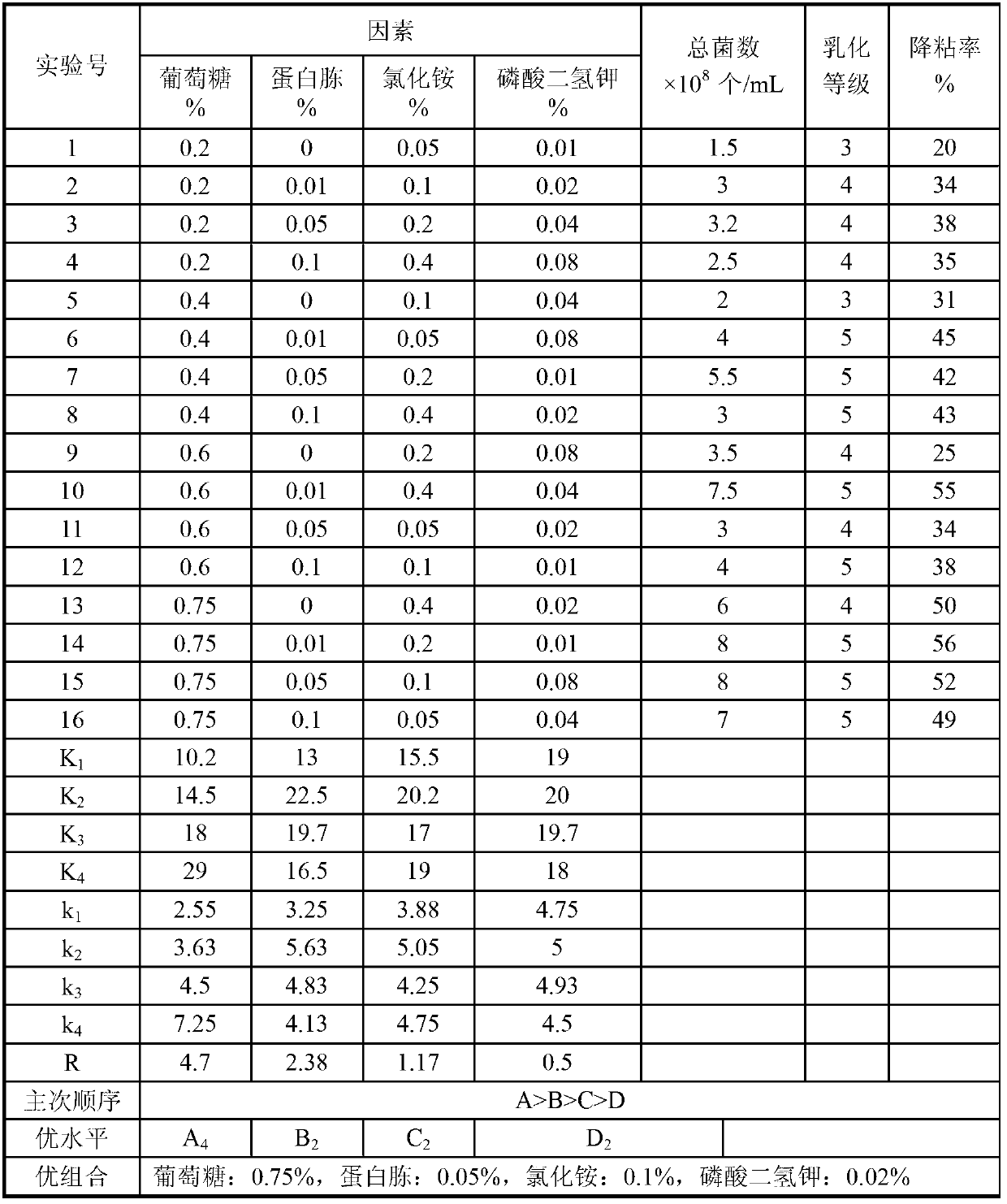

[0017] Embodiment 1: Taking the microbial circulation flooding method of continuously injecting low-concentration nutrient solution into Well Ba51-25 of Baolige Oilfield as an example, the present invention will be further described in detail.

[0018] Step A, the concentration of bacteria injected from the Ba 51-25 water injection well is 10 6 Each / mL of exogenous microbial bacterial solution and 1.0% nutrient solution slug 900m 3 , to make the target bacteria grow and reproduce in large quantities in the oil reservoir. The exogenous microorganisms injected are Bacillus subtilis (Bacillus subtilis) CGMCC 1.400 and Pseudomonas putida (Pseudomonas putida) CGMCC 1.1130, and the bacterial solution is Bacillus subtilis and putida The ratio of spores to bacteria is 1:1; the injected nutrient solution is 0.6% glucose, 0.1% peptone, 0.08% yeast extract, 0.1% ammonium chloride, 0.1% disodium hydrogen phosphate, 0.02% potassium dihydrogen phosphate, and formation water Preparation, th...

Embodiment 2

[0022] Example 2: Taking Bar 51-41 as an example to illustrate the oil displacement process of continuous injection of low-concentration nutrient solution to activate endogenous microorganisms

[0023] Step A, inject 1.2% nutrient solution slug 1200m from Ba 51-41 water injection well 3 To activate the endogenous microorganisms in the reservoir, the nutrient solution injected was 0.8% glucose, 0.1% peptone, 0.08% yeast extract, 0.12% ammonium chloride, 0.08% disodium hydrogen phosphate, 0.02% potassium dihydrogen phosphate, and Prepared with water, the total concentration is 1.0%. The injection speed is 30m 3 / day, followed by water flooding.

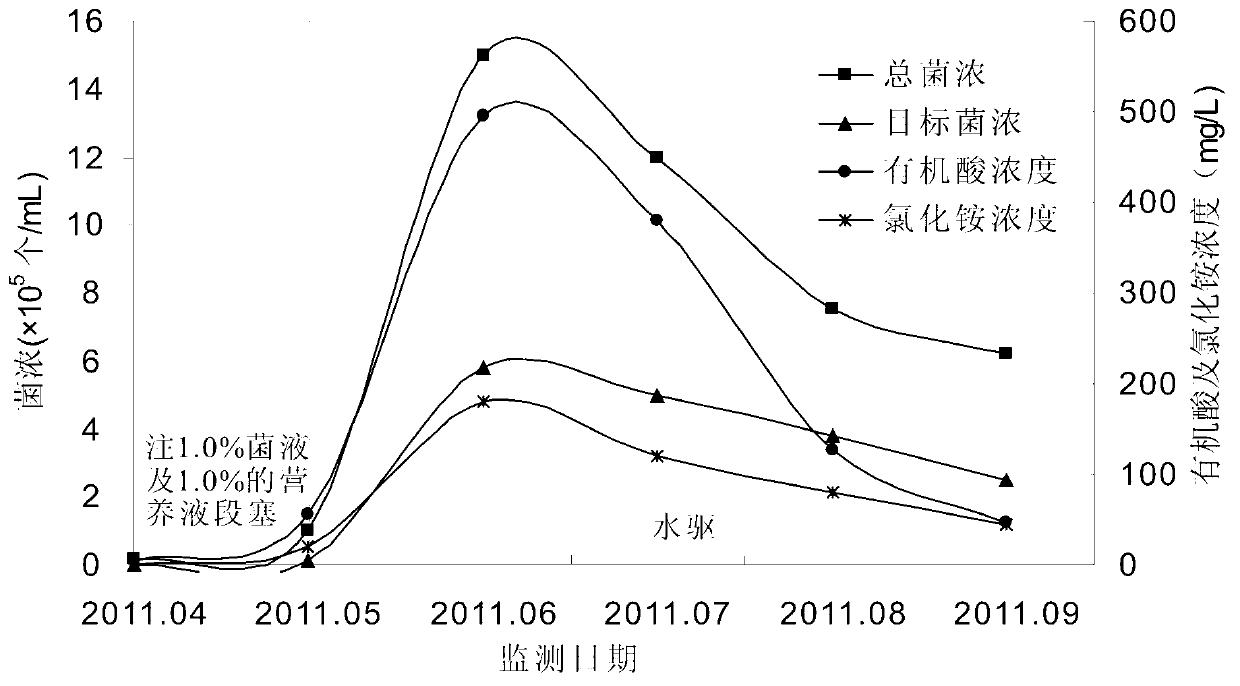

[0024] Step B, carry out the bacterial concentration and nutrient solution concentration in the output fluid of 5 oil wells corresponding to Bar 51-41, Bar 51-42, Bar 51-43, Bar 51-59, Bar 51-63 and Bar 51-71 Tracking and monitoring, it was found that the total number of bacteria in the continuous monitoring for 3 months was 5×10 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com